Metal Roofing Safety Essentials

by Mark Robins | 3 January 2022 12:00 am

A comprehensive safety program, monitoring, training and the right equipment keep roofing crews safe

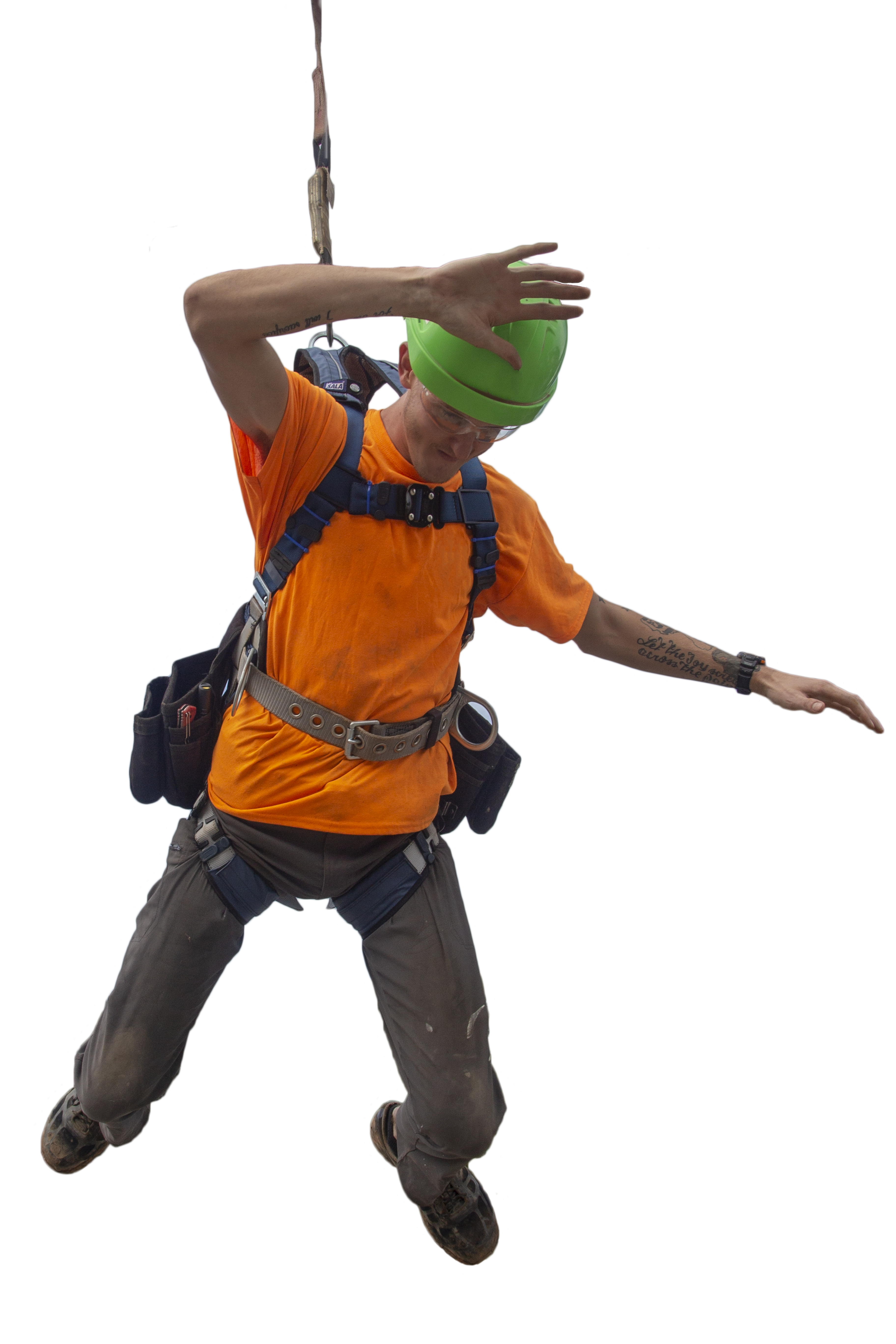

The correct fall prevention equipment keeps workers safe. (Photo courtesy of HySafe)

Roofers encounter many hazards on the job, including hazards associated with working at heights and from ladders, power tools, electricity and extreme temperatures. Unless these hazards are controlled by the employer, roofers risk serious injury, illness and death.

A Positive Safety Culture

All employers in the construction industry must have a safety program. Roof safety must be actively managed. To protect workers on roofing jobs, employers must identify the hazards present, take steps to address them and have a company culture that puts safety first.

