Expanded Metal Ceiling Panels: Practical, Versatile, and Decorative

by David Flaherty | 18 August 2025 6:28 pm

[1]

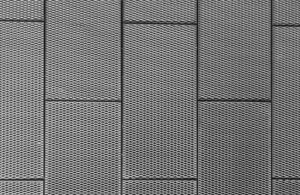

[1]Construction and architectural professionals prefer materials that are strong, lightweight, and easy to work with. Expanded metal has experienced a resurgence in popularity due to its versatility. It’s often chosen for its uniform pattern and strength-to-weight properties, making it an excellent choice for ceiling panel systems for small or large-scale projects.

Preinstallation: How to specify for project success

A good starting point is asking, “What do you want your ceiling panels to accomplish?” Larger openings provide a sense of openness, whereas smaller ones conceal substructure elements. Partnering with an expanded metal manufacturer will provide valuable insights and recommendations for project success. Key dimensions must be calculated before manufacturing to ensure the expanded metal ceiling panels meet specifications. These include open area percentage, weight, strand width and pitch, the long way, and short way openings, and the sheet length and width. The raw metal thickness and whether the expanded metal will be flattened must also be considered. Flattened expanded metal will allow direct views of the ceiling substructure, whereas if the strands are left raised, they will be obscured by limiting lines of sight. Manufactured from a metal coil, it is fed into an expander that slits and simultaneously stretches it, and is then cut to the specified length. This produces a strong, lightweight panel with no strands that can unravel and a diamond-shaped signature pattern. Steel and aluminum are the two most selected metals, with copper chosen for its striking appearance. Not limited to a square or rectangle, the ceiling panels can be cut and formed into shapes for a unique design. This will require customized frames to accommodate the different shapes.

[2]

[2]Optional post-production applications, such as paint or powder coat, can be applied to enhance aesthetics and extend the lifecycle. If planning to add a coating, an important rule to follow is to expand first and to coat second. Metal that is first painted and then expanded will produce unpainted edges where the metal is slit. In addition, manufacturing expanded metal sheets after the powder coat is applied will also crack the coating, compromising its protective finish. Although paint can be used on the job site, it is recommended to be applied after the metal is expanded to facilitate the installation process.

When deciding how the panels are to be installed, it is critical to consider their placement relative to the fire sprinkler system. It is recommended that sprinklers be installed below the panels; however, fire codes mandate that the openings must meet a minimum size or open area percentage if the panels are positioned below the sprinklers. This ensures sufficient water can be dispersed from the sprinklers when activated.

Installation and options

For a relatively simplified installation, expanded metal ceiling panels can use the same regular dropped ceiling grid used for acoustic tiles. Cut to size and coated if needed at the manufacturing plant, they are placed into the grid and attached. Another option is to form the expanded metal sheets with edges that run along their length. The panels are fastened to parallel rails to hang below the frame and are set edge-to-edge. This results in panels with a seamless pattern, concealing the frame above. This installation may also include dedicated channels for lighting and sprinkler systems. A third installation option is to suspend the panels vertically. They can be used as shades, to establish a specific area, or even serve as signage. Different effects and treatments enhance aesthetics. Panels painted to match the substructure minimize the view of wires, plumbing, and ductwork.

Ceiling vents can also be screened with patented four-way ceiling diffuser grilles that complement the ceiling panels (US Patents No. D921174 for Decorative Patterns and No. D921175 for Standard Patterns). Requiring only that the housing grille be replaced, there is no need to replace the entire unit. The panels must only be cut to size and secured into the frame. For substructures that require maintenance, it is recommended that panels be installed into frames that can swing open.

[3]

[3]There are additional construction-related uses for expanded metal. Vent mesh is often used to prevent insects, birds, rodents, and, in some cases, embers from entering an attic or crawlspace. Its single-sheet composition will not burn, cannot be unraveled or easily penetrated, and allows air to circulate. Used as masonry reinforcement to minimize cracking, it is placed into the layer of mortar between a row of bricks. It can also be used for the keying of the mortar to support a brick or stone facade, and as plaster backing to reinforce areas around doors, windows, corners, or ceilings that are prone to cracking.

Engineered for strength and safety, expanded metal is a leading product for protecting, safeguarding, and enhancing both on and off the job site.

Manuel E. Menchaca is the senior marketing manager for Wallner Expac. He has worked for Wallner Expac for 10 years and specializes in writing, graphics, and marketing strategy. Menchaca holds a bachelor’s degree from California State University, Fullerton, and an MBA in Marketing from the University of Redlands. For more information, visit expac.com.

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/08/2025-09-MCN-Article-Hexagon-Ceiling-Panels.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/08/2025_09-MCN-Brick-pattern-expaneded-metal-panels.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/08/2025-09-Metal-Construction-News-Metal-Ceiling-Panels-Article-Painted-ceiling.jpg

Source URL: https://www.metalconstructionnews.com/articles/expanded-metal-ceiling-panels/