Coil Anodized Aluminum

by Mark Robins | 1 February 2023 12:00 am

Achieving durable, elegant, consistent appearance

How Coil Anodized Aluminum is Created

While raw aluminum naturally produces an oxide layer that protects it from corrosion, pre-anodized aluminum creates an anodic layer that is considerably harder, thicker, and more translucent. Through a tightly controlled electrochemical process, coil anodized aluminum grows an oxide layer from the base aluminum. Converting aluminum into aluminum oxide, this process binds the anodized layer at the molecular level.

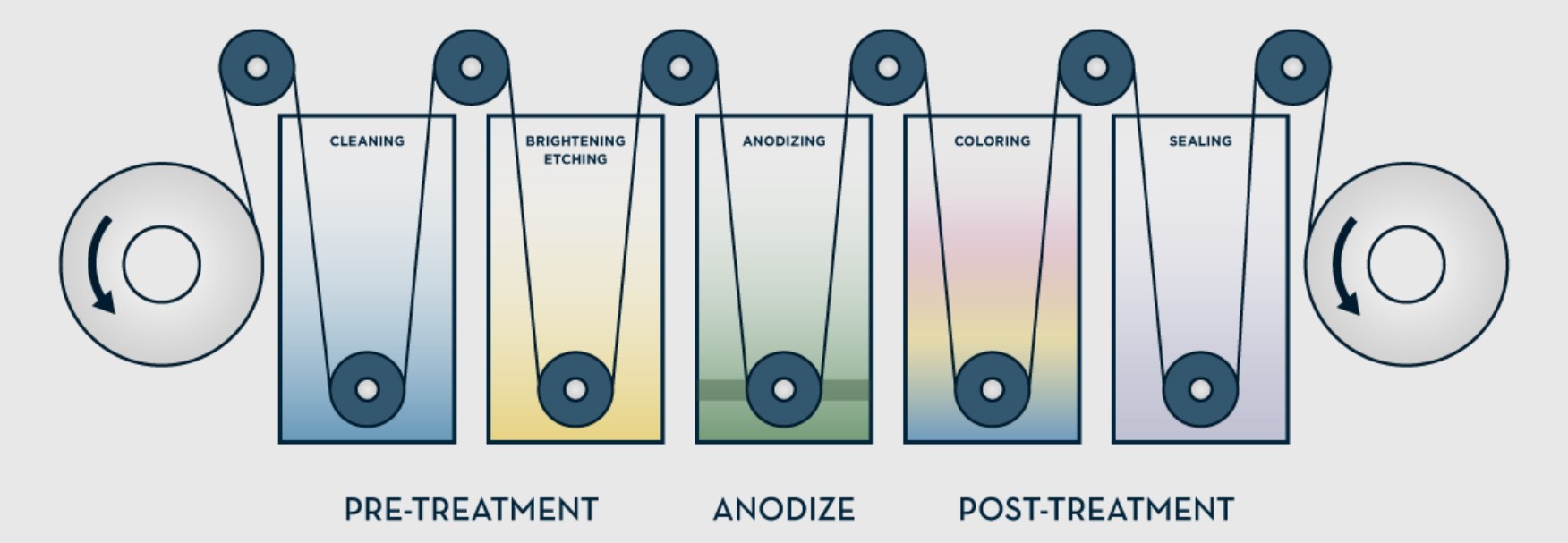

With one continuous process, the coiled raw aluminum is cleaned, brightened, etched, anodized, colored, sealed, and then rewound. This single, streamlined procedure both reduces scrap and lowers cost by placing the coils at the start and then allowing them to remain unhandled until the end of the process.

Long-Lasting, Authentic Appearance

The metal’s natural beauty shines through the clear, translucent oxide layer, achieving an authentic look that brings out the rich metallic appearance of aluminum. This translucent oxide layer of anodized aluminum is a crystalline structure that reflects and refracts light in a fashion that enlivens its color and allows its appearance to change alongside shifting light conditions.

Louisiana Caesar’s Superdome in New Orleans

Not only is the metal inherently corrosion resistant, but it creates vivid colors that do not chip, flake or peel, providing a long-lasting solution. The anodized aluminum retains its color, reflectivity and gloss for decades when UV-stable colors are used. Several colors can last upwards of 30 to 40 years.

A myth persists that anodized aluminum is offered in a limited set of colors, but anodized aluminum can actually come in myriad shades. It can be created to match the bespoke colors of specific requirements, such as individual brands, and it can also match the natural metal look of many metals, such as zinc, steel, titanium, copper, gold, brass and bronze.

Cutting Maintenance Costs

Coil anodized aluminum cuts maintenance costs in multiple areas. Due to its smooth and dense surface, and the fact that the oxide layer is dielectric so it resists static electricity, dust does not collect easily on surfaces. Anodized aluminum also has a hydrophobic surface that resists water and dirt build up. With cleaning required every other year, and no special chemicals needed, anodized aluminum enables considerable savings across the board.

Benefiting Health and the Environment

Coiled anodized aluminum does not emit volatile organic compounds (VOCs), which are harmful to human health. Anodized aluminum also helps to reduce the urban heat island effect by reflecting heat off the building. The lower heat load reduces the resource demand on HVAC systems, which cuts costs and lowers energy use over time, thus reducing the emissions that generally accompany energy production. Not only does the finished product provide environmental benefits, but the process behind it is also sustainable.

By investing in natural gas-powered power generation to replace energy from coal-fired power plants, Lorin has reduced the environmental impacts of its electrochemical process. The chemicals used in the process are reclaimed and recycled for reuse. With its own wastewater treatment plant, Lorin eliminates waste so that no additional treatment is needed before the water goes to the city’s water treatment facility.

Steven F. Soderberg is corporate marketing manager at Lorin Industries Inc., Muskegon, Mich. To learn more, visit www.lorin.com[1].

Continuous coil anodized aluminum process

- www.lorin.com: http://www.lorin.com/

Source URL: https://www.metalconstructionnews.com/articles/coil-anodized-aluminum/