Worker safety must be considered when working around roof hatches. Photo: Gill Cuoto Photography, courtesy of BILCO)

Rich Trewyn, director of enterprise risk management at National Roofing Contractors Association[1] (NRCA), stresses, “It’s very important that companies focus on building a positive safety culture within their companies. Key to that success is ensuring management and field staff come to a consensus of what works for the safety and well-being of all employees. Development and implementation of safety and training support those decisions and is of the utmost importance. Safety should be well thought out in advance of any project. Do everything you can to utilize the tools NRCA and others make available to build awareness. Planning for and training to these hazards is key to stemming their occurrences. Properly addressing issues before they arise is especially key to avoiding costly claims, and more importantly saving lives and reducing injuries.”

Joseph Allen, project manager, safety and training manager at Thomas Phoenix International[2], Eastampton, N.J., stresses there must be open lines of communication between the field and office. “Employees are sometimes reluctant to talk to management about safety infractions, so it’s imperative to maintain confidentiality and promote a positive safety culture.”

In terms of communication, Jason Harrell, vice president of Harrell Construction[3], Jacksonville, Fla., says, “I like to discuss safety situations with employees and installers individually—this reinforces safety as a core company belief. I like there to be feedback as well. Sometimes we forget sitting in the office that the guys on the crew doing the work every day want to be safe and have some very good ideas on how to get the job done safely.”

Fall protection aims to stop a fall before the worker hits the ground or any level below the roof. (Photo courtesy of Thomas Phoenix International)

According to the Bureau of Labor Statistics, 401 of the 1,061 construction fatalities in 2019 were caused by falls from elevation. All of these deaths are preventable.

A company’s safety program can involve preplanning meetings where safety concerns can be discussed. Harrell says, “A pre-roofing meeting gets employee buy-in on the roofing safety plan and comments to verify management and safety supervisors didn’t miss anything. Crews must have an understanding of what their safety equipment is and how it works. We discuss where each system’s weakness is and how to mitigate that risk the best. Typically starting with the roof is the most difficult since this work is typically done from inside a lift, then transitioning from the lift to a standing seam stanchion and retractable system.”

At Houston-based Chamberlin Roofing and Waterproofing[5], pre-start meetings before the project start date identify access points, materials, procedures and fall protection. “Each employee is empowered to stop the job for unsafe/hazardous situations and correct them,” says Jorge Hermosillo, Chamberlin’s safety manager.

To help companies ensure safety on a metal roof, Occupational Safety and Health Administration (OSHA) stresses a Plan, Provide and Train doctrine. Employers need to “PLAN” ahead to get the job done safely. Employers need to develop a plan and ensure the proper equipment, material and appropriately trained workers are available. Know the pitch of the roof and follow the appropriate standard. Employers must “PROVIDE” the right equipment. Employers must provide fall protection and the right equipment for the job, including the right kinds of ladders, scaffolds and safety gear. Employers must “TRAIN” workers to use the equipment safely. Employers must train workers in hazard recognition and in the care and safe use of ladders, scaffolds, fall protection systems and other equipment they will be using on the job.

Enforce and Monitor

Implement safe work practices to reduce the possibility of falls. Supervise workers to ensure fall protection equipment is used and maintained correctly. Lead by example. Employers, project managers, and supervisors should follow the rules they are responsible for enforcing.

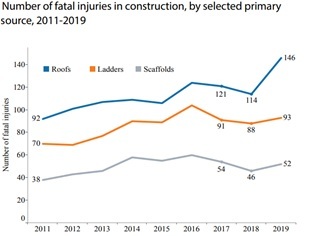

(Chart: Brown, S., Harris, W., Brooks, R. D., & Dong, X.S., 2021. Fatal Injury Trends in the Construction Industry. Data Bulletin, courtesy of Thomas Phoenix International)

As fall-related injuries and fatalities still exist, it is imperative that companies properly train employees for these exposures. Properly addressing issues before they arise is especially key to avoiding costly claims and more importantly saving lives and reducing injuries.

Rich Trewyn, director of enterprise risk management at National Roofing Contractors Association

“Monitor, monitor, monitor,” stresses Harrell. “On every project, every employee is empowered to stop production for safety reasons. We use pre-roofing meetings, discuss safety rules and the use of fall arrest systems while installing and while relocating. We discuss material loading for install so everyone on the job knows the safety expectations. After that you’re not enforcing, its maintenance. If someone can’t follow the rules after thorough planning, they just have to find another line of work. It’s not worth a fall or an accident due to neglect.”

