Installation Methods for ACM Panels

by Mark Robins | 3 October 2022 12:00 am

Understand ACM installation, and how it can impact schedules and budget

With ACM panels being one of the last materials installed on the project, it is important to understand the various types of installation systems and how they can impact the overall project schedule and budget.

Field-Fabricated Installation Systems

Field-fabricated installation systems can be assembled by the installer while on the job site. The installer will order the panels and system components and perform all the needed cuts in the field. The most common field-fabricated systems are: one-piece, two-piece moldings, clip-and-caulk, and face fastened.

The one-piece molding system uses aluminum moldings to encapsulate panel edges. The two-piece molding system has a base extrusion attached to the wall and a faceplate that is then snapped into place. Molding systems are typically available in both flat and reveal styles, providing two different aesthetics. A standard H molding provides a monolithic or continuous look, while the H reveal molding highlights the joint. One main benefit is that the sealant is usually captured in the moldings, protecting it from UV exposure.

The clip-and-caulk installation system utilizes hidden clips to fasten and join the panels. The panel joints are then sealed with caulk, which conceals the fasteners. Color-matched caulk can give a beautiful monochromatic look while contrasting caulk can be used with eye-pleasing results. A face-fastened system typically features small visible fasteners attaching the corners of the ACM panels to the wall assembly.

