How Butyl Tape Extends Metal Roof Longevity

by Christopher Brinckerhoff | 31 March 2025 6:00 am

[1]Metal roofs are known and trusted for their durability and longevity. When installed correctly, they can have an average lifespan of more than 50 years. However, metal roofing is not immune to challenges such as leaks, corrosion, and thermal movement despite its strength. Over time, exposure to the elements can compromise seams, fasteners, and flashing points, leading to costly repairs and reduced lifespan.

[1]Metal roofs are known and trusted for their durability and longevity. When installed correctly, they can have an average lifespan of more than 50 years. However, metal roofing is not immune to challenges such as leaks, corrosion, and thermal movement despite its strength. Over time, exposure to the elements can compromise seams, fasteners, and flashing points, leading to costly repairs and reduced lifespan.

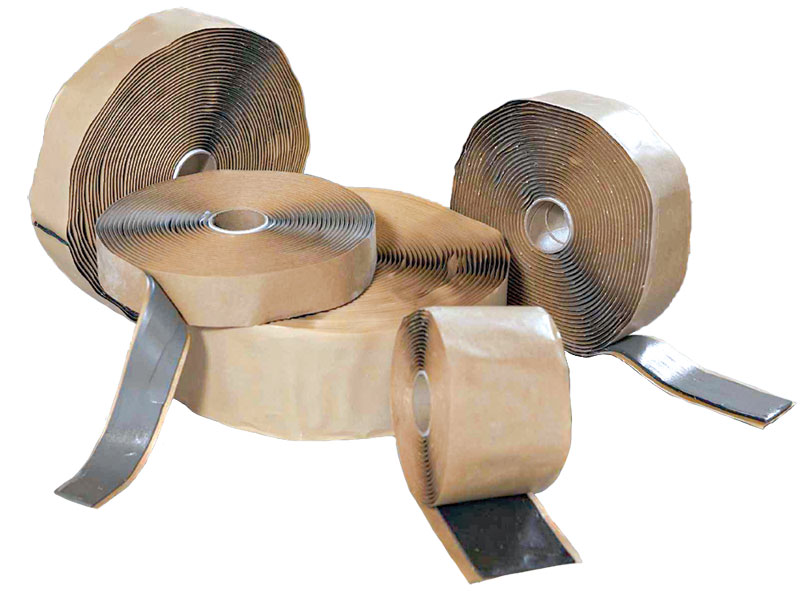

One of the most effective ways to mitigate these risks and protect and extend the lifespan of a metal roof is by using butyl tape. This high-performance sealing solution provides waterproofing, flexibility, and corrosion resistance, making it essential for preserving metal roofing integrity.

[2]

[2]Addressing the everyday challenges of metal roofing

Metal roofs are constantly exposed to environmental factors, causing wear and tear over time, leading to leaks, corrosion, and structural damage.

One of the primary concerns is water infiltration. Metal roofs have many seams, fasteners, and penetration points, all potential entry points for water and windblown debris, especially during heavy rain, high winds, snow, or ice build-up. If left unsealed, moisture can seep into the gaps, and particulate matter can accumulate, leading to rust formation, insulation damage, and interior leaks.

Another challenge with metal roofs is thermal expansion and contraction. The metal expands when exposed to heat and contracts when temperatures drop. This constant movement can cause fasteners to loosen, seams to shift, and gaps to develop over time. Although metal roofs are designed to move in sync thermally, deviations during construction impede the design and lead to problems like oil canning. These gaps can lead to air leaks, water penetration, and long-term structural deterioration without an effective sealing solution.

Structural weakness from wind and weather is also key to metal roof longevity. High winds, heavy rainfall, and snow can stress fasteners and seams, potentially leading them to become loose and increasing the risk of failure. If they are not properly sealed, it can allow moisture infiltration, leading to long-term damage.

