Adding Natural Light

by Marcy Marro | 1 April 2021 12:00 am

What you need to know about skylights and metal roofs

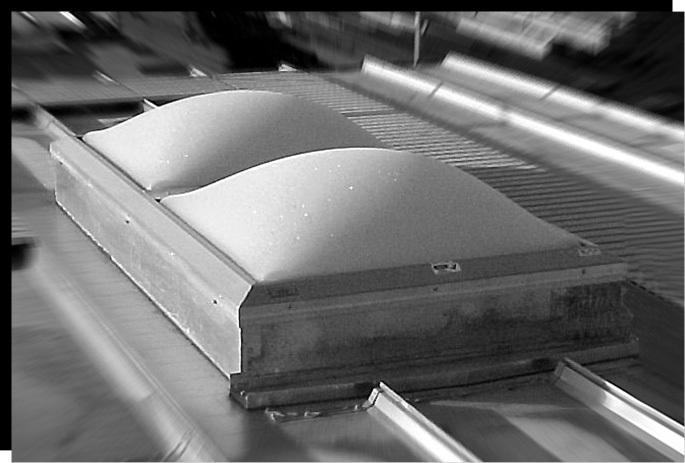

Photo courtesy of Velux America Inc.

Types of Daylighting Devices

There are two main ways to bring daylight into a building: skylights and tubular daylighting devices. A skylight is a dome mounted on a curb or seam integrated rails that allow light to transmit through. Similar to a traditional skylight are light transmitting roof panels, often called light panels, are typically translucent fiberglass panels shaped identical to the roof panel they are being installed within.

A tubular daylighting device, or TDD, is an optical system from top to bottom that uses both refractive and reflective optics to selectively harvest, transfer and deliver daylight to light building interior spaces. Optical devices such as the Solatube Daylighting Systems produced by Vista, Calif.-based Solatube International Inc.[1], are TDDs that selectively harvest beneficial angles of light from the sky to bring into a building for reliable and consistent daytime illumination, and selectively rejects angles of light that are not desired in a building, as well as rejecting wavelengths of energy, such as filtering out ultraviolet and heat-generating Infrared wavelengths of energy. A TDD is able to collect mass amounts of lights with a very small aperture, and actually ducts the daylight to where it’s needed within a building, so the rooftop aperture doesn’t need to be directly over the space that’s being daylit.

Metal Roof Compatibility

While all types of metal roofs can have skylights installed, Rodger Russ, NA sales manager–roof at Butler Manufacturing[2], Kansas City, Mo., says it really comes down to the panel manufacturer and the installing contractor for the proper installation, and not the panel profile. “It is typically best to contact the roof panel manufacturers for their recommendation or approved method to install skylights. Relying only on the contractor to make a recommendation can lead to improper installation and ultimately leaks.”

According to Brian Grohe, commercial sales manager for VELUX America Inc.[3], Fort Mill, S.C., the main considerations are the weight and size of the skylight unit and the structure underneath the roof. “The structure supporting the roof system is typically the most important element to consider when adding skylights onto metal roofs,” he explains. “This element will directly influence the size of the skylight, configuration of the curb and method of attachment.”

And, Grohe notes, the attachment method is the key differentiator in making sure the contractor gets a solid connection to the structure. Dimensions are also a key factor. “With metal roofs, we often use long, narrow skylights to limit the number of ribs on a metal roof to cut out, ultimately making the skylight easier to install.”

“The smaller the skylight, the more flexibility you have on where holes are cut and the attachment,” Grohe adds. “A smaller skylight typically means lower weight, but that’s not always the case as structural considerations have to be taken into account.”

Installation Factors

When installing skylights into a metal roof there are a few factors to consider. First is to understand what type of structural support is holding the roof up. “Whenever possible, we recommend installing skylights over structural steel members beneath the roof to help with weight deflection,” Grohe says.

Second, consider the roof profile and where the roof covers certain elements inside the building. This will help determine where on the roof the skylights should be installed. And, Grohe says, depending on how steep the roof pitch is, it may help or hinder the light disbursement from the skylights.

“Once you have an idea of the structure and how the roof pitch covers the roof, the final design consideration is maximizing the amount of skylight contribution to the desired lighting level for the building, while minimizing the number of holes in the roof,” Grohe says.

