Combustibility and Building Insulation

by Mark Robins | 1 November 2021 12:00 am

An increased awareness of building fires has increased building insulation combustibility awareness

Insulation material is being tested via ASTM-E84 in a Steiner tunnel. (Photo courtesy of Silvercote)

One building component that has received attention for its combustibility is insulation. Building insulation conserves energy, but can also be a fire risk. There are many types of insulation material, and each has its own degree of combustibility.

Why is insulation combustibility an important issue? “With ever-increasing energy codes requiring more insulation or more efficient types of insulation to be used in construction, insulation can also increase the risk of fire spread and/or smoke and toxic gases depending on the materials being used,” says Mike Smith, technical manager, Silvercote LLC[1], Greenville, S.C.

“Insulation contributes to the flame spread of the wall assembly and it also happens in a concealed area, so you never know how far it really spreads until another fire pops somewhere else,” cautions Andy Williams, PE, director of codes and standards at Metal Construction Association[2].

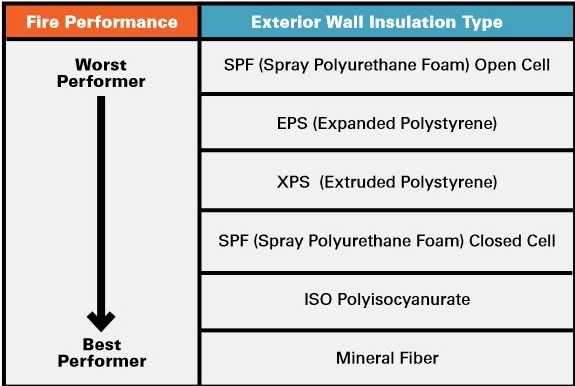

This chart shows how fire performance varies by insulation type. Refer to individual manufacturers for specific performance information. (Chart courtesy of Metal Composite Material Alliance)

Jonathan Humble, FAIA, NCARB, LEED BD+C, regional director at American Iron and Steel Institute[3], explains insulation combustibility is important for several reasons, such as, “Limiting the exposure to fires and allowing the insulation to produce additional fuel load through flame spread and smoke, which are hazardous to occupants of buildings.”

Overall, Catherine Knight, architect, LEED AP BD+C, O+M, CDT, A M King[4], Greenville, S.C., stresses knowing the importance of what materials and products you are using in the assembly of your building. “Are they suitable for the goals you’ve set out to accomplish with insulating the space? Are they part of a UL-rated assembly and need to meet a fire-resistance rating based on the building occupancy or proximity to another building? Be familiar with the products you are specifying and what substitutions you may be able to accept. The Grenfell Tower fire in London is a perfect example of the importance of understanding the products being installed on a building and making sure in the event of an emergency they perform to limit the spread of fire and not encourage it.”

Combustibility Consensus, Concerns, Codes

What is combustibility? An online dictionary defines it as “capable of catching fire and burning; flammable.” Is there an industry-accepted rating scale to determine insulation combustibility? “At this point in time there’s no industry consensus for any rating scale, nor do I see one happening,” Williams says.

David Mann, senior director, North American Modern Building Alliance[5], says to be acceptable for building use, “Insulation materials must meet the prescriptive and performance-related provisions of the applicable building codes.

However, in the International Building Code, there is no specific definition for the term: combustible. A material is either combustible or non-combustible; however, common terms in the construction industry are non-combustible, combustible, fire resistant and ignition resistant. These terms can refer to individual material characteristics or assemblies.”

“There are different tests associated with each of these terms,” Smith says. “Most common for determining combustibility is ASTM E-136. In our industry, our materials are designed to be left exposed, and are typically tested under ASTM E-84, which looks at a material’s flame spread and developed smoke when compared to a control substance. Materials can receive a fire rating of Class A, B or C, depending on how quickly the flame moves across the sample and how much is smolders when exposed to an ignition source over a 10-minute test period. Most architectural specifications will require the strictest Class A rating of 25/50, which qualifies material to be left exposed in a plenum application. The 25/50 means the material must produce a flame spread rating of at most 25% and smolder at 50% or less than that of the control material.”

Exterior EIFS insulation.

(Photo courtesy of A M King)

According to Humble, the 2021 edition of the International Building Code does have applicable requirements. “Section 720.7 Thermal and Sound-Insulating Materials requires insulations to be tested in accordance with ASTM E84 for determining flame spread index and smoke development index. Further requirements usually limit the flame spread and smoke development indexes to 25 and 450 respectively. Notice this is not a combustibility requirement per se.

Combustible or non-combustible products or materials—notice I did not say insulation—are defined as follows: Section 703.3.1 where it states: ‘Materials required to be noncombustible shall be tested in accordance with ASTM E136 Standard Test Method for Behavior of Materials in a Vertical Tube Furnace at 750 C.’ The only insulations that can comply with this are mineral wool and glass fiber insulations as they are mineral-based products. All other insulations are considered combustible.”

