Coil Coating Technology Evolution

by Jonathan McGaha | 30 September 2015 12:00 am

Coil coating processing technology produces high-quality prepainted metal with minimal environmental impact

The evolution of advanced continuous coil coating technology has been tremendous since its introduction to the market over 50 years ago. Coil coating technology not only produces high-quality finished goods, but also enables a process that is cost-effective, efficient and eco-friendly.

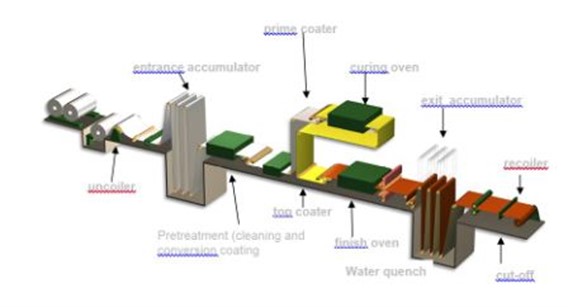

Coil coating is a continuous and highly automated process for coating metal prior to fabrication of the desired part like metal building panels. In one continuous process⎯a coil of metal, up to 72 inches wide moving up to 700 feet per minute⎯is unwound, and both the top and bottom sides are cleaned, chemically pretreated, primed, oven cured, top coated, oven cured again, rewound and packaged for shipment.

Processing Technology

More specifically, bare coils of metal are placed on an unwinder

(also known as a decoiler) where the metal is inspected and fed into the continuous coating line. The metal is then chemically cleaned to remove oil and other surface contaminants. Brushes can be used to physically remove contaminants from the sheet, or the metal may be abraded by flap sanders or brushes to further enhance the surface.

Chemical pretreatments are then applied to improve corrosion resistance and to enhance adhesion of the organic coatings to the pretreated metal substrate providing the bond between the metal and the coating. The type of chemical treatment varies with the substrate, but all common metals in coil form may be pretreated and processed on a modern coil line.

After drying the pretreatment, the strip enters a coating room for a coat of primer, usually applied on both sides of the sheet by a series of roller applicators. The painted substrate (strip) then enters an oven to be cured. Dwell time in the oven depends on the paint specifications and the thickness of the substrate. A typical dwell time would be 15 to 30 seconds. The strip exits the oven and is quenched with air and water to cool the surface. Specifications may call for another coat of paint, requiring a pass through a second coater room where the topcoat is applied on one side of the strip and a backer is simultaneously applied to the other side.

The coated strip then passes through another oven to cure the topcoat. The painted sheet exits the second oven, and is cooled before inspection and rewind. During the inspection process, the physical properties of the coated metal are carefully assessed for hardness, flexibility and adhesion, and the aesthetic properties-color and gloss-are measured using state-of-the-art devices to make certain these two properties fall within the tight tolerances that guarantee coil-to-coil consistency.

|

| Photo courtesy of NCCA |

Efficiency and Control

Since the process allows metals to be finished in one continuous pass, the coil coating process is inherently efficient. In addition to this process efficiency, there are a wide variety of coatings that may be applied on a coil line, such as polyesters, epoxies, vinyls, plastisols, acrylics, water-born emulsions, fluorocarbons and dry lubricants.

Prepainted coils can also be printed, striped and embossed to create special visual effects. Because a continuous flat strip is processed on a coil coating line, it is easier to control the various processes, such as mechanical brushing, chemical cleaning and pretreatment, and the application of the organic coatings. Such advantages, along with the economic and environmental benefits, make coil coating the right choice for many manufacturers.

Prepainted metal can be formed and shaped to make the most demanding parts. Prepainted metal can be rollformed or stamped to make panels used in construction, home appliance doors and bodies, HVAC louvered tops, metal shingles for residential roofing, just to name a few. Prepainted metal can be joined easily⎯using adhesives, fasteners, or welding⎯and still retain a beautiful and flawless surface.

Higher Quality

The coil coating industry is constantly evolving to produce higher quality products with a lower environmental impact. Today’s coil coating lines capture the volatile organic content (VOC) originating from the solvents in the paints, and destroy these VOCs in a thermal oxidizer. Not only does this eliminate any VOC from exiting the coil coating facility, but the heat generated in the process is directed back into the coil coating facility and is used as a heat source, thus reducing the need for other forms of energy.

No-rinse pretreatments are commonly used, and their use reduces water consumption and waste, while minimizing energy consumption. Typical coil coating curing ovens are fueled by natural gas, but other kinds of ovens are perfectly suited for the coil coating process, such as induction cure, infrared and near-infrared cure.

Laura Lanza is marketing committee chair for the National Coil Coating Association (NCCA), Cleveland. NCCA’s website, www.coilcoating.org[1], has information regarding coil coating in the form of tutorials, videos, toolkits, case studies and frequently asked questions about the coil coating process, benefits of prepaint and the industry.

- www.coilcoating.org: http://www.coilcoating.org

Source URL: https://www.metalconstructionnews.com/articles/coil-coating-technology-evolution/