Insulated Metals Panels: An Effective All-In-One Building Component

by Mark Robins | 1 December 2020 12:00 am

Helping bring peace of mind on fire performance

To help solve the building code compliance puzzle, manufacturers have responded by providing design teams with an envelope solution to meet the challenges of stringent code requirements. Ensuring fire safety and being sensitive to energy costs and impacts, manufacturers have developed new technologies that provide energy performance far beyond typical buildings in the past. It is important to understand that many of these components (insulations, air/water barriers) may provide this improved performance at the trade-off of introducing what the building codes considers to be combustible materials into the building assembly.

The Building Envelope Puzzle and Code Compliance

Acknowledging the challenge of balancing energy performance with fire safety, code officials and fire safety organizations have developed requirements allowing combustible materials to be used in various construction types. This has occurred while including more stringent fire performance criteria for these materials to help ensure a safe environment.

The building code has addressed the importance of fire safety for combustible components through work with standardized testing organizations such as ASTM and NFPA, and FM and UL certifications resulting in code sections especially developed to implement these standards. Although ASTM E84 and full-scale testing like FM4880, NFPA 286 and UL 1040 help predict the performance of combustible materials in fire situations, the tests do not necessarily address all possible scenarios that may affect fire propagation.

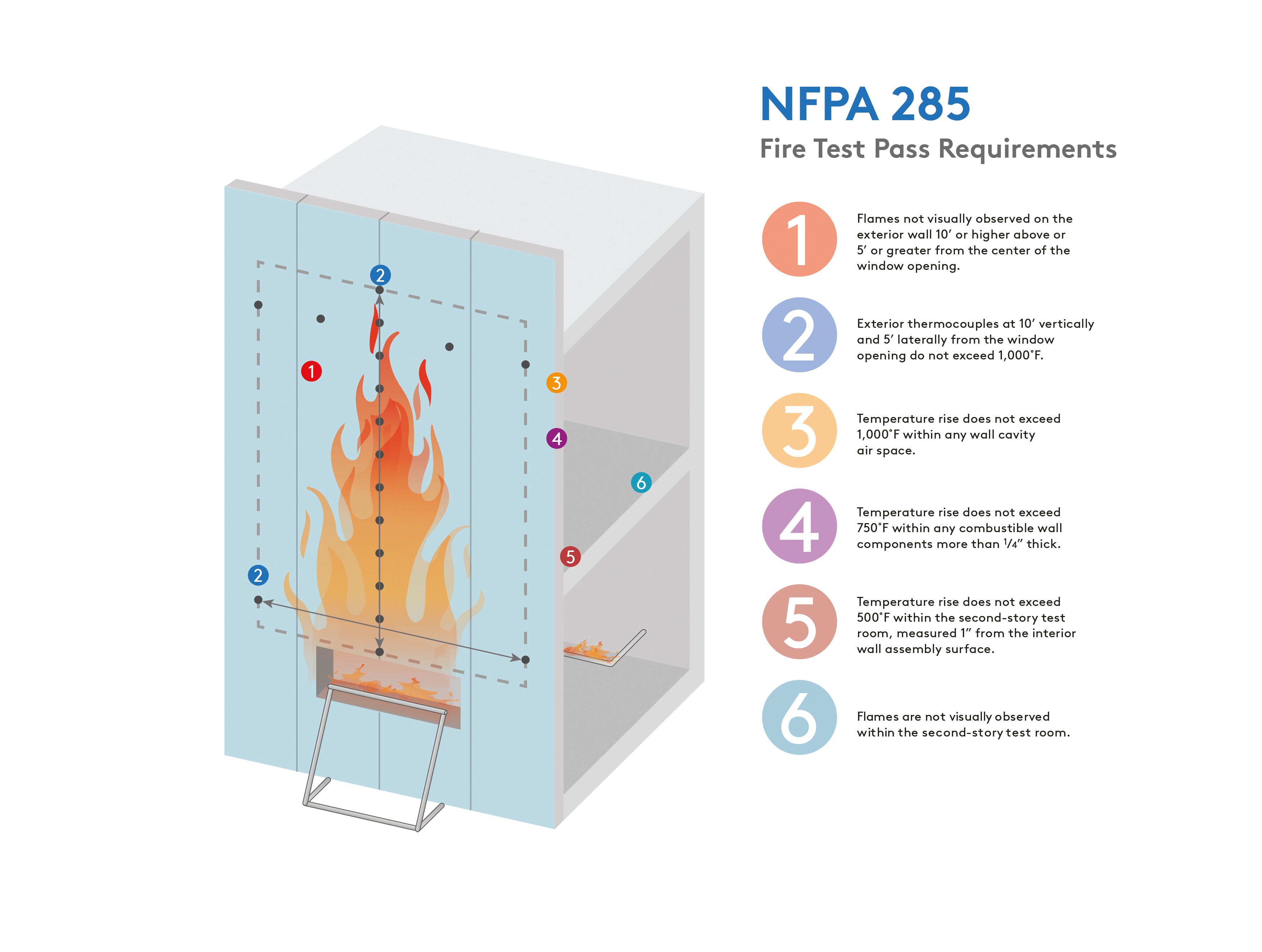

NFPA 285 Code-Compliant System

The NFPA 285 test was developed to evaluate vertical and lateral fire propagation for wall assemblies that contain combustible components such as foam plastic insulation, combustible exterior façade elements and some air/water barrier materials. Since its introduction, the NFPA 285 test has proven to be a valuable means of evaluating more complex wall assemblies. The critical aspect of NFPA 285 is that it is an assembly test, meaning that the components in question are not being evaluated in isolation, but rather tested as part of the actual wall assembly design being proposed. This allows not only the material being evaluated to be tested, but also any possible interactions with other materials, cavities, etc., that may affect the overall performance of the assembly.

The NFPA 285 test is comprised of a two-story chamber where one wall is a sample of the wall assembly being tested. The test assembly’s lower story includes an opening (simulating a window) and fire sources are located within the lower story room and at the window opening itself. The test assembly is instrumented with thermocouples at various locations and subjected to a multitiered intensity fire source. The pass/fail criteria include:

1. Flames not visually observed on the exterior wall 10 feet or higher above or 5 feet or greater from the center of the window opening.

2. Exterior thermocouples at 10 feet vertically and 5 feet laterally from the window opening do not exceed 1,000 F.

3. Temperature rise does not exceed 1,000 F within any wall cavity air space.

4. Temperature rise does not exceed 750 F within any combustible wall components more than 1/4-inch thick.

5. Temperature rise does not exceed 500 F within the second-story test room, measured 1-inch from the interior wall assembly surface.

6. Flames are not visually observed within the second-story test room.

In support of their products, IMP manufacturers have performed and passed the NFPA 285 in most common wall configurations for their products and several wall assemblies where the IMP may be one of several components. As with all combustible wall components, specifiers should request appropriate documentation to ensure code compliance.

Designers can have peace of mind knowing fire safety is not compromised. Code requirements and stringent test standards were developed specifically to provide design flexibility at the same time. The all-in-one component of an insulating metal panel provides the confidence necessary to help designers create the highest efficiency building envelope.

Ian Manser is technical director at Kingspan Insulated Panels Inc., Deland, Fla. To learn more, visit www.kingspanpanels.us[1].

- www.kingspanpanels.us: http://www.kingspanpanels.us

Source URL: https://www.metalconstructionnews.com/articles/insulated-metals-panels-an-effective-all-in-one-building-component/