Condensation Control with Detailing

by Mark Robins | 1 March 2022 12:00 am

Detailing a metal building’s thermal envelope controls temperatures, and protects buildings and their occupants

Condensation on a metal panel. (Photo: Gratuit, courtesy of www.freeimages.co.uk)

“The entire envelope of the building should be weathertight,” says Derrick Chambers, technical manager and quality engineer at Fi-Foil Co. Inc.[1], Auburndale, Fla. “This is the first line of defense to keep humidity out of the building.”

Controlling condensation because of moisture (in the form of water vapor in the air) is important to protect building occupants from adverse health effects. Also, condensation can cause immediate- and long-term building damage, create critical dampness problems and negatively impact building temperature. Condensation is most likely to occur on the inside of exterior walls or roof assemblies, and when there is a high level of humidity inside a building.

Condensation must be prevented from entering buildings and compromising its integrity, especially its insulation. Insulation helps prevent unwanted heat loss (or gain) in structures. But, once condensation dampens insulation, it can stay damp and lose its R-value. Also, moisture and water trapped between insulation and the exterior of a building can cause mold, fungus growth, rust and oxidation.

Compromised Continuity

Key to controlling condensation is ensuring the building envelope does not drop below the dew point temperature. Correct detailing of moisture barriers and insulation (in addition to automated humidity control and ventilation) is one way to do this. Detailing reduces heat loss and keeps internal temperatures within the optimum temperature necessary to avoid condensation. If there is a hole in an air barrier and the building is under negative pressure at that location, cold infiltrating air may bypass the insulation layer and chill indoor surfaces to temperatures below the dew point. During warm weather, detailing helps prevent leakage of outdoor air into the exterior enclosure or interior wall, ceiling and floor cavities.