National Fire Protection Association[6]’s NFPA 101 Life Safety Code gives a building environment specific definition for combustibility, which states: “A material that, in the form in which is it used and under the conditions anticipated, will not ignite and burn; a material that does not meet the definition of noncombustible or limited-combustible.”

While the definition of insulation combustibility may be nebulous, Knight cites several industry tests to confirm combustibility:

• ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials

• FM 4880, Class 1 Fire Rating of Insulated Wall or Wall and Roof/Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems

• NFPA 286, Standard Methods of Fire Tests for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth

• UL 1040, Fire Test of Insulated Wall Construction

Different Insulation Materials’ Combustibility

What types of insulation are most combustible? What types of insulation are least combustible?

Humble says these questions require several qualifiers to address and understand the complexity of the title combustible in context of the national model codes. He explains in the International Building Code insulations include the following categories:

• Ceramic fiber blankets (Normally mineral wool insulations)

• Continuous insulation (Normally plastic insulations and mineral wool insulations)

• Exterior insulation and finish systems (Plastic insulations as part of an exterior wall assembly)

• Foam plastic Insulation (foam boards, spray foam)

• Glass fiberboard (glass fibers formed into board, roof applications)

• Mineral board (mineral fiber)

• Loose fill (cellulose, plastic foam, etc.)

Association information is a reliable source for fire safety and material combustibility. (Image courtesy of North American Modern Building Alliance)

Furthermore, Humble says the code requirements also have different requirements and limitations for insulations for the following conditions:

• Installed in a wall or building envelope cavity (concealed or encased), or on the exterior face of the wall

• Installed on the roof

• Installed around piping, HVAC ducts, etc.

• Installed to address acoustics in walls and ceiling/floor assemblies

• Installed in attics

• Installed onto foundations (e.g., underground)

Mann concurs that fire test standards differ by application and condition, and that building codes mandate the fire performance of assemblies and products, including insulation. “For example, fire tests for roofs are different than fire tests for exterior walls. So, it is not a question of which insulation is most combustible, but which insulation meets the code requirements for a particular application. The least, or in some cases, noncombustible type is mineral wool, which is basically glass slag.”

Despite these qualifiers, there still are differences in different insulation materials’ combustibility. “The most combustible types of insulation are in the foam type category,” Williams says. “The nature of foam insulation is based on chemicals, which will always be combustible. Depending on how they tweak their balance between them is a real trick even to meet their flame spread and smoke-developed ASTM numbers.”

Smith says there are three main types of insulation: fiberglass and rock wool, foam and cellulose. “Cellulose is mostly made up of newspaper and is not considered non-combustible. It must have a warning label despite being fire resistant due to the required fire retardants. Fiberglass and rock wool are considered noncombustible and do not have any fire retardants added to them. Unfaced glass and mineral wool are commonly used as fire blocks and in wall assemblies to meet fire ratings. Some of the Kraft and foil facings are considered combustible and shouldn’t be left exposed. The vapor retarders’ facings used in the metal building industry are rated for exposed use. Spray foam ignites at 700 F.”

Knight says fiberglass and mineral wool are typically noted in UL fire-rated assemblies and make up some of the most common insulation used in the design and construction field. While these insulation types are made from materials that have fireproof properties, she explains that these materials must have a backing of foil or paper, or they are not as flame resistant.

“Typically, polystyrene and Styrofoam (packing materials, egg cartons, take-out containers) do not have fire-proofing additives and are the most combustible insulation materials. Polystyrene and Styrofoam used for building products are treated with fire-proofing materials and are not the exposed finish material on the interior or exterior of buildings. These types of insulation are found covered by a finish material as part of a wall system. An example would be exterior insulation and finish system (EIFS). These insulation types are often used as continuous insulation—creating a continuous barrier around the exterior of a building to meet energy code requirements.”

Mann explains that because all plastics, including foam plastic insulation, are combustible, building and fire codes place strict fire performance criteria on these materials and their uses in building applications.