[3]The role of butyl tape in metal roof protection

[3]The role of butyl tape in metal roof protection

Butyl tape is a non-hardening sealing material that provides long-term protection against water, air, and corrosion. It offers permanent flexibility, strong adhesion, and superior weather resistance, making it an ideal solution to address key vulnerabilities in metal roofs. Here is the role butyl tape plays in reference to key accessories in metal roofing construction:

Sealing roof seams and overlaps: Metal roof panels often have overlapping seams, which are vulnerable to water penetration. Butyl tape fills gaps and seals edges, ensuring no moisture seeps through and a watertight bond between metal sheets. Its adhesive properties allow it to remain fixed to the substrates, while its cohesive properties enable it to stretch with unwanted movement.

Fastener protection: Screws and bolts are common weak points where water can pool and penetrate the substrate. Driving fasteners through a point in the substrates where the butyl tape is present creates a watertight seal, preventing water intrusion and corrosion.

Gutter and flashing sealing: Metal gutters and flashings are prone to leaks and water damage over time. Butyl tape effectively adheres to metal and other surfaces, providing an airtight and watertight seal around these areas and preventing leaks at the joints.

Ridge cap and end-lap seals: These elements are constantly exposed to wind-driven rain and snow. Butyl tape provides extra reinforcement to keep moisture out and protect roof edges.

Unlike rigid sealants, butyl tape adapts to metal expansion and contraction, reducing joint stress. It also conforms to irregular surfaces for a secure seal, minimizing the chances of gaps forming due to thermal cycling. Because its functionality remains constant over time, so will its ability to hold panels and seal around penetrations and seams.

Designed to withstand rain and snow, butyl tape does not crack or degrade over time. It maintains its flexibility and tackiness, even in fluctuating temperatures. Non-skinning butyl tapes are designed to be placed between opaque substrates. They are not topical sealants and long-term UV exposure will degrade butyl sealants. If the application calls for a topical sealant, a skinning butyl, hybrid, silicone, or polyurethane will be required.

[4]

[4]Best practices for installing butyl tapes

To maximize the effectiveness of butyl tape, the below key application guidelines should be followed:

Choosing the right butyl tape: Not all butyl tapes are the same, and different applications may require specific formulations, thicknesses, or widths. Selecting the right tape for each application ensures long-term performance. Select the appropriate width, thickness, strength, and type based on the project’s requirements. Refer to the details from the panel manufacturer to determine the correct tape size.

Surface preparation: Clean the metal surface thoroughly to remove dirt, dust, oil, and grease. Any residue or contaminants can limit the product’s effectiveness. Allow panels time to dry. Ensure the area is completely dry before applying the butyl tape.

Proper placement and pressure application: Apply the butyl tape directly from the roll and use even pressure along seams, joints, or fasteners. Press firmly to ensure a strong, airtight bond with the metal surface. Remove the release paper backing after applying it to the surface prior to laying it on the covering panel.

Ensuring airtight adhesion: Use a roller or hand pressure to eliminate air pockets and create a tight seal. Allow a short settling period before exposing the tape to weather conditions. After installation, inspect all seams and joints to ensure complete coverage.

Storage and handling: Store in a cool, dry place away from direct sunlight and extreme temperatures. Avoid folding or creasing the tape.

[5]

[5]Butyl tape–an effective and lasting metal roofing solution

Metal roofing continues to gain popularity for its durability and efficiency, and proper installation is key to maximizing its lifespan.

By integrating butyl tape into metal roofing installations, contractors and building owners can extend roof longevity, reduce maintenance costs, and improve weather resistance. With its superior adhesion, durability, and long-lasting performance, butyl tape is a key component in the future of metal roofing.

Miguel Pena is the business development manager with H.B. Fuller[6]. Miguel has 18 years of product development and sales experience in butyl sealants for the metal construction industry. He was formerly the owner of GSSI Sealants, which was acquired by H.B. Fuller in 2022. Miguel has also been a board member of the Metal Construction Association, holding multiple chair positions over the years, most recently for METALCON.

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/03/Roof-2.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/03/Butyl-Tapes-2.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/03/Roof-1.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/03/GettyImages-183823732.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/03/GettyImages-1172164873.jpg

- H.B. Fuller: https://www.hbfuller.com/en

Source URL: https://www.metalconstructionnews.com/articles/butyl-tape-metal-roof/