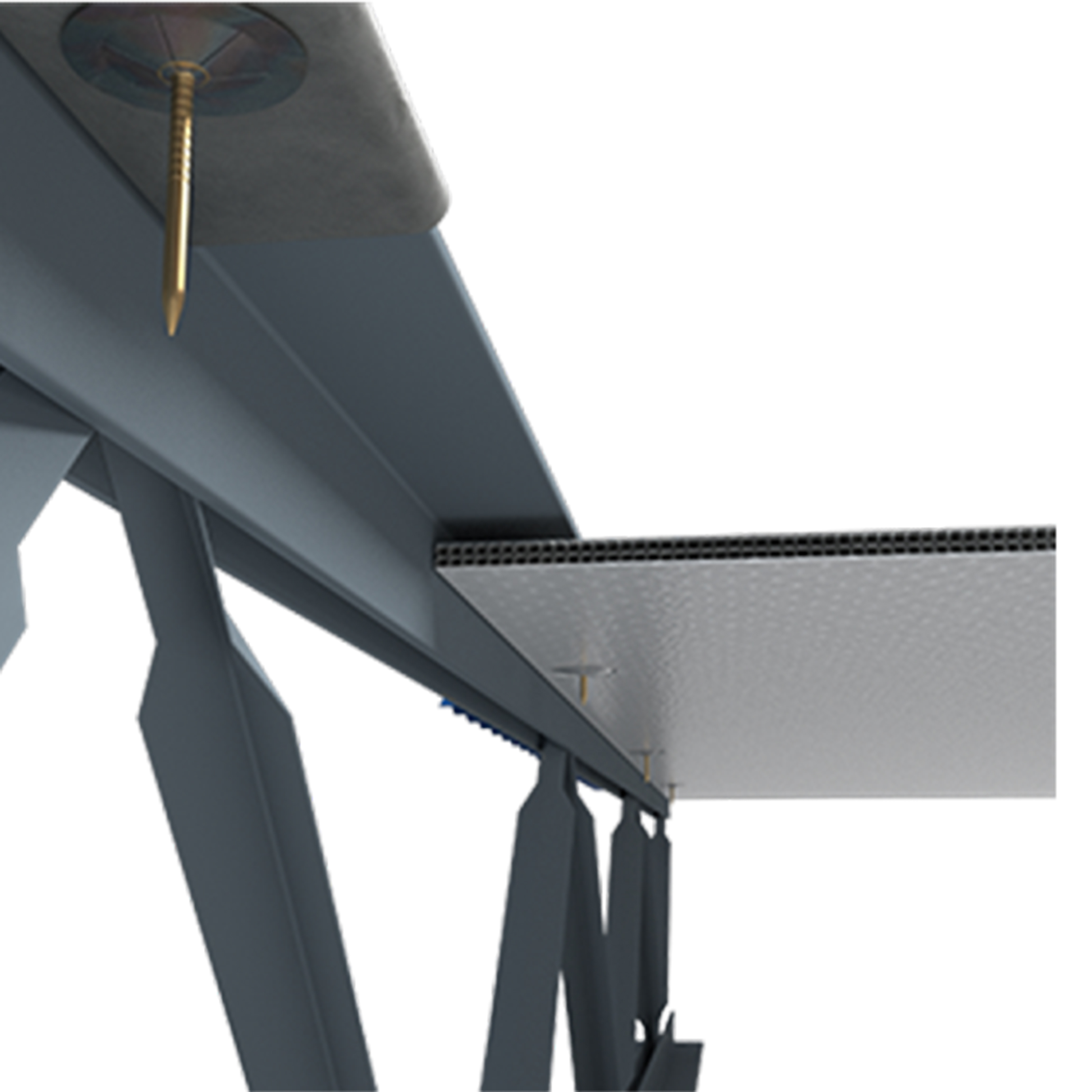

Example of detailing to reduce condensation. (Image courtesy of Fi-Foil Co. Inc.)

Example of detailing to reduce condensation. (Image courtesy of Fi-Foil Co. Inc.)

Improperly installed insulation or vapor barriers can result in holes and penetrations. All holes and penetrations, as well as air gaps, voids, cavities, thin areas and seams should be detailed; they create an opportunity for moisture migration. Also, air barrier continuity can also be compromised between conditioned and unconditioned building spaces because of plumbing stacks, wiring, ductwork, electrical outlets, windows, doors, pipes, shafts, sill plates, top plates and conduits.

Detailing methods aid continuity at penetrations, as well as at corners and edges. Heavy steel construction must be carefully detailed where the exterior walls meet vertical steel posts or horizontal beams, locations where the air barrier must pass around structural elements. “The detailing for condensation prevention is unique for metal buildings because of the increased probability of heat transfer due to the thermal conductivity of metal,” says Chambers.

Detailing

Warm air will always find the path of least resistance. “Warm air has moisture content, and once within the roof or wall cavity, will find the dew point temperature in northern climates during the colder months,” says Bill Beals, district manager, Therm-All Inc[3]., Westlake, Ohio. “Fiberglass must be packed tightly around all penetrations to minimize any air space within the cavities. Any open air spaced around penetrations, corners and edges allows moisture to condense very fast and begins the process of liquid water dripping around and within that area.”

“Cut metal building insulation material to fit snugly around penetrations and seal all joints using an appropriate sealant such as PET tape or other quality sealant compatible with the material,” advises Sherri Riccio Diaz, director of marketing and eCommerce, Fi-Foil. “Using a flexible insulation material is ideal when there are several penetrations; one designed with an integrated tape edge will allow sealing the sheets easily to create an effective vapor barrier. In all cases, where material meets, install an overlap per manufacturer’s installation instructions.”

Tom Olver, district manager at Therm-All, Sparrow Bush, N.Y., explains additional backup angles at corners and roof/wall transitions are a great way to provide a positive termination point for facing intersections. “Granted, these materials are an additional cost for both material and labor, however they go the extra mile in assuring a complete seal.”

CondenStop is an absorbent material that minimizes condensation on metal panels by absorbing the moisture that accumulates on them. (Photo courtesy of Midwest Steel Carports)

Rick Bachman, district manager, Therm-All, Phoenix, explains corner insulation needs to have extra attention to ensure there are no gaps in the insulation. “The vapor barrier must stay completely up the entire vertical edge. [Also,] when trimming for any opening, cut an “X” into the insulation slightly smaller than the opening. Remove the insulation from the flaps and tuck the left-over vapor barrier behind the remaining insulation.”

