All About U

by Brooke Smith | 19 March 2024 11:09 am

[1]

[1]

R-value has long been the standard for assessing the insulative abilities of metal architectural elements. That is because R-value (where R stands for resistance) provides an accurate measure of how well a metal resists heat transfer, and it is a useful metric for static metal components like roofing materials and cladding.

But what about dynamic metal architectural elements, such as commercial rolling and sectional doors, that are designed for frequent movement? For doors like these, R-value tells only part of the story. To fully assess their insulative properties, designers and architects also need to consider their U-factor for a complete picture. (Note: Within the industry, U-factor is also often referred to as U-value, but to avoid confusion, U-factor will be used here.)

Why U-factor matters even more

When assessing the insulative properties of metal rolling doors and sectional doors, it is important to distinguish between R-value and U-factor, and to expect door manufacturers to provide both measures in their product specifications. While each measure should be considered when choosing this type of door, the U-factor is more useful when it comes to thermal performance. Here is why.

R-value measures the thermal resistance of a single material or component, indicating how good that component is at slowing down heat flow. As architects and designers know, the higher the R-value, the better the material is at insulating. But what is important to note is that R-value is used to measure the insulating properties of just a single component, not a complete assembly.

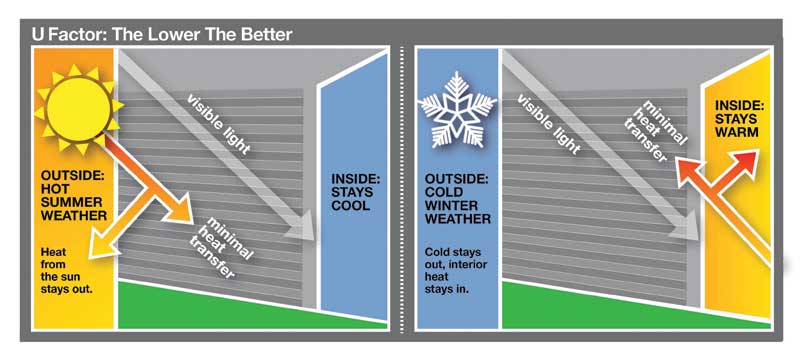

U-factor, on the other hand, measures the ability of an entire architectural assembly to conduct heat, and it includes all the materials in an assembly and their arrangement. Instead of measuring just the performance of insulated metal panels (IMPs) that may be only one part of a door’s construction (R-value), U-factor accounts for the door’s complete design and all its components, including the hood, bottom bar, and weatherstripping. This is especially important with doors because heat loss or gain happens not only through any door’s material, but also through air transfer around its perimeter.

Key takeaways

R-value is a measure of heat resistance and is useful for assessing a single building material or component like an IMP. A high R-value is desirable.

U-factor is a measure of heat conductivity, not of heat resistance; therefore, a low U-factor is desirable. U-factor is better for assessing multicomponent assemblies.

What to look for from a door manufacturer

Currently, many metal door manufacturers provide only R-values in their product specifications, which can make it difficult for builders and architects to select the most energy-efficient options for their clients and applications. The good news is a small number of manufacturers that recognize U-factor as an important tool in improving energy efficiency are leading the way to include this measure in their product specifications.

To expedite this change, building professionals can seek out the manufacturers that already provide U-factors in their product information and encourage more manufacturers to do so. Both are important steps toward creating more energy-efficient designs and happier clients.

Ian Hudock is associate product manager at Clopay Corporation in Mountain Top, Penn. Contact him at ihudock@clopay.com[2].

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2024/03/Clopay_U_Factor_Graphic.jpg

- ihudock@clopay.com: http://ihudock@clopay.com

Source URL: https://www.metalconstructionnews.com/articles/features/all-about-u/