Metal Retrofit Roofing versus Competitors

by Paul Deffenbaugh | 1 September 2020 12:00 am

A Look During the COVID-19 Pandemic

Contractors and manufacturers in the metal building and metal roofing public markets, such as schools and other public buildings, need to know how metal retrofit roofing can help stabilize this volatility. Stability is what everyone is searching for, and metal retrofit roofing can be a major stabilizer.

Metal retrofit roofing is considered building infrastructure and, as such, has been getting ample attention on a national and local level. The American Society of Civil Engineers[1] (ASCE) has been conducting studies concerning all infrastructure, including sanitary, water, roads, dams, buildings (including roofing) as well as many other areas. It has been determined, without a doubt, that our current funding has been far less than that needed to keep up with deteriorating infrastructure elements. Currently, there are numerous national and local initiatives being brought forward to fill this disparity of required funds.

Ponding on flat roof

The current Covid-19 pandemic has only made the necessity of securing these roof infrastructure funds more important. Maintenance, repair and/ or replacement of these infrastructure elements are required for our society and they will not heal themselves if we do nothing. Dollars can be found for these essential elements and this is necessary work even in the middle of this pandemic. It helps to understand which roof systems perform best, and building owners need factual analysis to analyze which roof system is the most cost effective as far into the future as can be scientifically expected.

Of course, any interest in this market requires an analysis of the market and the competitor products available in the retrofit roofing market. For the purposes of this article, we will use the public K-12 school market as an example. This market is second only to the federal market in size of total roof area of buildings. While the federal market uses metal retrofit roofing extensively, the design and construction process is overwhelmed with paperwork, making it difficult for firms to compete.

Caption: This metal roof cost analysis compares metal roof retrofits to flat membrane and sloped shingle roof systems. Since metal roofs can last 60 years, its lifetime cost after maintenance and replacement, is significantly lower than either of the other roofing materials. This is based on 60,000-square-foot roof.

The school market, though, is divided into thousands of school districts, all of which have major control over their budgets and financing options. This makes them more disposed to common sense and cost-effective roofing solutions whose benefits over other choices can be easily explained and understood.

Over the last 50 years, the school market has used mainly flat roofing systems, starting with built-up roofs using layers of felt and hot asphalt to bind them together. Later came the single-ply roof systems, starting with EPDM in the 1970s and leading to the PVC, TPO and modified bitumen roofs during the ensuing years. These materials age at different rates due to UV rays, moisture and temperature fluctuations. These external atmospheric conditions cause the particular weathering membrane to start losing its elasticity and water prevention capabilities, making them more vulnerable to water traveling through these systems and into the interior of the school.

Also, throughout this time frame, the roof designs remained mostly flat with less than 1/4-inch in 12-inch slope. Flat design allows for deflections and result in ponding water on many areas of the roofs. Combining the deterioration of the weathering membrane and constant water ponding causes leaks, which continue to worsen with time. So, when it is time to repair or replace one of these flat single-ply roofs, do the owners want to replace it with the same roof system that has failed or look to another solution that will last considerably longer, even as long as the building lasts? At that decision point is when a metal retrofit solution can make headway.

In contrast to the flat roof systems which cover the majority of school roofs built in the 1960s through 1980s, a metal retrofit roof system will alleviate the two main problems with a flat roof:

- The metal retrofit roof system will add slope to the flat roof (greater than 1/4-inch in 12 inches).

- The weathering surface will be a Galvalume-coated steel material what is not affected by UV, and has only minimal reduction in its protective coating due to atmospheric elements. Let us break down these two positive differentials that metal has over its competitor systems:

