Selecting an underlayment for stone-coated steel roofing

by Christopher Brinckerhoff | 27 January 2025 6:00 am

[1]

[1]A roofing underlayment is essential to the performance of the total roofing system. While the primary roofing material acts as the first defense for the structure, the underlayment plays the critical role of a secondary water-shedding membrane. Depending on the utilized type, the underlayment also provides additional protective benefits. Underlayment selection must consider the primary roofing material with which it will be paired. This article examines underlayment options that may be explicitly paired with stone-coated steel roofing. This ultra-lightweight material has become popular as a new construction and retrofit material.

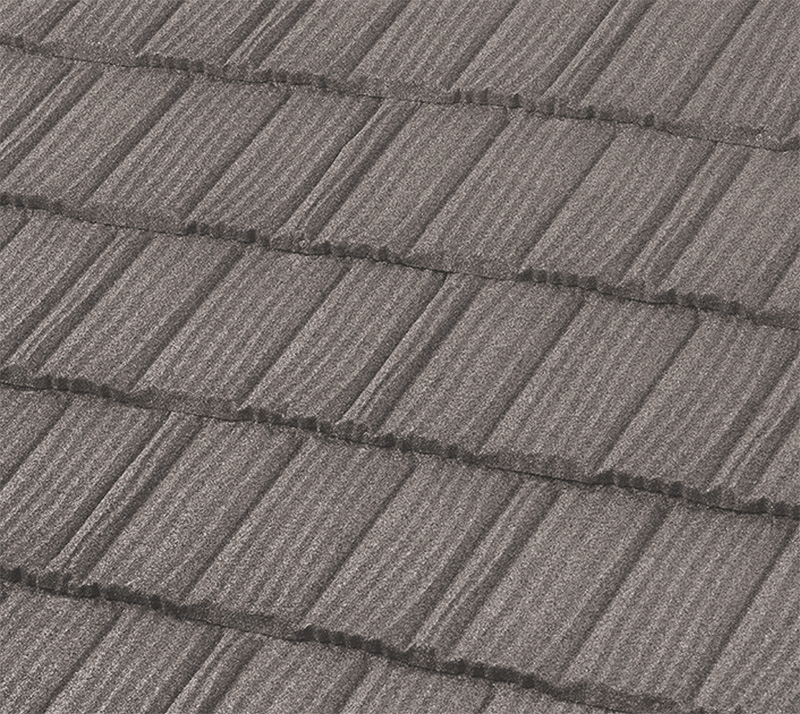

Things to know about stone-coated steel roofing

A steep slope material with numerous available profile and hue options, stone-coated steel roofing complements many architectural styles. Weighing just 0.68 kg per m2 (1.5 lbs per sf), the material is extremely lightweight, yet it benefits from the structural strength of steel. Thus, it is well suited for both retrofit and new construction applications. Stone-coated steel is durable and resilient in the face of hail and other extreme weather impacts such as ice damming, snow loads, wind uplift, and fire. Stone-coated steel (some options) is the only steep-slope metal roofing material that can offer both the Class 4 Hail Rating and Very Severe Hail (VSH) rating—the highest independently tested hail rating available for steep-slope roofing products.

Variables to consider when selecting the right underlayment

When deciding which underlayment is best for use with stone-coated steel, key considerations include region and climate. Each climate zone across the country is known for endemic weather conditions that the roof system must ultimately withstand. Some of the most common conditions a roof should ideally protect against are moisture, snow, heat, wind, hail, and fire. The risk of encountering each varies by region and climate zone.

Two common material types of underlayment are asphalt-based and synthetic (polymer). Both categories of underlayment have been modernized over the years, and today’s available options can perform well when paired with stone-coated steel, provided the underlayment is properly designed and applied.

Additionally, mechanically attached and self-adhered underlayments are approved under stone-coated steel with a minimum ASTM D226 Type II specification. The material should be rated at a high temperature when using a self-adhered underlayment. High-temperature underlayments mainly refer to self-adhered options containing asphalt as the primary adhesive to the decking. With this underlayment, melt points of the asphalt are a factor, as there are no fasteners to secure the underlayment. Excessive heat can displace the installed underlayment over time. High-temperature-rated underlayments can typically withstand temperatures over 121 C (250 F) and are considered premium products when used under stone-coated steel roofing. Self-adhered underlayments are specified under ASTM D1970 and are usually used as ice barriers but can be used in most climate applications.

[2]

[2]Mechanically attached underlayments do not require a high-temperature rating because the fasteners keep them in place on the roof deck. Depending on customer choice or local building requirements, the underlayment can be installed in a single or double layer, but it still requires the minimum ASTM D226 Type II specification.

Underlayment types and performance characteristics

Many underlayments may be ideally paired with stone-coated steel roofing. Each offers its own set of installation benefits, climate considerations, and performance characteristics, all of which should be considered when making a final selection. Ultimately, reputable, skilled roofing contractors will recommend which underlayment is best suited for the structure, identifying the most ideal option by factoring in all combined variables. For this reason, among many others, vetting any roofing contractor is critical.

