Coil Coating Roundtable

by Jonathan McGaha | 4 September 2013 12:00 am

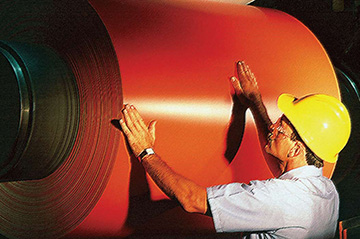

Coil coatings may not be something that the average general contractor or builder spends a lot of time thinking about. But they do have the ability to transform a building or a roof from dull to spectacular. And while you may not realize it, coatings are a constantly changing and evolving product. Metal Construction News asked industry experts to weigh in on the latest trends for this transformative product category.

Coil coatings may not be something that the average general contractor or builder spends a lot of time thinking about. But they do have the ability to transform a building or a roof from dull to spectacular. And while you may not realize it, coatings are a constantly changing and evolving product. Metal Construction News asked industry experts to weigh in on the latest trends for this transformative product category.

What new product developments will have the biggest impact on the industry?

Scott Moffatt, marketing director, coil and extrusion coatings, PPG Industries, Pittsburgh: Super-polyesters and silicon-modified polyesters have continued to improve, specifically in UV durability. Even though they are not anywhere equal to the performance of PVDF coatings, they offer a lower cost choice with moderate performance. Cool coatings are probably the fastest growing new technology in the market. The industry has converted completely to this technology, not only for roofing but also for wall panels. LEED points have accelerated this growth, even though they only pertain to energy savings for roof coatings.

Scott Moffatt, marketing director, coil and extrusion coatings, PPG Industries, Pittsburgh: Super-polyesters and silicon-modified polyesters have continued to improve, specifically in UV durability. Even though they are not anywhere equal to the performance of PVDF coatings, they offer a lower cost choice with moderate performance. Cool coatings are probably the fastest growing new technology in the market. The industry has converted completely to this technology, not only for roofing but also for wall panels. LEED points have accelerated this growth, even though they only pertain to energy savings for roof coatings.

Rob Roy, market development manager, Becker Specialty Corp., Elk Grove Village, Ill.: The paints that meet Energy Star certification for “cool roofing” continue to grow in the roofing/metal building industry and will continue. These coatings help reduce energy consumption/cost due to the roof/buildings being cooler. We will continue to see developments for “green” products and sustainability.

Rob Roy, market development manager, Becker Specialty Corp., Elk Grove Village, Ill.: The paints that meet Energy Star certification for “cool roofing” continue to grow in the roofing/metal building industry and will continue. These coatings help reduce energy consumption/cost due to the roof/buildings being cooler. We will continue to see developments for “green” products and sustainability.

Dan Happel, Western region sales manager, Metal Coaters, Houston: Alternative curing methods, super durable Polyester coatings that provide performance that is equal to or better than that of traditional SMPs, 100 percent solid coatings, pretreatment/primer combinations and DIP pretreatments that provide equivalent performance to traditional zinc phosphates.

Dan Happel, Western region sales manager, Metal Coaters, Houston: Alternative curing methods, super durable Polyester coatings that provide performance that is equal to or better than that of traditional SMPs, 100 percent solid coatings, pretreatment/primer combinations and DIP pretreatments that provide equivalent performance to traditional zinc phosphates.

Jeff Vellines, vice president, sales, Precoat Metals, St. Louis: Product development will continue to have a tremendous impact on the industry and play a growing role in the future. While new products and applications differ by market, Precoat has made a concerted effort to support the importance of this aspect of the industry with a dedicated new product development team. The sole objective of this team is to seek out, develop, and deliver collaborative solutions to our customers. Precoat’s product development team works in concert with the customer to first understand the intended application, benefits, and issue(s), which the new product can help solve or address. From there, new product specifications and processes are built from the ground up and follow a rigorous, but fast-paced trial and approval process to ensure that the product meets the exacting needs and requirements our customer is seeking and Precoat is passionate about delivering. Precoat’s expected investment in this area of our business continues to grow as more customers seek out coil-coated solutions as a path to making their business more successful, which makes having the right people and equipment available with the expertise to handle these needs a “must-have” in our business.