Trewyn says it’s imperative that companies have competent and qualified persons on their job sites to predetermine issues that could arise and address them before they occur. “A simple job hazard analysis (JHA) can help to identify tasks which may have risk; address the risk and pre-plan a safe solution prior to the job beginning. JHAs can be helpful tools to do this; however, issues can arise day to day and a JHA should be updated to address these new issues.”

Hermosillo encourages teamwork and the authorization to stop work when hazards arise so they can be properly addressed. “Ensure a daily safe working plan is discussed and understood. Pre-planning safety processes can include JHA, pre-task planning (PTP), safe performance self-assessment (SPSA) and more. Safety monitoring can be accomplished by job walks looking specifically for hazards by all levels of company employees: crew members, foreman, superintendents, project managers and safety professionals.”

At Columbus, Kan.-based Crossland Construction[6], steel area superintendent Jake Doss mandates 6-foot fall protection for everyone and agrees with supervisor pre-planning of work with daily pre-tasks. “[Also,] have high penalties for noncompliance. The penalty must be high enough to make employees and bosses understand they will be in serious trouble for noncompliance. Make the penalty higher for noncompliance than the reward for breaking the rules. Reward employees for working safely and for stopping unsafe acts or turning in near misses. Inspect more frequently.”

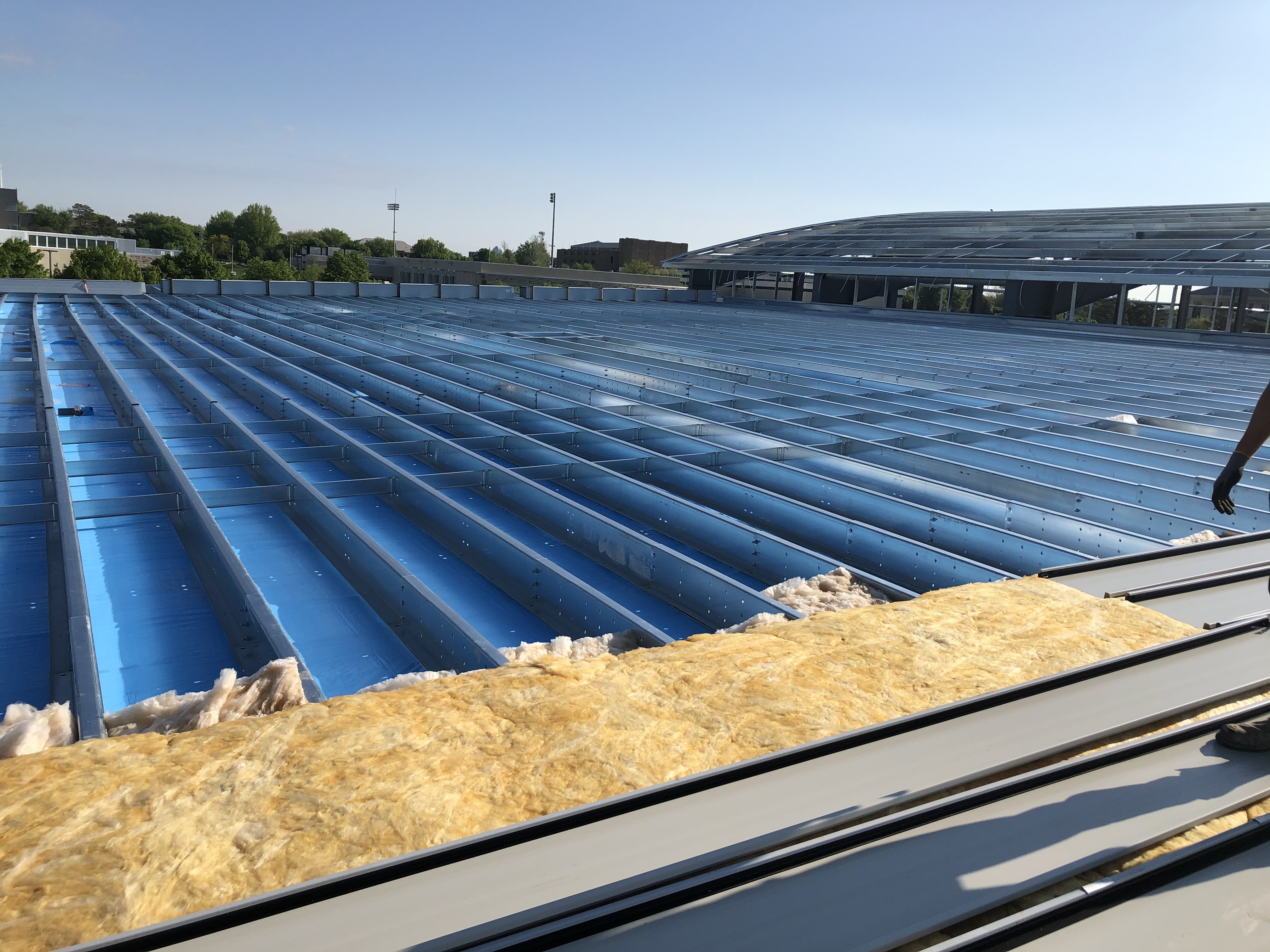

Metal roof construction can present trip and fall hazards. (Photo courtesy of Crossland Construction)

Allen agrees to successfully enforce and monitor, conduct frequent job site visits and document the results of any findings, positive or negative. “This information can be used to reward employees who are doing the right thing, or to recommend more training when it’s needed. Include written job-site audits as part of routine site visits and have the foremen sign off on them. This can be coupled with incentives for foremen who consistently follow protocol. Have a documented fall protection plan for every project. This can be templated for standard jobs. Make sure employees are aware which fall protection systems are allowed. Maintain strict anonymity for employees who express safety concerns. Never betray their confidence. Require re-training for workers who do not follow correct procedures.”

Metal Roof Safety Training

Employees must be trained to safely perform all assigned task and be accountable for applying these skills on the job. Employers must provide training in a language and in a manner that workers can understand. The safety training must be conducted by a competent person and include information on how to recognize hazards and on what procedures to follow to minimize them. Retraining is required when previous training becomes obsolete due to changes in work conditions, protection systems or equipment. Retraining is also required when worker performance indicates a need for it. In this training, it is important to discuss tool safety features, safe operating procedures, and safe work practices, such as proper body placement and how to use personal protective equipment (PPE).