Finding that right balance of light quantity to roof openings will have the most significant impact on the energy savings potential.

Photo courtesy of Butler Manufacturing.

Skylight Installation

The process to install a skylight in a metal roof is determined by the type of curb or rails that is being used to support the dome. There are multiple types of curbs used for skylights and thus the type of curb will dictate the installation, explains Russ. In the case of seam-integrated rails, that too will have a different installation process. “The installation of the curb or the rails is the most critical part of the installation, as this is the area prone to leaking if not installed properly,” he says.

Curbs are typically installed directly on top of the metal roof and are sealed at the juncture. “However,” Russ says, “it is important to determine if flashings or trims are required on the interior of the skylight to prevent vapor drive from permeating the insulation system.”

And, Grohe says, they will try to provide a curb that will match the metal roof profile. “It’s extremely important to figure out the exact roof profile and rib spacing because the curbs have notches that lay around the ribs. There are also caps that go over the ribs and press the curb down to the roof, over the roof profile, to create the seal and hold the skylight in place.”

Upon determining a fastening method, all openings must be sealed with sealants or coatings. To ensure a good seal between the roof and the curb, Grohe recommends contractors use a sealant that is considered long lasting and will not degrade under UV exposure. Be sure to follow the manufacturers’ instructions regarding sealants.

“Butyl-based tapes and gun-grade sealants should be used for metal-to-metal connections as butyl is non-curring and non-skinning, but not UV stable,” Russ explains. “Urethane sealants should only be used in exterior applications as a belt and suspenders to protect the butyl sealant.”

Photo courtesy of Solatube International.

TDD Installation

The installation process for TDDs is not much different to that of a traditional skylight. As Neall Digert, Ph.D., MIES, vice president of Solatube International, explains, TDDs can use a pre-manufactured or site-built curb. Solatube Daylighting Systems, for example, have a curb cap flashing that allow it to be applied in the same way as other products. There are also self-flashing options designed to go onto the roof directly, with a flat flange that can be properly integrated with a building’s roofing system.

With the self-mount flashings, Digert says there are special instructions on how to apply it on a metal roof. But with a pitch roof, he says it’s important to maintain a dry edge of the self-mount flashing flange by either using an existing seam or creating a seam in the roofing to allow the dry flange to slide in underneath the roofing material.

Butyl tapes will make sure the roofing material and flashings are properly adhered to one another, and special grommets or washers would ensure any cut corners are properly protected and held in place. A flexible polyurethane sealant would protect the exposed edges to allow for the joint to remain watertight as the roof expands and contracts over time.

When it comes to metal roofs and flashing, Digert says standing seam metal roofs are the one roof type where they’d really want to think about how to integrate the standing seams into the flashing. “If there’s a narrow distance between standing seams, we would want to make sure that we have proper crickets to prevent ponding from the up-slope flashing side of the roof, and/or proper capping and sealing of the standing seams (ribs) to prevent water intrusion.”

Often, the preferred application for a metal roof is a curb-mounted application, where it’s easier to incorporate crickets to redirect water around the curb that supports a seamless curb cap flashing for the TDD product. “In this application we would have a dry edge, where the roofing material can either easily be interwoven with the curb assembly and, ideally, allows for a raised dry edge that is then protected by the TDD product’s curb cap flashing,” Digert explains. “The flashings protect the dry edge of the building envelope with a skirt that goes around the TDD’s curb cap flashing. Our flashings are seamless and are made out of a single piece of aluminized or special corrosion-resistant metals, and then are powder-coated to provide additional protection. There are no caulked joints exposed to the weather, allowing the dry edge of the TDD aperture and the building aperture to be fully contained within a watertight enclosure.”

Using butyl tapes and sealants, especially ones that are UV resistant, help maintain a number of different barriers to water intrusion. “And, with a metal roof,” Digert says, “we want to be careful with the expansion and contraction of the roofing system, and have a joint that is capable of addressing those dimensional changes over time.”

- Solatube International Inc.: https://www.solatube.com/

- Butler Manufacturing: https://www.butlermfg.com/

- VELUX America Inc.: https://www.velux.com/

Source URL: https://www.metalconstructionnews.com/articles/adding-natural-light/