Fasteners and Metal Roofing

by Jonathan McGaha | 31 January 2017 12:00 am

As metal roofs have evolved, so have their fasteners

Metal roofing continues to grow in popularity across all segments of low-rise construction. Residential, agricultural and commercial structures increasingly feature light-gauge metal panels, often differing only in profile. The base structure of wood or metal requires different tools and fasteners to complete the job, but the installation process will be similar.

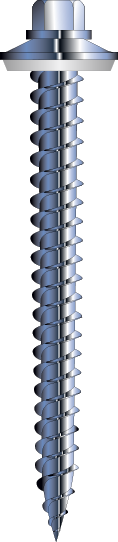

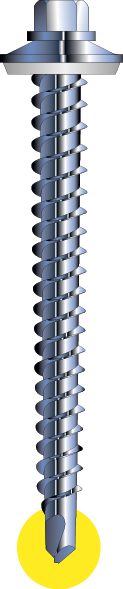

Residential panels are usually fastened to wood framing, calling for a sharp, piercing point screw, commonly #9 or #10 diameter. Lengths to accommodate the panel, underlayment and up to 1 1/2-inch penetration of the wood structure are required. Where a steel structure is used, choose a screw to protrude a minimum of three thread laps through the structural member to achieve full holding power.

Sealing washers are a must to ensure a leak-free roof. Assembled during manufacture, washers provide adequate sealing over a long life span. EPDM rubber washers produced from virgin material and backed with a galvanized or stainless metal washer provide long life sealing without deteriorating and leaking during the life of the roof.

Fastener Evolution

As metal roof panels have evolved, so have the array of fasteners designed for specific tasks. Other fasteners may include:

- Pancake head screws to answer hidden screw requirements where a hex head would interfere with overlapping panels.

- Metal panel to wood screws, equipped with a drill point, to ensure a clean penetration of multiple laps, and to drill heavy duty panels to 16-gauge thickness.

- Fasteners to #14 diameter, lengths to 8-inch for foam-backed panels or other unusual requirements, including gutter brackets.

- Wood screws and self-drilling screws with reaming wings. Wings enlarge the holes drilled in Fiberglass or PVC panels. The oversize holes allow for expansion/contraction without cracking.

Coatings and finishes continually improve to match the requirements of panel producers. The availability of a variety of colors and profiles helps account for the popularity of metal. Domestic fasteners continue to dominate where long life without corrosion is specified. A relatively thick zinc-based plating, when combined with a powder coated color matching finish, exceeds 2,500 hours in salt spray testing. This process will cost pennies more, but the result will be long lasting, and remain attractive for years. Where color match is not required, certain coatings that can match galvanized or Galvalume panels are available. These finishes, though not color matching, are also effective methods of preventing premature corrosion.

Tools to Drive Screws

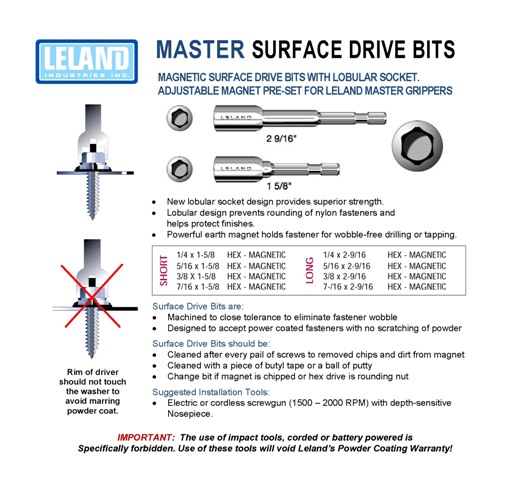

Installing metal roofing can be a simple process but requires care and expertise. Most electrical tool manufacturers offer a variety of products designed to drive small diameter screws:

Corded Screw Guns: The original: they have variable speeds of 0-2,500 RPM. Fifty years old, they are still versatile for driving wood screws or self drilling screws. Equipped with a depth-sensing nosepiece, this corded tool can’t be beat. The only drawback is the need for appropriate extension cords to reach the roof.

Battery Powered Drill/Drivers: They have 0-1,800 RPM, feature a drill chuck into which the installer inserts a hex driver bit, (surface drive bit) but, without a depth-sensing nosepiece, the installer pulls the tool away from the screw as it seats. They are a hit-or-miss proposition that can cause damage to the screw or panel.

Impact Drivers: They feature speeds up to 2,800 RPM, high-torque and 3,200 blows per minute. They are used by installers because of speed. Impact tools hammer the screw head damaging the coating or paint, and break up wood fibers, reducing the strip out values. Over-torque is dangerous when installing small diameter screws. Caution: domestic screw manufacturers void warranties when screws are driven with impact tools.

Dave Webster works at Leland Industries, Toronto. For more information, visit www.leland.ca[1] or call (416) 291-5308.

- www.leland.ca: http://www.leland.ca/

Source URL: https://www.metalconstructionnews.com/articles/fasteners-and-metal-roofing/