Air Barriers and Metal Building Insulation

by Mark Robins | 1 February 2021 12:00 am

How do air barriers fit in with insulation and building envelope code compliance?

But many questions have surrounded the use of air barriers in metal buildings; for example, what makes them different from vapor barriers? How do they fit in with building envelope code compliance, and why should you care? Let’s dive into the basics of air barriers as they pertain to metal building insulation.

Air Barriers Defined

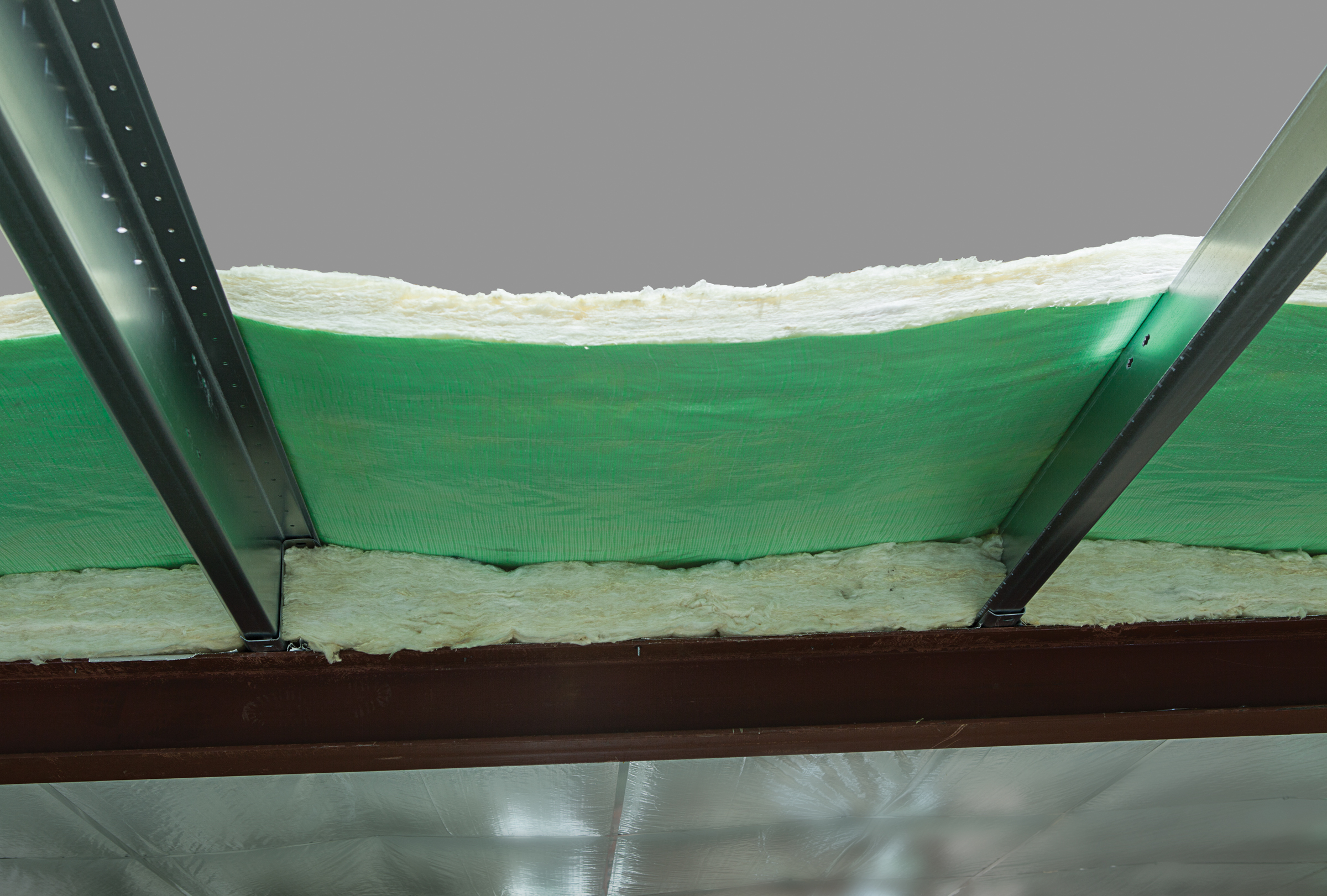

An air barrier is a material or system of materials designed to reduce uncontrolled air leakage and air infiltration through a building’s thermal envelope. Remember that the thermal envelope separates conditioned space and outdoor air. An air barrier can technically be comprised of different types of material and/or coatings, such as polyolefin. When an air barrier is assembled with a number of materials, then it becomes an air barrier system. As the Air Barrier Association of America (ABAA) notes, an air barrier “system essentially ‘wraps’ the building shell and ensures that it protects the building from the effects of air leakage.” Air barrier systems provide a barrier to not only water vapor, but also to “pollutants entering either the building or the building enclosure, such as suspended particulates, dust, insects, smells, etc.”

The purpose of an air barrier is to limit uncontrolled air leakage into and out of the building’s envelope. A building’s envelope is defined as a roof, wall and floor area that encloses a heated or cooled area. Uncontrolled leakage will result in increased energy usage due to the heat or cooling lost. In the 1930s, the University of Minnesota did a study on leakage through framed walls, resulting in the first acceptance and use of paper weather barriers. Unfortunately, over the next seven decades, the concept and correct use was lacking in building science and training for contractors, resulting in many building failures. In the 1970s, however, an oil embargo led to the construction industry becoming more focused on adding insulation and vapor barriers to conserve energy.

An air barrier can be placed on the interior side, exterior side, somewhere within assemblies composing the envelope, or any combination thereof. When placed within the assembly, the air barrier is protected from damage by trade workers who cannot poke holes in it as they might in exposed vapor retarders. This means that the system provides a fully sealed airtight envelope.