Jeff Vellines, vice president, sales, Precoat Metals, St. Louis: Product development will continue to have a tremendous impact on the industry and play a growing role in the future. While new products and applications differ by market, Precoat has made a concerted effort to support the importance of this aspect of the industry with a dedicated new product development team. The sole objective of this team is to seek out, develop, and deliver collaborative solutions to our customers. Precoat’s product development team works in concert with the customer to first understand the intended application, benefits, and issue(s), which the new product can help solve or address. From there, new product specifications and processes are built from the ground up and follow a rigorous, but fast-paced trial and approval process to ensure that the product meets the exacting needs and requirements our customer is seeking and Precoat is passionate about delivering. Precoat’s expected investment in this area of our business continues to grow as more customers seek out coil-coated solutions as a path to making their business more successful, which makes having the right people and equipment available with the expertise to handle these needs a “must-have” in our business.

Jeff Alexander, vice president of sales, The Valspar Corp., Minneapolis: At Valspar, we are committed to innovation and new product development. In addition to developing products that have improved weathering resistance, we are also focused on products with unique and distinguishing looks for many end-uses. The total elimination of heavy metals remains a major initiative. We expect this to remain a front-burner development as potential future environmental regulations could impact current product offerings.

Jeff Alexander, vice president of sales, The Valspar Corp., Minneapolis: At Valspar, we are committed to innovation and new product development. In addition to developing products that have improved weathering resistance, we are also focused on products with unique and distinguishing looks for many end-uses. The total elimination of heavy metals remains a major initiative. We expect this to remain a front-burner development as potential future environmental regulations could impact current product offerings.

What types of finishes are popular right now?

Alexander: Color is always an important aspect in selecting a finish; use of vibrant colors has become more popular as has print, metallic and textured effects coatings. Offerings of impeccable finish and endless color and design options are always popular, but durability and unique properties, such as energy-efficient coatings (SR), are increasing and becoming the norm when selecting a final color or finish.

Moffatt: Companies have tried to differentiate their standard product lines with a variety of special effects or niches. We have print coats and textured looks imitating asphalt shingles, but also specialty products like graffiti-resistant and antimicrobial coatings.

Happel: Texture finishes and textured low gloss finishes that provide the same anti-reflective appearance regardless of the angle from which it is observed. Polychromatic coatings and transparent topcoats that provide a pearlescent appearance are also popular.

Roy: In the building construction market, Siliconized Modified Polyesteters (SMP) and fluorocarbons are the most popular.

Vellines: We are always seeking to expand the decorative and functional possibilities we can achieve through the coil coating process to help our customers meet the needs of their business and their customer’s requirements. This may take the form of a coating that provides differentiating and interesting features, like “effects” coatings that change their appearance based on the viewing angle. Prints and film laminates can also be used to simulate another material, or to achieve a look that is entirely unique. As the range of finishes utilized by our customers increases, Precoat continues to invest in coil coating capabilities and processes that accommodate the broader range of finishes our customers are interested in. These investment decisions play a major role in our annual capital investment planning activities and manufacturing improvements we are striving to constantly make.

What is the most important thing the people on the construction site need to know about coil coatings?

Vellines: First and foremost is to wear the proper protective equipment and to handle the products safely.

There are a variety of tools available on the NCCA website (www.coilcoating.org) in the form of tutorials, videos, toolkits, case studies and frequently asked questions that address a range of topics of interest to prepainted metal users. In fact, Toolkit #1 (“Preventing Job Site Storage Corrosion of Prepainted Building Panels”) deals with a subject that is very relevant to the construction site.

In addition, Precoat has expertise and resources available at a moment’s notice to answer any questions regarding our coil coated products at the job site and has team members who have worked on these job-sites and understand best practices and can be available on-site to answer questions and support the process in any way or customers may need.

Roy: Even though coil coatings are very durable, they must try and reduce their exposure to moisture when sitting on the ground waiting to be installed. It is important to follow installation guidelines. Alexander: Steel panels often come packaged in plastic or paper wrap and may be exposed to the elements-rain, snow, sun-at the construction site. They may not always be stored according to recommended practices, and this is a common challenge that many people in the industry recognize. Water gets between the panels. The sun warms them up. This creates what amounts to an intense humidity cabinet, or what scientists call a hygrothermal stress. That stress can affect all components of the painted product including the substrate, pretreatment and paint. Proper handling is very important on a job site to help eliminate the wet field storage effect and avoid scratching of steel panels before they are installed on the structure.

Happel: That prepainted sheet is a finished product and need to be treated as such. All paint finishes can be scratched or marred so care must be taken on construction sites and all debris must be removed after installation.