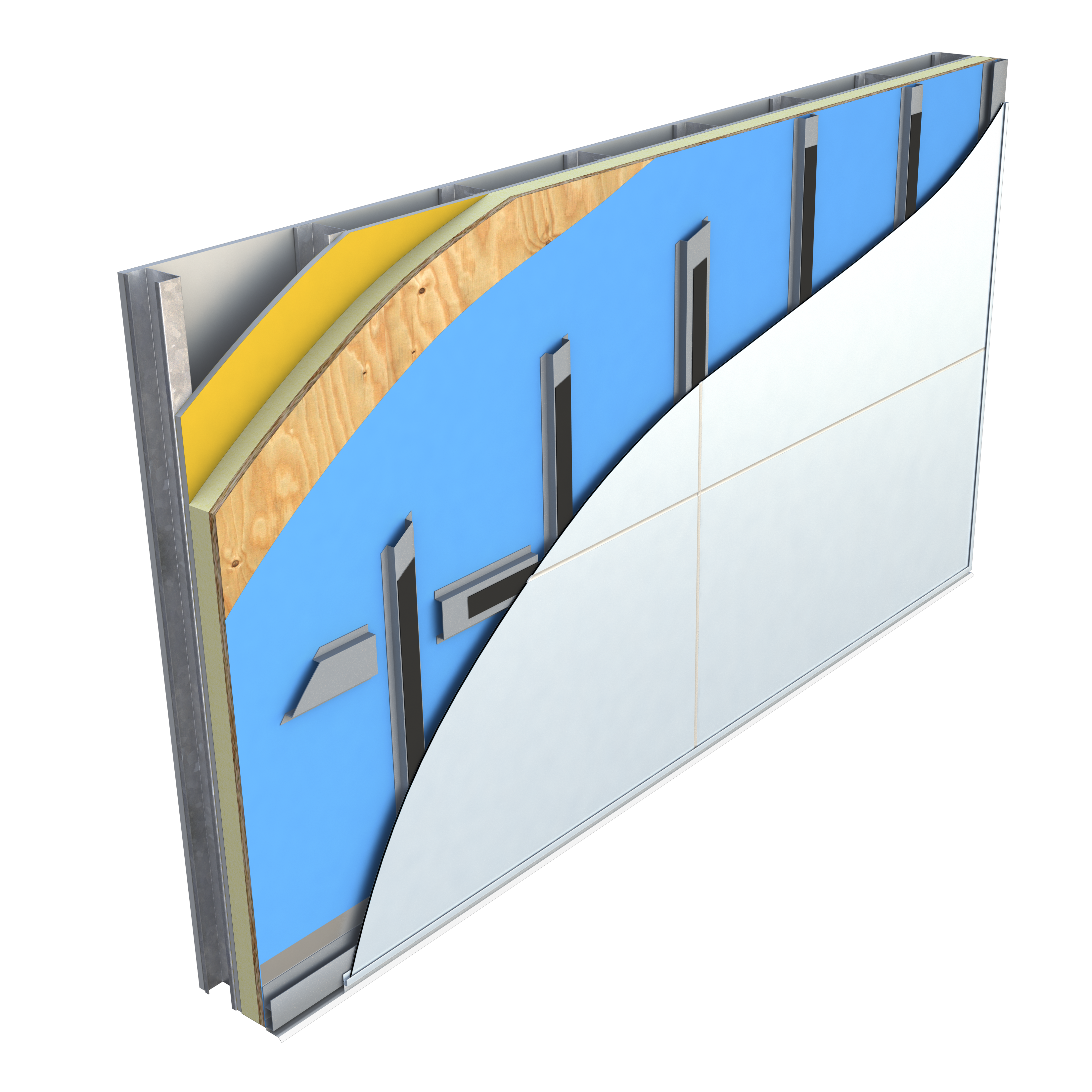

Shop-Fabricated Installation Systems

Shop-fabricated refers to systems in which the panels are typically routed, bent and fabricated in an off-site shop environment. The most common shop-fabricated systems are rout-and-return wet seal, and rout-and-return dry seal.

1-piece, tight-fit molding

A wet-seal installation uses caulk to seal the panel joints. This system looks very much like the clip-and- caulk system but includes the return legs and a clip at the backside of the panel along with backer rod and caulk at the joint. A dry-seal installation creates an open, deep-reveal joint and incorporates methods to promote drainage and drying behind the cladding.

Both shop-fabricated systems are considered rainscreen systems. However, some are also available as a pressure-equalized system meaning the pressure outside and behind the panel can equalize rapidly so negative pressure does not pull moisture into the wall cavity.

Field-Fabricated vs. Shop-Fabricated Systems

A major benefit to field-fabricated installation systems is that they can be fully fabricated at the job site, leading to faster install times and greater flexibility for adjustments during construction to the as-built conditions. Often, projects are not built 100% to plan, which requires on-site modifications making these systems faster solutions because material is on-site to accommodate the change.

Shop-fabricated installation systems often utilize a third-party fabricator or the panel manufacturer to fabricate the panels, instead of the installer. This typically adds time and cost to the project. In addition, if there were unforeseen changes implemented during construction, the installer must rely on the fabricator to remake the panel module at the shop facility.

Additional Considerations

What is the desired look? Some systems provide very different aesthetics when compared to others. Budget is typically what drives this decision. What’s the total installed cost? Look beyond the panel cost and factor in the labor for a true cost.

What testing has been performed and does it meet the requirements of the project? Is NFPA 285 required? How much continuous insulation is required? All the assembly components must be able to work together.

Are complete installation instructions, specifications, details and drawings readily available? How accessible is the manufacturer to assist with technical questions, and design and installation assistance? Call and see how responsive they are!

Lastly, and an important factor in today’s environment, how long will it take for the material to be delivered and are there minimums for standard or custom finishes?

Be sure to go beyond the ACM panel and select an installation system that not only meets the project requirements but also gives you the biggest value and overall piece of mind.

Shawn Crouthamel, CSI, CDT, is the architectural national sales manager at Laminators Inc., Hatfield, Pa. To learn more, call (800) 523-2347, email shawn.crouthamel@laminatorsinc.com[1] or visit www.laminatorsinc.com[2].

- shawn.crouthamel@laminatorsinc.com: mailto:shawn.crouthamel@laminatorsinc.com

- www.laminatorsinc.com: http://www.laminatorsinc.com/

Source URL: https://www.metalconstructionnews.com/articles/installation-methods-for-acm-panels/