Beyond Safety Training

by Jonathan McGaha | 30 November 2015 12:00 am

The importance of training employees goes beyond just avoiding OSHA fines

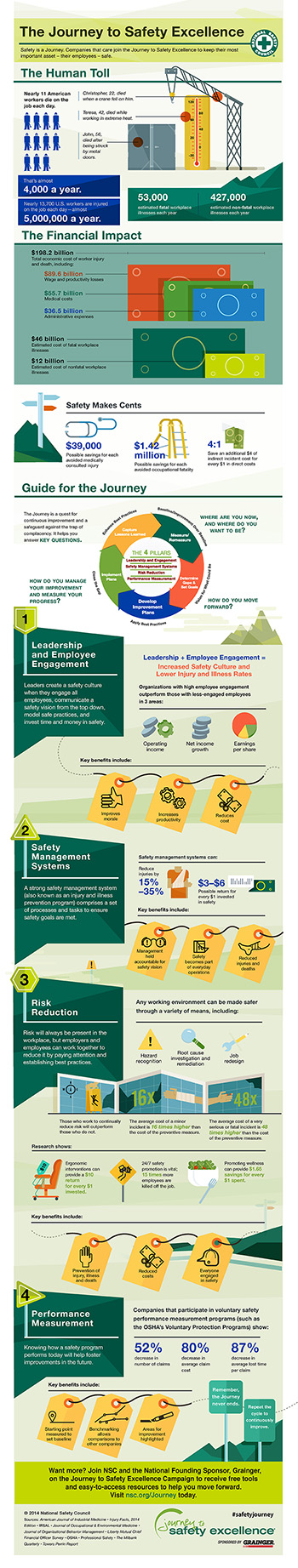

In building and construction especially, workplace safety is a critical aspect of the job. According to the National Safety Council[1] (NSC), more than 10 workers die on the job each day, and 4.8 million are injured annually. The council also estimates that there are more than 50,000 fatal workplace illnesses and 400,000 nonfatal workplace illnesses that occur each year.

In building and construction especially, workplace safety is a critical aspect of the job. According to the National Safety Council[1] (NSC), more than 10 workers die on the job each day, and 4.8 million are injured annually. The council also estimates that there are more than 50,000 fatal workplace illnesses and 400,000 nonfatal workplace illnesses that occur each year.

The Occupational Safety and Health Administration[2]

(OSHA) notes that quality safety and health training helps prevent work-related injuries and illnesses. Effective training also encourages workers by educating and empowering them to advocate for safer working conditions.

In effective training, OSHA says participants should learn how to identify the safety and health problems at their workplace; how to analyze the causes of these safety and health problems; how to bring about safer, healthier workplaces; and how to involve their co-workers in accomplishing all of the above.

[3]“It’s a matter of educating the work force on what the real hazards are, focusing on the simplest and effective ways to control the hazards, and then making sure that they stay fixed,” says Regina McMichael, CSP, CET, president of The Learning Factory Inc.[4], a safety and risk education and training company in Clemson, S.C. “That means outfitting people with the right tools, the right equipment and the right capabilities to be able to fix hazards when they are identified quickly, as opposed to ignoring them until they become overly problematic.”

[3]“It’s a matter of educating the work force on what the real hazards are, focusing on the simplest and effective ways to control the hazards, and then making sure that they stay fixed,” says Regina McMichael, CSP, CET, president of The Learning Factory Inc.[4], a safety and risk education and training company in Clemson, S.C. “That means outfitting people with the right tools, the right equipment and the right capabilities to be able to fix hazards when they are identified quickly, as opposed to ignoring them until they become overly problematic.”

Safety training goes beyond a legal and compliance standpoint as a way to avoid OSHA fines. It’s a way to make sure your employees are safe on the job site and go home to their families every night. Stephen Yates, founder and president of Optimum Safety Management[5], a full-service safety consulting firm in Naperville, Ill., says that in general, the frequency of a contractor being cited by OSHA and having fines and penalties levied against them is minimal compared to the exposures and risks that happen each and every day on a job site that having a safety program can actually mitigate.

“And that relates to the exposures to their workers and the exposures to other contractors on the job site they could injure and suffer a lawsuit from,” he explains. “So it’s extremely important just from protecting their own workers.”

