Lightning Protection Primer

by Mark Robins | 1 April 2020 12:00 am

Five key things to learn about lightning protection

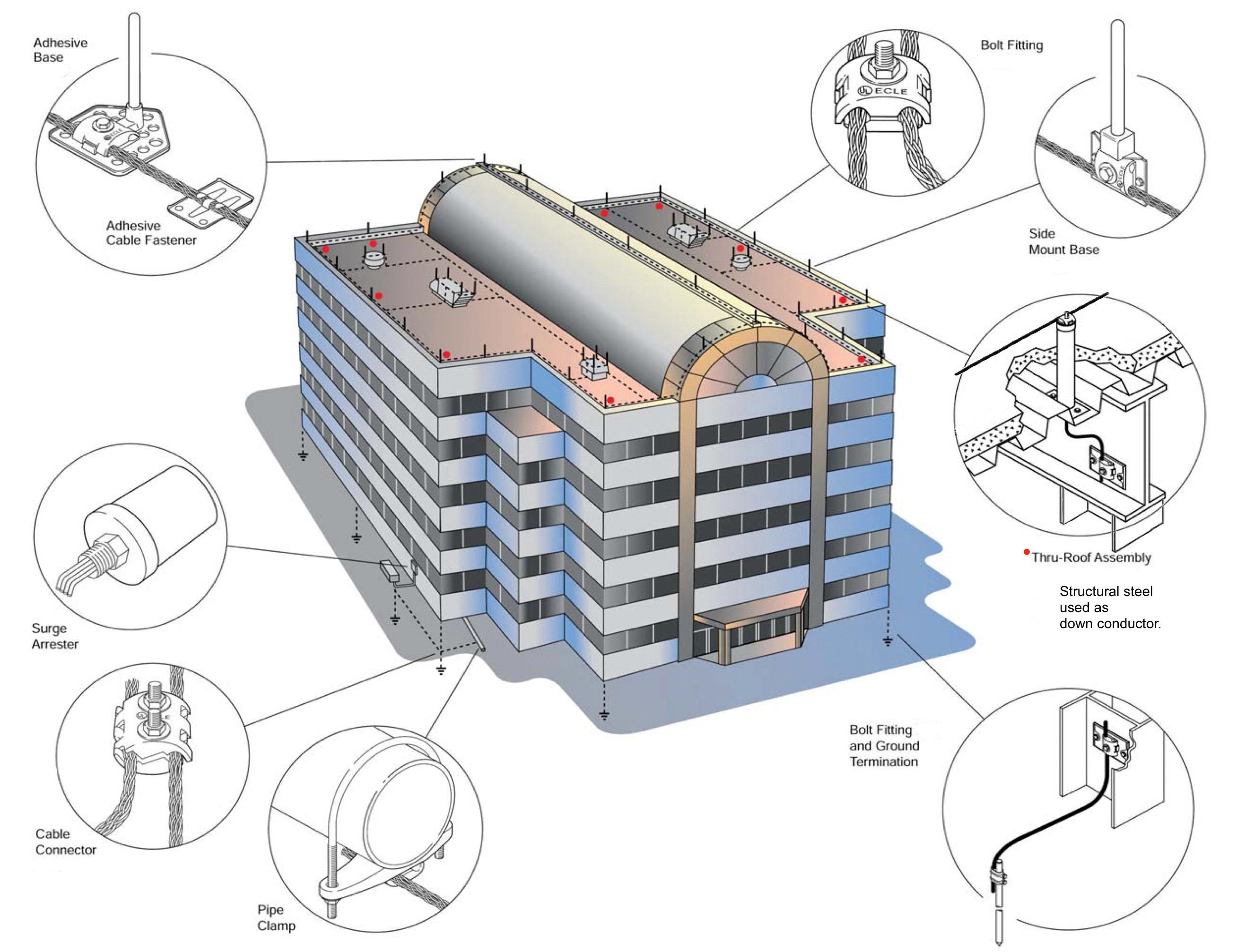

Lightning protection requires a complete system with multiple, interconnected low-resistance paths that safely conduct lightning between the sky and Earth without damaging a building or its contents. (Photo courtesy of East Coast Lightning Equipment Inc.)