Moffatt: During construction, there is always the possibility of damaging panels and scratching the surface of painted materials. Touch-up is available in the market for minor blemishes but these products are not the same quality as the original finish. Small scratches that have not been gouged down to metal are acceptable uses for standard touch-up materials, but large surfaces should be sanded, primed and coated with high-quality topcoats. If you are painting over a large area of a damaged PVDF-painted panel, then the construction site should use a fluoropolymer air-dry product that is close in quality to the original finish.

How is the coil coating industry meeting new environmental regulations and certification programs?

Roy: We continue to take out lead/heavy metals. We continue to reformulate coatings to meet RoHS

[Restriction of HazardousSubstances] and REACH requirements.

Moffatt: What comes to mind first is the rise of CRRC [Cool Roof Rating Council], Energy Star, LEEDv4 and the Living Building programs. Many of the tests involve three years of exposure testing. Color families have helped streamline this process, but new and unique coatings have a waiting period to bring innovation to the market.

Vellines: The importance of sustainability is becoming more critical. Although the coil coating process is quite carbon and energy friendly, we work with other organizations to demonstrate this performance level as well as improve along the way.

Precoat focuses on staying up to speed on any aspects involving environmental regulations involving not only our direct industry, but any regulations or trends involving our customers and their supply chain which may be downstream. Communicating these trends to our customers and determining a collaborative course of action to address the issue helps to ensure that our product offerings stay ahead of the curve in meeting any environmental regulations or certifications, which materially impact our customer base.

Alexander: We take our responsibility to the environment very seriously, developing innovative products that meet or exceed the regulations and certifications that are important to our customers.

Today, nearly all of Valspar’s coatings are formulated to meet Energy Star and LEED requirements. The new LEED v4 requirements, requiring increased SR and SRI values, will have a significant impact on what colors will meet the new requirements and will affect how buildings look in the future.

Our technical and product stewardship experts are continually looking for new opportunities to meet this new challenge; working with suppliers, conducting our own research to meet the latest requirements and reformulating our coatings. Conflict-free minerals are another important topic in the industry. While this initiative is relatively new to our industry, total compliance is expected.

What are the major regulatory challenges the coil coating industry faces?

Alexander: The coil coatings industry has long embraced the green revolution. There are real environmental and cost benefits to make sure our coatings meet all regulatory challenges. Two of the major regulatory challenges we are facing are the elimination of chrome and heavy metals. The REACH and RoHS regulations are the most prominent. The challenge with the removal of chrome is that it could impact adhesion and the overall performance of the coating.

Roy: We believe going chrome free is the biggest challenge. Chrome-free coatings do not weather as well as coatings that contain chrome and are run on chrome containing pretreatments. We continue to receive requests to look at going chrome free but when weathering results are discussed and shown they usually prefer the chrome.

Moffatt: There are a lot of new green regulations that are changing the reporting of coil-coated paint systems. The new LEEDv4 with higher SRI requirements and The Living Building Challenge that includes a red list of unacceptable raw materials are asking paint companies to divulge paint formulations by listing raw materials. These paint formulas are considered proprietary so there is a lot of reluctance to pass on this information. Certain buildings may not have paint specified for these reasons.

Happel: The European Union has banned Hexavalent Chrome from products effective Jan. 1, 2016. Most expect U.S. federal or state legislation to follow suit. Hexavalent chrome free pre-treatments have gained market acceptance. Hexavalent Chrome free primers are in the process of being developed and/or trialed in the U.S.

Vellines: Precoat’s ongoing focus in this area is to develop alternatives that don’t compromise product performance or features that our customers value, but proactively find these alternatives before regulatory issues dictate a change and which do not pose any regulatory concerns for our customers.

A major challenge currently is heavy metals, including strontium chromate. Europe is on the verge of banning strontium chromate. Other chromates, such as lead chromate, already have sunset dates (May 2015). It is anticipated that the U.S. may not be too far behind, so besides monitoring activities in Europe the pretreatment, paint and pigment suppliers are all working with coaters to find acceptable performance alternatives. Other heavy metal pigments (lead and cadmium) are being regulated out and alternatives are being evaluated to ensure acceptable long-term performance (weathering), especially for bright/deep colors.

From a business point of view, how has the coil coating industry changed over the last five years?