The OSHA Training Institute partners with 27 OSHA Training Institute Education Centers at 42 locations throughout the United States to deliver courses on OSHA standards and occupational safety and health topics.

To ensure roof safety, Doug Westervelt, safety director at Crossland Construction, stresses the importance of setting up a training program and requiring a certain amount of training per year. Also, “Have fall protection companies bring their fall truck out and show demonstrations. They do this for free.”

To prevent falls on roofs, workers need to be aware of roof layouts. (Photo courtesy of Crossland Construction)

Harrell relies on safety equipment vendors to provide proper training and use of their specific equipment. “Equipment rental companies are invaluable when high lift training is needed or when specialty training for things swing stages is required.” New Braunfels, Texas-based A-Lert Roof Systems has a comprehensive Behavior Safety Program specially designed around OSHA and other federal standards for the roofing industry. Properly trained and educated A-Lert employees drive a safety culture where accidents are less likely to happen. New hires are required to complete an eight-hour safety training program before beginning work in the field. General foremen are required to complete a 10-hour OSHA certified construction outreach training course. Its Target Zero slogan is a reinforcement of training concepts and a reminder of the continuing goal of zero workplace accidents.

At Chamberlin, Hermosillo explains scope-specific training is best, specifically identifying hazards that will be faced and providing workable solutions. This involves, “Training on fall protection systems and fall prevention measures (engineering and administrative solutions), and conducting hands-on training sessions for system users (adjusting protection and fall arrest systems, using and setting different anchor points).”

Allen says that for steel erectors, training in fall hazard recognition, and fall protection systems and equipment must include learning the differences between Subpart M and Subpart R regulations. Also, “During fall protection basic training, we show each employee how to properly don and adjust their harnesses, and demonstrate the differences between various lanyards, self-retracting lifelines (SRLs) and anchorages. The most effective part of the initial training is simulating elevated roof tie-off. Describe a roofing work task and allow the employee to select the proper equipment, anchorage, and anchorage location. It’s far better to have the employees demonstrate their knowledge and make mistakes in the training stages. A mistake on the job site might not lend the luxury of re-training. The Metal Building Contractors and Erectors Association (MBCEA) offers Fall Protection Basics and Controlled Decking Zone training modules for use to members, as well as related toolbox talks. Membership also grants access to the Metal Buildings Institute’s Quality and Craftsmanship video series.”

