Bare Metals Winery

by Christopher Brinckerhoff | 1 March 2022 12:00 am

A metal building system creates a modern industrial winery design

Photo: Matt Swain Photography, Salem, Ore., www.mattswainphoto.com[1]

Tight Site

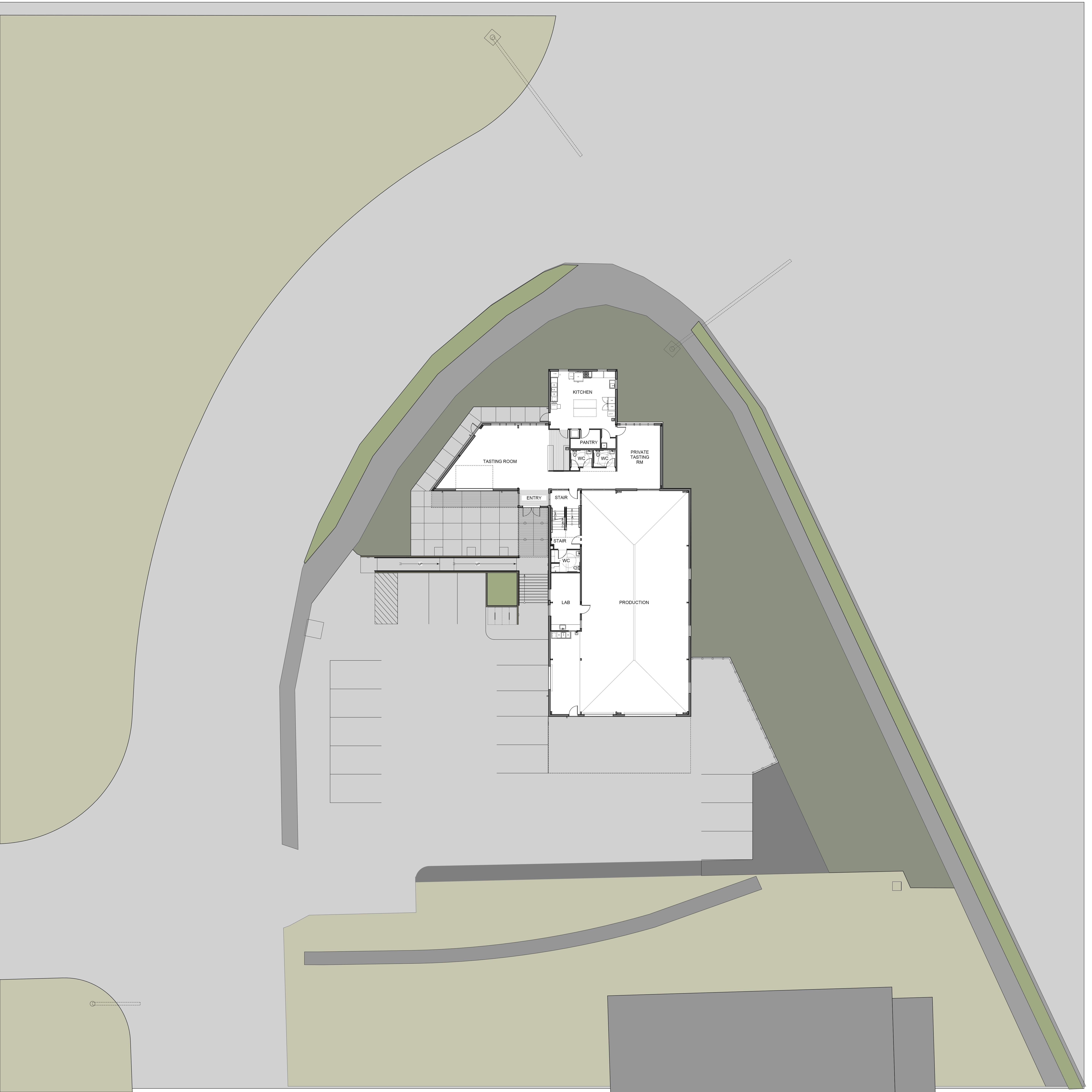

The first thing the design team had to contend with was orienting the building into the concave side of curved roadways. The site abuts streets on three sides, South St. Paul Highway on the east side and Industrial Parkway on the north and west sides. The entrance and parking lot are on the south side.

Jason Didion, designer, senior project lead at Telford + Brown Studio Architecture in Portland, Ore.[2], says, “This property was kind of a remnant from when the adjacent intersection was reconfigured. That’s what created this weird little triangle piece of property. Our biggest challenge as we were looking at this property was figuring out how to fit the building on the site and take advantage of the little room we had. We didn’t have any flexibility in where the existing access was. And it was a sort of a rats’ nest of existing easements and setbacks and already existing utility lines, so we were pretty hemmed in where it is.”

The solution was to place the entrances to the tasting room portion and production space both on the south side. The building is organized in several sections.

“The general form of the building we wanted to be somewhat dynamic, especially from the highway,” Didion says. “As you’re traveling north into town, you see the building on your left, and it’s not a square, industrial building. It’s pretty active the way that it’s angled and sloped. Even though that’s the plainest side of the whole structure, as you enter Industrial Parkway and come around the west side of it, the volumes break up quite a bit, yet stay pretty active. In essence, it’s a pretty simple industrial building with a few tweaks to give it a little more interest than what you would normally have.”

The building materials selection includes smooth IMPs and corrugated, vertically oriented wall panels.