[3]

[3]is best for use with stone-coated steel, key considerations include region and climate. Photo courtesy Westlake Royal Roofing Solutions

The options include:

Above-deck roof insulation: A complement to steep-slope roofing, this underlayment is a secondary water protective layer, energy-saving radiant barrier, and above-deck roof insulation blanket all-in-one. A high-polished aluminum facer with an embedded scrim lays on top of blown fiberglass insulation measuring approximately 9.5 mm (0.375 in.) in thickness. The underlayment reflects heat, provides a second layer of heat resistance, and can achieve minimum air-to-air values (when installed with elevated batten systems) for stone-coated steel roofing. External insulating underlayment options can incorporate an anti-glare coating, making the product easier and safer to install than alternative shiny radiant barrier products.

[4]

[4]Some of these underlayment options pass ASTM-E-108 Class A fire tests (when used with stone-coated steel roofing) and may offer certifications for Miami-Dade County NOA, Florida Product Approval, Cal Fire BLM listing, California Bureau of Household Goods and Services listing, and ASTM D226 Type II.

[5]

[5]SBS-modified 40#: SBS-modified, fiberglass-reinforced underlayment/base sheets are optimal for use with metal shingles, including stone-coated steel. Offering all-season durable protection, this underlayment is easily installed and can remain uncovered for up to 180 days without degrading. The SBS-modified asphalt is much more UV stable than saturated felt, minimizing the wrinkling and buckling common to non-modified membranes. Some of these underlays meet the physical requirements of ASTM-D226 Type II. Additional certifications include ASTM-D4601, D6757, and D4869 Type IV.

Self-adhered base sheets: The SBS-modified asphalt core of this type of underlayment self-seals around the nail or screw penetrations when mechanically fixing roofing. Compared to mechanically fastened base sheets, the sealing it provides to the roof deck offers moisture resistance, added security against leaks, and thermal stability. A peal-and-stick application may be installed in high wind conditions, and no special tools or hot asphalt are required for hot mopping. The poly-faced surface provides foot traction and maximum adhesion of cap sheets or two-ply systems.

[6]

[6]Premium high-temperature, self-adhered underlayments: These underlayment options are ideal for use in nearly all climates. The material provides durable protection by bonding to the base sheet or the roof deck. An SBS-modified asphalt core is tested to seal around fastener penetrations, eliminating the need for so many nails into the roof sheeting. Premium high-temperature underlayment is easy to install and provides a highly slip-resistant surface, making it a preferred choice for metal roofers. The high-strength, polyester surface, and SBS-modified asphalt adhesive meet national and Florida building code requirements and are rated 127 C (260 F).

Synthetic: Synthetic underlayments are ideal for steep-slope roofing installations. Patented nail gasketing technology and four-layer construction ensure the stone-coated steel roof the underlayment accompanies is better able to withstand the elements in all climates and seasons. Coupled with UV and thermally stable materials, the synthetic underlayment’s nail gasketing technology allows it to be left uncovered and exposed to the elements for up to 180 days without degradation. High grip backing and a non-woven thermally embossed fiber face increase deck grab and superior walkability. Identifiable lay lines and fastening markers also enable a swift and hassle-free installation. Some options of this underlayment type meet the physical properties of ASTM D226 Types I and II and comply with AC188, ASTM D1970, Section 7.9., and ASTM D8257.

Heavy-duty modified asphalt reinforced underlayment: Heavy-duty underlayments comprised of modified asphalt and reinforced with an extra heavy fiberglass mat uniformly sealed to the roof deck and around nail and fastener penetrations. This underlayment protects the structure against damage caused by ice dams and wind-driven rain. It is easily installed in cold or warm climates, requiring no special tools or equipment. Opaque granules on the surface provide excellent traction during installation and protect against UV. The underlayment offers an aggressive bond at low temperatures and is a good choice for the roof’s critical areas, including valleys, perimeters, eaves, chimneys, walls, dormers, and skylights. Additionally, the underlayment may be installed by-directionally without needing a salvage edge to form a sealed headlap.

Notably, a few underlayment types will perform across all climate regions. These include external insulating underlayment, synthetic, and premium high-temperature self-adhered options. The underlayment selection should not impact the warranty for the roof if it aligns with the manufacturer’s stated specification, which should always be completely followed.

Doug Thagard is the business development manager for roof system components with Westlake Royal Roofing Solutions. Contact Doug at dthagard@westlake.com or visit westlakeroyalroofing.com[7].

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-2.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-1.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-3.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-6-1.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-4.jpg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/01/Photo-5.jpg

- westlakeroyalroofing.com: http://www.westlakeroyalroofing.com/

Source URL: https://www.metalconstructionnews.com/articles/features/underlayment-steel-roofing/