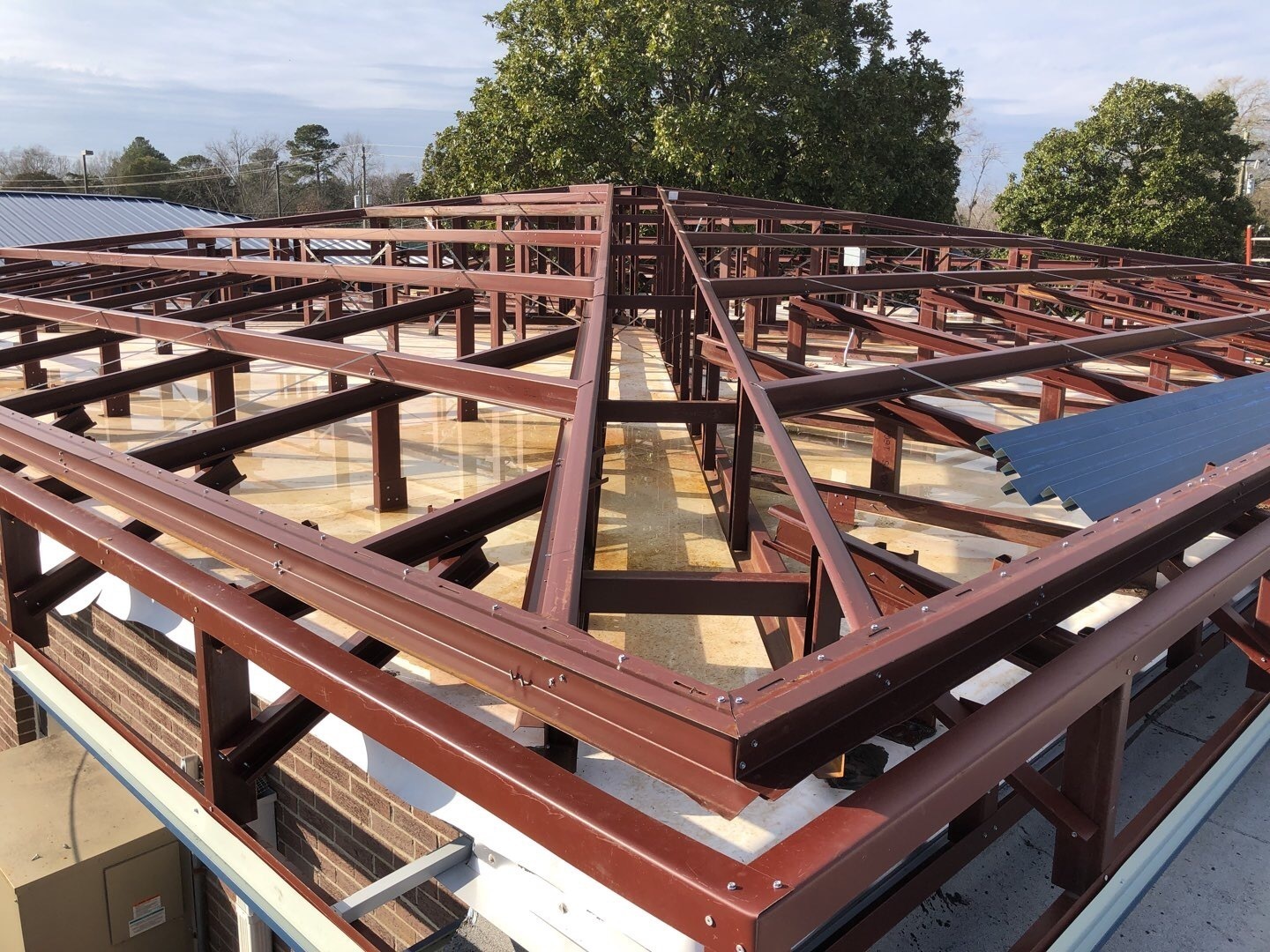

Adding Slope: A light-gauge steel framing system can be designed and installed directly over an existing flat roof without needing to remove the existing roof per all current building codes in acceptance of International Building Code standards. This framing system is designed to load the existing structural system in a uniform manner similar to the roof’s original design. The system creates a new roof cavity, which must be ventilated and where additional insulation can be installed. (If the existing membrane is undisturbed, updating insulation is not required.)

The advantages over the flat systems are that the existing roof does not need to be removed. This removal must be done by code if there is more than one roof in place prior to reroofing. It is not required if a light-gauge steel framing system is used to add slope and whose load is carried on the roof’s main structural elements. A ventilated cavity and additional insulation will reduce the energy loss through the roof, lowering the building’s heating and cooling operating costs.

In contrast to the flat roof systems which cover the majority of school roofs built in the 1960s through 1980s, a metal retrofit roof system will alleviate the two main problems with a flat roof:

1. The metal retrofit roof system will add slope to the flat roof (greater than 1/4-inch in 12 inches).

2. The weathering surface will be a Galvalumecoated steel material what is not affected by UV, and has only minimal reduction in its protective coating due to atmospheric elements. Let us break down these two positive differentials that metal has over its competitor systems:

Adding Slope: A light-gauge steel framing system can be designed and installed directly over an existing flat roof without needing to remove the existing roof per all current building codes in acceptance of International Building Code standards. This framing system is designed to load the existing structural system in a uniform manner similar to the roof’s original design. The system creates a new roof cavity, which must be ventilated and where additional insulation can be installed. (If the existing membrane is undisturbed, updating insulation is not required.)

The advantages over the flat systems are that the existing roof does not need to be removed. This removal must be done by code if there is more than one roof in place prior to reroofing. It is not required if a light-gauge steel framing system is used to add slope and whose load is carried on the roof’s main structural elements. A ventilated cavity and additional insulation will reduce the energy loss through the roof, lowering the building’s heating and cooling operating costs.

The panel selection process can be made using the published structural values from a large selection of metal roof manufacturers. The engineering necessary to satisfy the building code can be supported by a licensed engineer experienced with light-gauge construction and knowledge of the structural capacities of all of the materials involved. Finally, the actual construction of the system can be installed by a qualified metal roofing company.

During these Covid-19 times contractors and manufacturers are looking for ways to minimize the uncertainty of the roofing market’s future. With metal roof repair and replacement being the second largest drain on school facilities’ budgets— second only to HVAC repair and replacement— repairing and reroofing financial decisions will be highly scrutinized. The contractors and manufacturers will need to educate the owners about the comparison of maintaining an existing, leaking flat roof; or replacing it with the same system and expecting different results; or replacing it with a metal retrofit roof solution, which will probably never need to be replaced and will cost approximately one-third of the old flat system.

Metal retrofit roofing has been around for over 50 years with millions of square feet successfully installed on school facilities alone. These roofs will protect the contents, teachers and students for well over 60 years at the lowest life cycle costs of all roofing systems. Its history of success is welcome news for school facilities that continue to suffer with the mess and costs associated with leaking flat roofs, especially when they think their only choice is replacing them with the same systems that have already failed in 20 years or less.

Even in these turbulent times, school systems are still required to analyze and find funding for the facilities’ roofs. Contractors and manufacturers committed to pursue this market and willing to commit the time and money to educate the school owner, will have the opportunity to find some stability now and will be positioned for continued stability and ample work when we get beyond this pandemic.

Chuck Howard, PE, Metal Roof Consultants[2], Cary, N.C., is a member of the Metal Construction Hall of Fame, a frequent contributor and speaker on metal roofing issues, and has been a leader in the metal roofing industry for more than 30 years.

- American Society of Civil Engineers: https://www.asce.org/

- Metal Roof Consultants: https://metalroofconsultants.net/

Source URL: https://www.metalconstructionnews.com/articles/metal-retrofit-roofing-versus-competitors/