Photo: Matt Swain Photography, Salem, Ore., www.mattswainphoto.com[1]

Metal Building Solution

Since the owner wanted a large, flexible space for production, a metal building system was used. It became clear as the project progressed that the metal building system could be used for the other parts of the building as well.

“Talking with the general contractor and metal building supplier, we realized that we could achieve any level of finish or refinement in that tasting room with a steel building just as well as a traditional building,” Didion says.

Erectors Inc., Milwaukie, Ore.[3], erected a metal building system supplied by Web Steel Buildings Northwest LLC in Sandy, Ore.[4] Importantly, the building has four levels, says Josh Komp, owner at Cornice Construction LLC, Scappoose, Ore.[5] “The structure has four different floor levels: an underground wine storage area, kitchen and tasting area, production floor, and an upstairs office and storage mezzanine. Coordinating all those elevations changes in the metal building design was complicated. We had to have four different bearing elevations for the columns and had to build concrete pilasters in some instances to accommodate them.”

In addition to providing the aesthetics the designers wanted, by building the entire facility with a metal building, the construction process was simplified. In terms of the design, using a metal building for the tasting room and leaving it exposed contributed to a modern, industrial appearance.

“It refined our design aspect even further in that one of the things the owner really wanted to do was to include the production aspect of the building in the experience of people coming to the tasting room,” Didion says. “This winery is in a light industrial area in the city limits, so it’s got a different feel than an old barn out in the country that’s been converted a winery. It allowed us to carry a little bit of that industrial feel into the tasting room while still refining those finishes a bit more. I think it makes the building a bit more cohesive so that when you are in the tasting room, you are fully aware that there’s production going on.”

An oversized canopy that shelters the winery’s crush pad features tapered beams. Photo: Matt Swain Photography, Salem, Ore., www.mattswainphoto.com[1]

Cantilevered Canopy

In addition to the exposed structure inside the building, another element that expresses its modern, industrial design is an oversized canopy that hangs over the service doors to the production space. The 50-foot-long by 20-foot-wide, cantilevered canopy provides sheltered space for a wine crush pad. Its beams are tapered. To build it, Komp says, “The beams are tapered and they are at an angle. The facia follows the pitch of the roof. The taper in the beam is what gives it more depth.”

To build the canopy, Erectors used pre-engineered metal building components and Salem, Ore.-based Taylor Metal Inc.’s[6] 26-gauge PBR panels in Zincalume. For the soffit, the company installed 12-inch-wide, 24-gauge Lifetime soffit panels in Glacier White. Another canopy by the tasting room has soffits with reclaimed cedar vineyard stakes.

Chris Clements, sales/project manager at Web Steel Buildings Northwest, says, “One of the best features is the cantilevered canopy over the crush pad. In Oregon, especially at harvest time, it can be pouring down rain, and that big awning provides plenty of functional cover for workers without columns interrupting the workspace and, at the same time, providing an imposing design feature to the building.”

Multiple Metal Elements

For the building’s roof, Erectors installed Taylor Metal’s 18-inch-wide, 24-gauge MS-200 standing seam roof system in Zincalume. At soffits, Erectors installed Taylor Metal’s Lifetime metal soffit panels.

“We also designed the roof structure to allow for and installed solar panels which pay for most of the power usage at the facility,” Komp says.

Around the whole building exterior with the exception of the kitchen portion, Erectors installed Taylor Metal’s 26-gauge, 36-inch-wide, 7/8-inch corrugated wall panels in Zincalume.

At the kitchen portion of the building, Erectors installed Houston-based MBCI’s[7] 3-inch-thick, 36-inch-wide CF Architectural IMPs with a stucco-embossed finish in Silver Metallic.

“One interesting part is we made the kitchen area with the IMPs have a 5-foot parapet with an internal gutter in order to hide all the roof equipment from the street,” Komp says.

At the production portion, Cornice Construction installed two of Daytona Beach, Fla.-based Service Partners LLC’s[8] insulated section metal doors in blue. The doors have Bluetooth-enabled locksets.

Additionally, Vancouver, Wash.-based Anderson Glass Co.[9] installed windows and a clear anodized aluminum storefront system.

Roadways bordering three sides of the site are a driver of the design.

- www.mattswainphoto.com: http://www.mattswainphoto.com

- Telford + Brown Studio Architecture in Portland, Ore.: http://telfordbrownstudio.com/telford-brown-studio-architectureportland-house.html

- Erectors Inc., Milwaukie, Ore.: https://www.erectorsinc.com/

- Web Steel Buildings Northwest LLC in Sandy, Ore.: https://wsbnw.com/

- Cornice Construction LLC, Scappoose, Ore.: https://www.corniceconstruction.net/

- Salem, Ore.-based Taylor Metal Inc.’s: https://taylormetal.com/

- Houston-based MBCI’s: https://www.mbci.com/

- Daytona Beach, Fla.-based Service Partners LLC’s: https://www.service-partners.com/

- Vancouver, Wash.-based Anderson Glass Co.: https://www.andersonglass.com/

- www.telfordbrownstudio.com : https://www.telfordbrownstudio.com

- www.andersonglass.com : https://www.andersonglass.com

- www.erectorsinc.com : https://www.erectorsinc.com

- www.service-partners.com : https://www.service-partners.com

- www.wsbnw.com : https://www.wsbnw.com

- www.mbci.com : https://www.mbci.com

- taylormetal.com : https://taylormetal.com

Source URL: https://www.metalconstructionnews.com/articles/bare-metals-winery/