Alexander: It is important to recognize that change has come on many levels. Locally, we’ve seen major consolidation among the coil coaters and consolidation within the metal building and component manufacturers. From a global perspective, the [North American] paint companies are expected to have supply capabilities to all regions of the world. Five to 10 years ago this was not the case. The demand for environmentally friendly products was minimal five years ago. Today, it’s a major focus of our industry. The overall supply chain has changed within the last five years. Today we face a strong threat from low-cost pre-painted imports. This is of a concern, not only from a market share standpoint, but concerns that these imports may not meet the performance criteria that end user customers expect.

Happel: Over the last six years, the coil coating industry has changed dramatically through consolidations and the implementation of new technologies.

[Luxembourg-based] Ternium sold most of its U.S. coil coating assets to BlueScope Steel [Melbourne, Victoria, Australia]. BlueScope’s U.S. coil coating and rollforming assets subsequently entered into a joint venture with [Tokyo-based] Nippon Steel. In 2007, SDI [Steel Dynamics Inc., Pittsboro, Ind.] opened another paint line. Precoat [Metals, St. Louis] acquired Roll Coater [Inc., Indianapolis] in 2011, and the combined entity has greater than 40 percent of the U.S. market. Metal Coaters acquired, refurbished and reopened the former MSC [Material Science Corp., Elk Grove Village, Ill.] coil coating line in Middletown, Ohio. PPG [Industries, Pittsburgh] acquired BASF [Florham Park, N.J.] and Becker

[Industrial Coatings, Elk Grove Village] acquired Specialty

[Coatings Co. Inc.]. Yung Chi or Rainbow Coatings [Kaohsiung, Taiwan] opened up a domestic coating manufacturing subsidiary, and other Asian coating manufacturers are looking to enter this market.

Dried in Place (DIP) chrome free pre-treatments that are RoHS and REACH compliant have captured significant market share and have become readily accepted in many applications. Research in new or alternative pretreatment technologies has greatly accelerated.

Roy: With the recession and the fluctuation of steel prices, most customers have gone to Just in Time (JIT) programs. Service centers and end customers are carrying less inventory. They do not want to get stuck with high priced inventory. This has put pressure on the whole supply chain to deliver quicker. Lead times are shorter. This is the new model.

Moffatt: The economic downturn over the last five years has initiated more cost-cutting initiatives but very little change over this period. We have seen more Asian imports, especially on the West Coast, that have cut American suppliers out of lower cost markets. There has also been the addition of a couple new coil coaters and aluminum composite manufacturers into the mix.

Vellines: The pace of change has accelerated dramatically.

As a coil coater, it is critical for Precoat Metals to provide solutions and flexible options that allow customers to take advantage all of the aesthetic and/or functional features and benefits available within our portfolio of products.

It is vital to make sure our valued customers are aware that all of the products and accompanying service requirements can be customized to meet individual needs and specifications. This level of flexibility makes constant collaboration, customer service and technical support that is valued critical to dealing with the incredible pace of change we are seeing in the marketplace today. All of our people, processes and manufacturing assets must be aligned around being easy to do business with to ensure we are meeting and exceeding the needs of our customers in every way.

What does the future hold for the coil coatings industry?

Roy: The coil coatings industry will continue to grow, but a little more slowly over the next couple of years. There are still a lot of growth opportunities in the residential metal roofing market.

Vellines: The future is extremely bright for the coil coating industry! As the rate of change and degree of complexity increases, Precoat is focused on building on new ways to deliver on a single objective-understanding the individual needs and requirements of our cherished customers and delivering on those requirements in a way that delights our customers and leads to their business growing and becoming more successful.

Happel: Further consolidation and growth as demand for residential and nonresidential construction recovers.

Moffatt: Green movements will continue to push for more environmentally friendly coating systems and products that conserve energy. Since buildings utilize 40 percent of the world’s energy requirements there will be continued pressure to improve metal building products. If energy costs ever rise and stay at heightened levels, you will see more requirements for alternative-cure products like low-cure systems, UV and EB curing methods.

Alexander: Beyond the recurring issues related to environmental regulation, threat from prepainted imports, reduction in heavy metals and an introduction of the new substrate magnesium zinc and other new substrates. We have seen demand for pre-painted material increase, as the economy recovers and commercial construction returns.

New opportunities to convert post-paint applications into pre-painted applications will continue to grow locally and globally in all market segments.

The entire industry will see more consolidation; from paint companies, coil coaters, service centers and end users. Managing of raw materials sourcing will also affect the coatings supply and cost, causing capacity fluctuations.

Source URL: https://www.metalconstructionnews.com/articles/coil-coating-roundtable/