Field-Applied Coating Advantages on Metal

by Mark Robins | 1 May 2022 12:00 am

Field-applied coating advantages saving money and standing the test of time

Well-designed metal roofs and walls offer a host of advantages, including energy efficiency, durability, sustainability and aesthetics. However, in the absence of proper protection and routine upkeep, some of these benefits can be compromised or lost.

Field-applied, air-dry coatings are a great repair and restoration option to enhance performance, longevity and aesthetics of metal building components. From restoring a piece of metal architecture after years of weathering or making spot repairs, a high-quality air-dry system can

be a gamechanger. In fact, some field-applied paints are engineered to deliver the same level of factory-applied performance when it comes to chemical and weather resistance, and protection against chalking, fading, marring, abrasion and UV light.

When properly applied, the coating protects the metal building against corrosion, thereby enhancing the enclosure’s ability to deliver strong thermal performance and energy efficiency. Durable coatings also provide an effective shield from the harmful effects of rain, snow, wind and hail to further enhance the metal roof and walls’ resiliency and endurance.

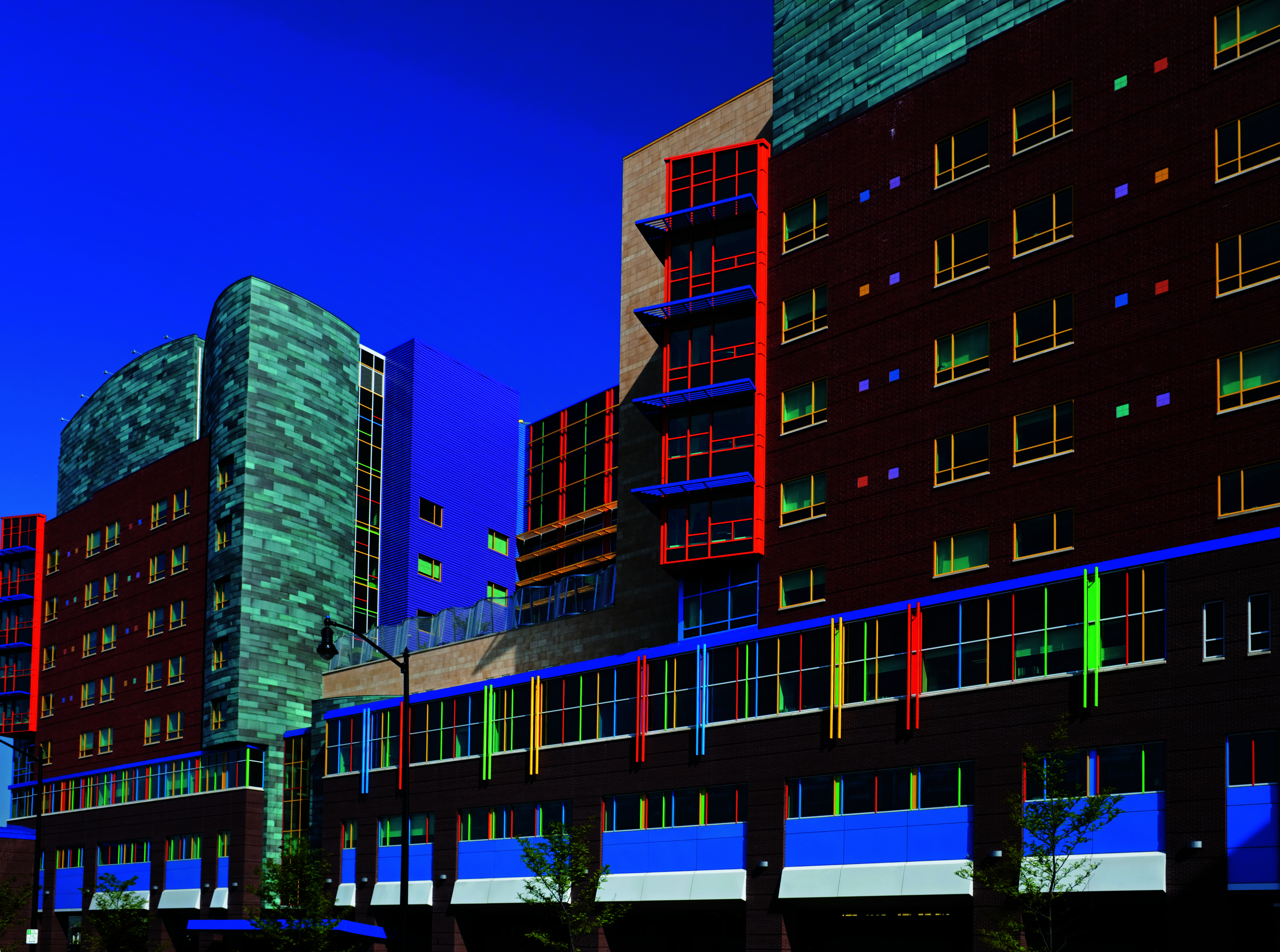

Vivid Colors

But performance is only half the story. Field-applied coatings also make strong contributions to a building’s appearance. In the case of an older, weathered structure, the right application can breathe new life into the building by upgrading its aesthetics. While generic paints can provide immediate results, the effects will be short-lived. Chipping, fading and discoloration tend to start within months with lower-quality coatings.

Conversely, air-dry systems are carefully engineered and tested to deliver long-lasting results that rival factory-applied performance, making them perfectly suited for the restoration and repair of weathered architectural metal panels and accents.

Applicable for building panels, window mullions, roofs and other applications, air-dry coatings are available in an extensive palette of colors and solid, brighter mica and metallic finishes. Specifically made for metals, these coatings offer excellent color and gloss retention for lasting beauty and are environmentally advantaged with low volatile organic compound (VOC) content.

Top Quality, Top Results

When utilizing an air-dry coating, it is important to select a certified contractor who is experienced in evaluating the existing coating of an older facility, and correctly prepping and thinning the subsurface prior to the two-step, airdry application.

PPG CORAFLON ADS is a field-applied, two-component air-dry fluoropolymer coating for building and roof restoration and touchups, as well as structural steel projects that can be applied by spray, brush or roller. It is formulated to meet FGIA/AAMA 2605 performance specifications.

The low-maintenance and long-lasting air-dry system finish is resistant to chalking, fading, marring and abrasion and is optimized for restoration of weathered architectural metals. This makes it a valuable tool to help preserve and protect a structures beauty and integrity long into the future.

Gary Edgar is the national coil and extrusion specification manager for Pittsburgh-based PPG Building Products. To learn more, call (800) 258-6398 or visit ppgindustrialcoatings.com[1].

- ppgindustrialcoatings.com: http://ppgindustrialcoatings.com

Source URL: https://www.metalconstructionnews.com/articles/field-applied-coating-advantages/