Trewyn explains safety training is not just a one-off event and stresses the importance of updating a company’s safety training. “As new and innovative safety products are developed, companies should consider retraining as a key component to their overall safety program. NRCA has recently developed a new three-day Fall Protection Competent Person Class which takes a look at the leading cause of fatalities in the industry. This class will prepare workers for the issues faced daily on our job sites and benefit companies by meeting OSHA requirements and industry best practices specific to training.”

Obviously, Fall Protection

Saftey must be a top priority for workers on metal roofs. (Photo courtesy of Lemartec)

The number one most cited OSHA violation in U.S. companies is fall protection compliance. Falls from heights are dangerous and a frequent cause of injuries, hospital trips, and worker’s compensation payouts. Fall protection aims to stop a fall before the worker hits the ground or any level below the roof. Fall protection systems are requisite to reduce the risk of injury or death of a roofer working on roofs.

OSHA regulations require any roofer who works six feet or more above a lower level to use an adequate fall protection system. A fall protection program is a crucial business decision to prevent injuries, save lives, and save money, and fall protection equipment is a necessary part of these programs.

At Harrell Construction, Harrell says, “Fall protection plans are discussed upfront in the beginning of the job, reviewed, modified and then reviewed again; long before the roofing is ready to install.” At Crossland Construction, Westervelt says it uses multiple options for fall protection for different roofs: sky web, safety nets, simple saver, laminator system, purlin glide system and standing seam anchor points.

According to Allen, “Because falls account for over 36% construction fatalities [Brown et al., 2021, p.3], fall hazard recognition training is the first step in avoidance. It’s important not to overestimate anyone’s experience or common sense. Statistically, someone falls to their death every day, and roofs are the leading cause. Consider the best fall protection options for each job, and make sure that approved means are communicated and understood in writing. If a company’s jobs are all similar, a template can easily be re-used for each project. If jobs vary wildly from one to the next, it’s all the more reason to document what fall protection methods are allowed on each site. As part of our AC478 management system, we have a written fall protection plan for each project.”

Other Metal Roof Hazards

Historically, claims involving falls from heights are still at the top of the Bureau of Labor Statistics (BLS) numbers. But, Trewyn says a trend that has reemerged is fall-through claims; falling through bad decking, skylights and holes, specifically. “NRCA is working to develop programs and tools to assist in determining issues with potential fall-through claims like our new Roof Deck Integrity Assessment Tool JHA template, along with our three-day Fall Protection Competent Person course. Upon successful completion of this course, students will meet OSHA’s requirements for a competent person and qualified person for safety monitor and fall protection training.”

Allen cautions that, “Old roofs can have translucent panels, which have been painted over with topcoat. These may look just like a metal panel until someone tries to walk over it. Always try to walk on old roofs with your weight over the purlin lines. On screw-down roofs, this is along the screw lines. On standing seam roofs, you can often see a swell in the seams where clips are located.”

A common metal roof safety concern is housekeeping, and because of this Hermosillo cautions you must be aware of all trades on the job site and the actions they take that may create slip/trip hazards. Harrell agrees saying housekeeping on a roof is a source of concern because mud, dirt and spilled liquids all can cause tripping hazards. Harrell adds, “Unsecured construction materials or debris—small items like small insulation pieces, tape mastic paper, plastic bags from screws, etc., can be a problem. But, if winds get heavy, panels and trim pieces are a big danger. We use clips with strapping to assist in securing the materials that have to be on the roof—specifically overnight and weekends—and keep small debris to a minimum by containing trash and securing it then removing from the roof two to three times a day.”

- National Roofing Contractors Association: http://www.nrca.net

- Thomas Phoenix International: http://www.thomasphoenix.com

- Harrell Construction: http://www.harrell-construction.com

- 3M Fall Protection Busines: http://www.mmm.com

- Chamberlin Roofing and Waterproofing: http://www.chamberlinltd.com

- Crossland Construction: http://www.crossland.com

- www.bilco.com: http://www.bilco.com/

- [Image]: http://www.bilco.com

- www.hysafe.com: http://www.hysafe.com/

- [Image]: http://www.hysafe.com

Source URL: https://www.metalconstructionnews.com/articles/metal-roofing-safety-essentials/

[8](Photo: Gill Cuoto Photography, courtesy of BILCO)

[8](Photo: Gill Cuoto Photography, courtesy of BILCO) [10](Photo courtesy of HySafe)

[10](Photo courtesy of HySafe)