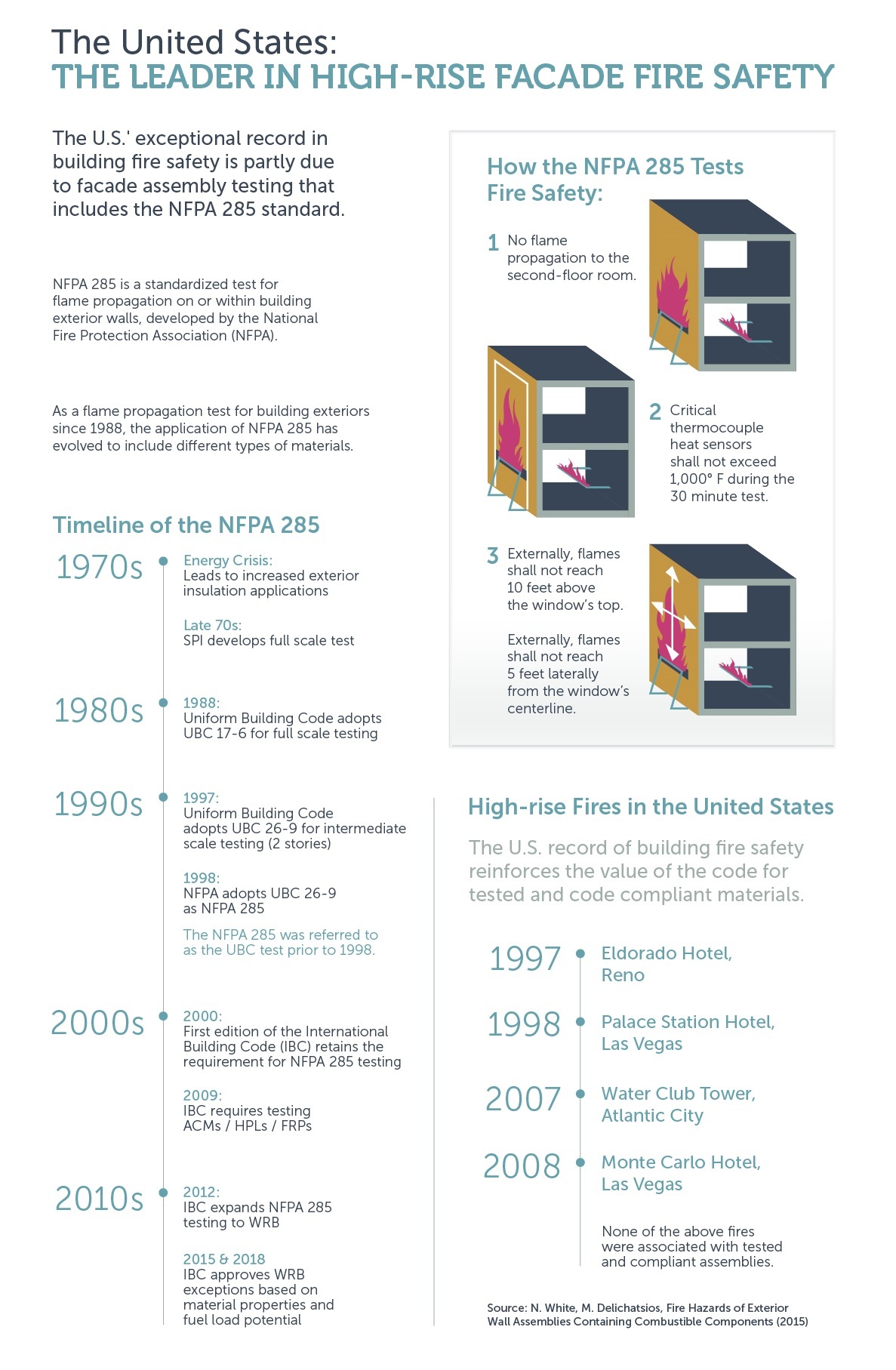

“Manufacturers often use flame retardants in finished products to help meet the stringent building code fire performance criteria for flame and smoke spread indices and assembly tests such as NFPA 285. NFPA 285 is the Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

Fire science experts recognize that the use of flame retardants help to delay fires from starting and to slow their spread, both of which are crucially important when every second counts.”

Knight says there are new options for insulation such as denim, cork and wool. “There are strategies for addressing energy efficiency and combustibility with recycled or natural products.”

Regarding fire retardants and insulation combustibility, Smith says fire retardants are added to raise the ignition temperature or help the material to self-extinguish. “Though fire retardants will not make a material noncombustible, they can certainly raise a material’s fire rating.”

Regarding plastics and their combustibility, Humble recommends reading Chapter 26, Plastic, in the International Building Code. “This chapter contains the necessary requirements about the application of plastics and foam plastics in building envelope assemblies. The chapter contains the necessary tests required to demonstrate compliance for fire performance characteristics.”

Overall, building fire safety does not depend solely on whether a particular insulation material is combustible or noncombustible. “Fire safety reflects a robust multilayered approach developed and enforced through building and fire codes that supports prevention through design, construction and maintenance, as well as detection, occupant protection and evacuation, containment and extinguishment,” Mann says

Exterior EIFS insulation.

(Photo courtesy of A M King)

- Silvercote LLC: https://www.silvercote.com/

- Metal Construction Association: https://www.metalconstruction.org/

- American Iron and Steel Institute: https://www.steel.org

- A M King: https://amkinggroup.com/

- North American Modern Building Alliance: http://www.modernbuildingalliance.us

- National Fire Protection Association: http://www.nfpa.org/

Source URL: https://www.metalconstructionnews.com/articles/combustibility-and-building-insulation/