Importance of Safety

Before he teaches OSHA 10- and 30-hour classes, Craig Shaffer, CSP, president of Safety Works Inc.[6], an occupational safety training and consulting company in Dillsburg, Pa., always discusses why companies do safety. “To me,” he says, “if we’re not all on the same page with regards with why we do safety, then the rest of the class doesn’t mean as much. I always want folks to understand the reason we do safety is not because we are afraid that OSHA is going to come around the corner, it’s to go home at the end of the day. There are people who care about us and love us and need us to be home at the end of the day. That’s why we do these things. Good business is important as well.”

There are three good reasons for why companies need to do safety. “One, for ourselves and our family,” Shaffer says. “Two, it’s good business. And three, it’s the law, if the other two reasons aren’t good enough.”

However, McMichael explains that a lot of individuals and companies tend to default back to the threat of OSHA compliance for the reason to be safe. “The reason we should be safe is because we want to take care of our workers and keep them alive, and achieve a profitable business because everyone comes to work and goes home safely, not because there’s some kind of legal mandate behind it,” she says.

Safety and Profitability

While it may not seem like it, safety and profitability are directly linked. McMichael says smaller companies may have a harder time to seeing the connection since they usually don’t have a high frequency of loss. However, in reality, she says, there is statistical data showing that for every dollar spent on direct costs to the loss-meaning workers’ comp or money out of pocket-an accident can cost a company anywhere from four to 10 times the original cost.

Workers’ compensation claims are very expensive, and Yates notes that because of how rates are calculated, a claim can impact a contractor’s bottom line for potentially up to four years.

For example, McMichael says, if someone gets hurt, even if it’s a minor injury, then you have to provide first aid, maybe have someone take the person to the hospital. “At a minimum, it’s going to disrupt your work schedule,” she explains. “Worse case scenario, something horrible happens, or maybe even the guy’s just off of work for a few days, that affects your profitability, that affects your scheduling, that affects your capability to hit your mark. Those aren’t just a part of doing business; those can’t be scheduled and managed.”

Another reason safety and profitability are tied together is that when an accident results in a workers’ compensation claim, the cost of insurance goes up in the future, which comes off the bottom line. To put it simply, Shaffer says, “If we’re not paying OSHA fines, if we’re not having people hurt and having to pay more for our insurance, that’s all money that stays in the company. If we are getting OSHA fines and are paying more for our workers’ comp, that’s money that is coming out of profit.”

Safety Management Systems

According to the NSC, a strong safety management system comprises a set of processes and tasks to ensure safety goals are met. Safety management systems can reduce injuries by 15 to 35 percent, while offering a $3 to $6 possible return for every

$1 invested in safety.

The NSC notes that a safety management system is a systematic, explicit and comprehensive process for managing safety risks that provides for goal setting, planning and measurement of performance against defined criteria. It is also a formal method of measuring and evaluating individual and organizational safety performance with an emphasis on continuous improvement.

There are four aspects of an effective safety management system:

- Reduces the risk of workplace incidents, injuries and fatalities through data-driven measurements and improvements

- Involves engaging people and working in partnership to make safety a shared responsibility, recognizing the value of cross-level teamwork.

- Is organized and structured to ensure organizations are able to achieve and maintain high standards of safety performance.

- Is proactive, preventive and integrated into the culture of an organization.

Yates stresses the importance of differentiating between a safety program and a safety management system. At Optimum Safety Management, the safety management system is made up of management commitment, program development, training, safety surveys and corrective action. “We really want to see contracting firms get more of a systematic approach, rather than just having a compliance document,” he says.