Francis “JR” Babineau, research manager/building scientist at Johns Manville[2], Littleton, Colo., agrees that insulation should always be cut to fit snugly around any penetrations or other features, without being overly compressed. “Vapor/moisture retarders should also be detailed, but the more important issue with these layers is that they must be detailed and sealed to reduce air leakage. Air leakage is by far the largest source of condensation; much more than water vapor diffusion.”

Insulation application details often vary depending on the type of insulation being used on the structure. “In instances when dealing with roll-on applications, such as fiberglass (with paper backing) or radiant barrier, the layers should be overlapped to create continuous layer of insulation,” says Lizett Aguilar, marketing director, Midwest Steel Carports[4], Grant, Mich. “The seam should be taped to eliminate any openings or gaps in the insulation, which will in turn create a better seal. This is installed between the framing and the sheeting of the building to help create a tighter seal when overlapping said insulation layers. In instances when dealing with a spray foam insulation, you must ensure the application near these areas (corners, edges, etc.) are adequately covered to create a tight seal. Spray foam is typically applied directly onto the interior surface of the structure. Once applied, the foam will expand to varying levels of thickness, making it easier to reach smaller hard-to-reach areas. Applications with spray foam insulation are unique to metal structures and it is highly recommended to use the closed-cell foam. Open-cell foam can cause shifting of the framing and steel panels and damage the building’s structural stability.”

To avoid moisture migration, vapor barrier installation on metal beams should be done without holes, gaps and penetrations. (Photo courtesy of Fi-Foil Co. Inc.)

Chambers says the detailing differences for residential versus commercial buildings will be based on the code requirements for each and that different types of buildings are regulated by different codes. “Installing code-approved insulations for your climate zone ensures the building envelope is insulated to a standard that will reduce or mitigate moisture when all products are installed properly.”

Babineau explains that while detailing is very similar in residential and commercial buildings the differences appear based on how the buildings get built. “Commercial buildings can present unique challenges, especially when they include features like balloon-framed parapets or large features such as a porte cochere or other elements that might have structural steel extending out from the building envelope.”

Windows, Doors, Components

Windows and doors are relatively simple for detailing in metal buildings. Most of these areas have the vapor barrier terminated into the sub-frames that surround these penetrations. “Some will extend the vapor barrier into the framed opening to assist in airtightness,” Beals says. “Electrical boxes and conduits are not specifically detailed by the insulation supplier. We rely on the contractors responsible for these areas to seal any hole they create.”

Metal jacketing is one method to control condensation. (Photo courtesy of Johns Manville)

Structural components have evolved over the years and have become standard details for liner insulation systems. “Specifically flange bracing, corners and roof-to-wall transitions are all shown and detailed in insulation system drawings used in each project,” Beals says. “We also include suggested fasteners that will penetrate the vapor barriers to minimize any holes that could be created with old methods when secondary framing members are not exposed.”

There is no identical condensation-prevention formula for every building. Specific considerations should be given before construction to design, assemble and detail building components to prevent condensation within roofs and walls. Bachman says insulation and vapor barrier detailing for metal buildings is, “Unique, as it is part of the structure instead of being added after the structure is built.”

Olver stresses training and installation instruction are critical to a satisfactory detailing job. “Many times, installers are unaware of the instructions. We often provide on-site training and kick-off meetings [with them] to ensure accurate installation and detailing.”

This grocery store with bar joists uses a long-tab-banded insulation system. (Photo courtesy of Therm-All Inc.)

- Fi-Foil Co. Inc.: http://www.fifoil.com

- Johns Manville: https://www.jm.com/

- Therm-All Inc: http://www.therm-all.com

- Midwest Steel Carports: http://www.mwsteelbuildings.com

Source URL: https://www.metalconstructionnews.com/articles/condensation-control-with-detailing/