Stand and Deliver

by marika_gabriel | 20 October 2023 12:00 pm

[1]

[1]When correctly specified and installed, a standing seam roof can easily last 60-plus years. Standing seam refers to a panel system attached to the building infrastructure with a clip or via a pre-punched fastening flange. The lack of exposed fasteners is the primary defining characteristic. Concealed fastener is another term for this panel family.

The attachment method directly impacts the performance and longevity of standing seam panel systems. Thermal cycling causes roof panels to expand and contract throughout the day as temperatures fluctuate. The clips used to attach standing seam panels accommodate the expansion and contraction. In contrast, exposed fastened panels do not. Instead, the fastener penetrating the panel pins it to the substrate, and the panel cannot move to accommodate the pressure applied. Over time, panels at lengths of 7.62 to 9.14 m (25 to 30 ft) can wear away around the fastener—referred to as slotting—and allow water to infiltrate the structure (see image).

[2]

[2] [3]

[3]The product offerings

Standing seam panels range in width from 304.8 to 609.6 mm (12 to 24 in.). Narrow panels tend to exhibit less oil canning while being more expensive to purchase and install than wider panels. As a result, 406.4- to 457.2-mm (16- to 18-in.) panels tend to be most popular for architectural applications, and 609.6-mm (24-in.) panels find their sweet spot in low-slope and low-visibility projects.

Manufacturers produce standing seam products from copper, aluminum, stainless steel, and metal. However, metal products such as Galvalume coated with a Kynar 500/ polyvinylidene difluoride (PVDF) finish are the most popular offerings based on cost, availability, and performance.

[4]

[4]The construction approach

Standing seam panels have become popular in new construction, retrofit, and recover applications. Retrofit projects involve an existing building with a flat (or very low sloped roof) and require framing to create a greater roof slope. Solving a problem like leaks is generally at the heart of a retrofit project, although buildings often look vastly different once complete (see before and after images on page 19).

The term recover is relatively new to the industry. A recover project involves an existing metal or shingle roof at the end of its serviceable life. Metal recover projects typically involve longer-length exposed fastened panels that experienced slotting due to the continual effects of expansion and contraction, as noted above. Shingle recover projects continue to gain momentum, as many building owners simply tire of the constant replacement cycle due to the shortened life expectancy of shingles.

[5]

[5]Regardless, often the most cost-effective and owner-friendly approach involves leaving the existing roof in place and installing new standing seam panels over the existing roof—hence the term recover. Recover projects save the cost of tear-off and disposal while providing enhanced product inventory and installer protection.

Panel types

While each manufacturer offers slight variations, there are three basic panel types: snap-on batten, integral lock, and mechanically seamed.

As the name implies, snap-on batten panels consist of two panels and a batten cap over the top. They tend to be referred to as water-shedding systems, which means they rely on a roofing product under them, such as a peel and stick underlayment to keep water from entering the building.

[6]

[6]In contrast, integral batten panels include the batten as part of the panel. While this difference may seem small, the performance is vastly improved. Integrated batten panels can typically span open framing, include a bead of factory-applied in-seam sealant, and often offer a weather-tightness warranty.

Mechanically seamed panels also typically offer factory-applied in-seam sealant; however, they require the use of an automated seaming machine to complete the installation process. Consequently, mechanically seamed panels tend to offer the greatest wind uplift values, can be installed at the lowest roof pitches, and frequently offer weather-tightness warranties.

[7]

[7]Panel styles

When discussing standing seam panels, it is essential to understand the difference between symmetrical and asymmetrical panels. As the name implies, symmetrical panels look the same on both sides, while asymmetrical panels differ on each side.

While that difference might seem minor, the implications are significant. Symmetrical panels allow installers to start and stop anywhere on the building. They can even skip challenging spots and return to them later. Beyond the benefits during construction, symmetrical panels offer the ability to replace a single panel in the field of the roof. The asymmetrical system, on the other hand, requires a predetermined left-to-right or right-to-left installation. It can be incredibly challenging, if not impossible, to repair an asymmetrical system once the building is complete.

[8]

[8] [9]

[9]Roof types

Some panel styles can span open framing up to 1.52 m (5 ft) on center, while others require a solid deck below the panels to provide necessary structural support. A few panel styles can be used successfully at slopes as low as 6.35:12 mm (0.25:12 in.).

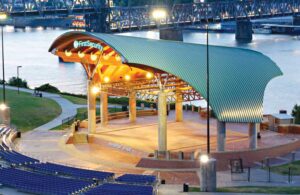

Many options exist when working with a typical plane or sloped style roof; however, the more experienced manufacturers also offer products to accomplish radius, tapered, and convex applications (see image).

Sloped metal roof projects tend to be the most common, although radius projects continue to gain in popularity thanks to technological advances. In the early days, radius roofs required manufacturers to curve the panels in the factory. As expected, this led to trucking limitations and high freight costs.

The next generation led to equipment that allowed contractors to curve simple pan and batten projects on-site. While that advance helped reduce freight costs and accomplish greater radii, the product style was still limited to a simple pan and batten system known as a water shedder.

In recent years, elite manufacturers dramatically improved their product offerings for radius roofs and began offering more robust systems. Some metal manufacturers offer the traditional pan and batten option but have also added three different mechanically seamed options with on-site curving capabilities.

The ability to curve on-site significantly reduces both production and transportation costs. Beyond the cost savings, on-site panel and curving production allows for much greater on-site flexibility to modify the radius and achieve the best result.

While most projects require curving of the panels, in some instances, panels can “walk” or install without curving. To determine the best product for a project, it is always recommended to reach out to a reputable panel manufacturer to discuss the project’s specifics.

Kathi Miller currently serves as the director of marketing and sales training at McElroy Metal. Kathi is a frequent contributor to industry trade publications where she shares knowledge developed over her 30-plus-year career in the metal roofing and siding industry.

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2024/01/First-Security-Riverfest-Stage_Maxima_Curved_Teal.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2024/01/Criminal-Justice-before12.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2024/01/Criminal-Justice-After.4.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/slotted-fastener.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/Lafayette-Hangar-During-Lafayette-LA-1.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/Carlinville-School-Carlinville-IL.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/Maxima-Tyler-Fire-Station-Medium-Bronze.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/Asymmetrical-Panel.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2023/10/Symmetrical-Panel.jpg

Source URL: https://www.metalconstructionnews.com/articles/features/stand-and-deliver/