Similar to quality systems, Yates notes that safety management requires planning and forethought. “If we run safety like we do quality, we think about what we are doing ahead of time, we make sure that we are doing it properly and effectively and safely before we do it,” he adds. “It requires that we have a process for how we’re doing the work that we’re doing.”

|

Roadmap for Continuous Safety Improvement About a year ago, the National Safety Council[7] launched its Journey to Safety Excellence[8] campaign to educate employers on the importance of workplace safety. Based on 100 years of experience, it provides a model and methods for cultivating committed leaders and engaged employees; safety processes and procedures that are embedded in operations; active removal of risk in the workplace; and sound measurement of both lagging and leading indicators of safety performance. The campaign provides safety practitioners access to tools and resources that help organizations of all sizes and levels of safety maturity pinpoint areas of weakness and capitalize on areas of strength. According to Amy Harper, director of workplace safety initiatives at NSC, the campaign’s goal is to also demonstrate the value of investing in safety, or understanding what the return on investment business owners and executives can make by investing in certain aspects of safety. “We also want to provide them with a road map for continuous improvement,” she adds. “How do you take where you are right now, measure where you are right now with your safety program, and then how do we get you to the next level, and what are the steps for doing that?” There are four pillars that make up the Journey to Safety Excellence. The core of the NSC improvement model, the four pillars are interdependent and when fully integrated as a workplace safety strategy, have a significant impact on protecting employees and enhancing organizational performance and profitability. • Leadership and employee engagement Leaders foster a culture where safety is fully integrated in the business and is a core value where all employees are engaged and share responsibility. • Safety management systems A strong safety management system is a framework of processes and procedures to ensure that work tasks are completed safely to achieve objectives. • Risk reduction Risk is the combination of the probability of an event and the severity of the injury that may result. Risk is always present in the workplace and those organizations who actively strive to reduce it will outperform those who do not. • Performance measurement To manage improvement, it is essential to have measurable goals to track performance, looking at leading and lagging indicators and how they are related. To learn more and to join the journey for free, visit |

Be Proactive

Shaffer notes that more than anything; commitment from the company is essential to the success of any safety program. “You can have preplanning, you can have training, and all that stuff,” he says, “but if you don’t have owners and management

that are dedicated to safety, or that believe in it, you’re going to struggle to accomplish what you really want to accomplish.”

Accountability between owners and management play a big part in the success of any safety program. “Some people view safety proactively as an investment, and they typically have good, effective safety programs, and other people look at it as something they have to do for a project, and they’re going to struggle to accomplish what a good safety program can do,” Shaffer explains. “If you look beyond just the requirements of what a project may entail, there’s a lot of money to be saved through safety. Yes, there’s an investment involved upfront, but if you’re really dedicated to the safety effort, there’s a lot of money that can be saved by preventing folks from getting hurt and by preventing OSHA fines.”

If contractors don’t keep up with other firms that are being proactive, Yates says they risk losing their employers for a more proactive contractor. Employees are starting to pick up on the difference between working for a safe versus unsafe contractor. “It’s palpable in the environment when you walk into it,” he says. “[Employees] definitely want to work for contractors who are following good safety practices. When you train your employee and bring them up to speed on how you do things, your trade and craft, and then you lose them to the firm across town, that’s a significant loss in your training dollars and you’re starting all over again with new employees.”

Companies that choose to be proactive in their safety programs can actually make a safety a profit center, McMichael says. The problem is that most companies can’t wrap their head around that concept. “They see it strictly as OSHA fines or buying equipment, instead of saying, if my guys can get up there, do the work and do it faster, and not be under any threat of a safety hazard, then they’re going to be more efficient, they’re going to work better and we’re going to get onto the next project quicker,” she says.

“Good management has to do with taking the tools of your program and making them work,” Shaffer adds. However, he says every company is different. “While some pieces of the puzzle may be the same,” he says, “how they come together and what works for one company may be different for another company.”

- National Safety Council: http://www.nsc.org/pages/home.aspx

- Occupational Safety and Health Administration: https://www.osha.gov/

- [Image]: http://WorkplaceSafety-large.jpg

- The Learning Factory Inc.: http://thelearningfactory.me/

- Optimum Safety Management: http://www.oshasafetymanagement.com/

- Safety Works Inc.: http://www.safetyworksinc.com/

- National Safety Council: http://www.nsc.org/pages/home.aspx?var=mnd

- Journey to Safety Excellence: http://www.nsc.org/measure/pages/journey-to-safety-excellence.aspx?utm_medium=(none)&utm_source=(direct)&utm_campaign=journey

- www.nsc.org/journey: http://www.nsc.org/measure/pages/journey-to-safety-excellence.aspx?utm_medium=(none)&utm_source=(direct)&utm_campaign=journey

Source URL: https://www.metalconstructionnews.com/articles/beyond-safety-training/