To determine if a building needs protection, building designers and owners can use the Lightning Risk Assessment in National Fire Protection Association’s NFPA 780—Standard for the Installation of Lightning Protection Systems. These calculations can be easily performed online athttp://bit.ly/LightningRisk[1].

1. Who to Call

Design of LPS should be delegated to a firm employing individuals certified by the Lightning Protection Institute (LPI). Communicate with the LPS designer so you both understand project conditions and can optimize the LPS for efficient installation. Careful planning can minimize costs and maintain project aesthetics. LPS is not a do-it-yourself job or one that most electrical or roofing contractors know how to handle. It should be subcontracted to firms specializing in lightning protection.

2. A Complete System

An LPS creates multiple, interconnected low-resistance paths that safely conduct lightning between Earth and sky. LPS installers may be one of the first trades on-site and one of the last to leave. Early work can include installing ground electrodes and interconnecting LPS to footings, and other work that will be buried.

Grounds are usually made with copper-clad steel ground rods driven 10 feet into the ground. Where ground rods cannot be used, such as rocky soils or ledges, copper ground plates can be employed or lightning conductor cables can be installed in a ground loop around building.

Air terminals, also known as lightning rods, are located on roof’s perimeter and high points, on rooftop equipment, and at other locations required by standards. In some cases, handrails, roof ladders and other metal fabrications can be used as strike termination devices in lieu of air terminals. Air terminals are interconnected with a network of conductor cables.

The cables are run as down conductors between ground and roof. The thick, braided cables are sized so that lightning flows through them with nil resistance or heat generation. In structural steel-framed buildings, the steel may be used as down conductors in lieu of cables.

Cables also bond the LPS to other building grounds; the electrical, plumbing and mechanical systems; and to other metal bodies in the building. The goal is to create equal electrical potential throughout structure so lightning doesn’t flash (arc) from one part of building to. Making these bonds and interconnections requires cooperation between trades. Power and signal lines entering a building must be equipped with listed surge protective devices.

The ground for the lightning protection system marked with counterpoise tag) has to be interconnected with other building grounds and bonded to the gas, water and electric systems (see red tag). (Photo courtesy of Mr. Lightning)

3. Remodeling and Reroofing

Once LPS is installed, train your crew to avoid damaging LPS components. For example, removing the hood from a rooftop exhaust fan can damage LPS components and connections, and may require the lightning protection specialist to reestablish connections.

Specialists should also be on-site during reroofing to remove LPS components without damaging them, mark locations of through-roof penetrations that will be covered by new roofing and then restore the lightning protection.

The LPS will have to be extended to protect new additions, bond new equipment and systems, and protect new services entering the building. Disruptions to LPS should be coordinated with the building owner and not made when thunderstorms are forecast. Scaffolding may require temporary connection to the LPS if not within the zone of protection provided by the LPS.

4. Close-Out

At the end of the job, the installer may need to make connections to items, such as security cameras, that have been installed since previous visits. It is recommended that job specifications call for the LPI-IP Master Certification for lightning protection systems. To obtain the Master Certification, the LPS contractor will schedule an inspection by an LPI-IP inspector, who will verify that the LPS is installed in accordance with NFPA and UL requirements, and issue the certification to the building owner.

5. Job-site Safety

When working outdoors or in unenclosed structures, remember: When Thunder Roars, Go Indoors! Do not wait until the storm is overhead; immediately seek shelter in enclosed buildings or vehicles with metal roofs, and stay sheltered until 30 minutes after the storm passes.

Plan for weather-related delays in the construction schedule and in subcontracts. Include lightning in emergency plans and safety training. Be prepared to administer first aid to anyone injured by lightning. More safety tips are at www.weather.gov/safety/lightning-job[2].

Jennifer Morgan is co-owner of East Coast Lightning Equipment Inc., Winsted, Conn. Michael Chusid is an architect and building products consultant. To learn more, visit ww.ecle.biz[3].

- http://bit.ly/LightningRisk: http://bit.ly/LightningRisk

- www.weather.gov/safety/lightning-job: http://www.weather.gov/safety/lightning-job

- ww.ecle.biz: http://ww.ecle.biz/

Source URL: https://www.metalconstructionnews.com/articles/lightning-protection-primer/