Vapor Barriers Versus Air Barriers

Vapor barriers, also referred to as vapor retarders, control water vapor, a gas, from entering the thermal cavity. Its ability to do so is measured in perm ratings. A true vapor retarder should be between 0.09 and 0.02 perms.

Air barriers are used to control air movement from inside and outside the thermal envelope. Most materials used are measured under ASTM E2178. If the air barrier is placed within the thermal envelope, the perm rating should be between 15 and 25 perms. This allows water vapor to carry its moisture through the air barrier and not trap moisture.

In many climate zones, the vapor barrier is placed on the inside (warm side) of the thermal envelope. However, some climate zones require the vapor barrier to be placed on the outside (warm side). Examples include southern Florida and Hawaii. These climate zones have warm, moist air outside the thermal envelope and require different approaches to air tightness and systems.

First, a building designer must identify the air barrier. A vapor retarder can be designated as both an air barrier and as a vapor retarder. If a designer chooses to use an air barrier separate from the vapor retarder, the air barrier then cannot be a vapor retarder and must be a breathable barrier. In essence, the air barrier design needs to be amped up a notch to go further than a vapor retarder if it’s appropriated separately.

Air Barriers and Commercial Code Compliance

The most adopted, new code cycle, IECC 2018/ASHRAE 90.1-2016, now requires buildings to have an air barrier in the thermal envelope, and for it to be indicated in drawings.

As insulation cavity thicknesses increase with code advancements, the location of the dew point is slowly migrating to within the cavity, instead of somewhere on the surface of the insulation facing, particularly for preengineered metal buildings. Air barriers greatly control the rate at which air containing moisture migrates though the insulation cavity.

Air barriers must be contained within the thermal envelope and can be installed on the interior, exterior surface, within the assembly, or any combination thereof. It is critical for air barriers to be continuous for all assemblies and across all joints in the assemblies.

Bill Beals is a district manager and energy codes specialist at Therm-All Inc., North Olmsted, Ohio. To learn more, visit www.therm-all.com[1].

- www.therm-all.com: http://www.therm-all.com

Source URL: https://www.metalconstructionnews.com/articles/air-barriers-and-metal-building-insulation/