Mezzanines: All About the Flooring

by Jonathan McGaha | 31 March 2016 12:00 am

Mezzanines offer extra room for storage, offices and recreation

Mezzanines-raised platforms that are independent of a building structure-are popular for adding floor space. Supported by columns or cantilevered, they offer extra room for storage, offices and recreation, or they can serve as connectors to office space.

Mezzanines-raised platforms that are independent of a building structure-are popular for adding floor space. Supported by columns or cantilevered, they offer extra room for storage, offices and recreation, or they can serve as connectors to office space.

Quick to install and cost effective, mezzanine floor material varies by application, but is frequently made of heavy-duty steel, aluminum or fiberglass. In industrial settings, where mezzanines are built around stationary equipment, grating is a customary flooring. It provides easy access to machinery for maintenance, a safe, non-slip walking surface to help avoid falls, and its openings allow easy cleaning and visibility.

Choices of grating products by commercial and residential builders and designers often differ from industrial users. Grating aesthetics are as important as the practical qualities of safety, ease of cleaning, durability and load-bearing properties essential to industry.

Office Connection

In a unique example, a commercial office mezzanine was built in and around recycled shipping containers that house office space. The brightly colored containers were positioned into multilevel office pods with an outdoor mezzanine platform built as a connector.

Tampa, Fla.-based McNICHOLS Co.’s traction tread plank was used as the mezzanine flooring, selected from among McNICHOLS’ five grating products that also include bar grating, expanded, pultruded and molded fiberglass.

For the office pod project, the plank offered the practicality coveted by industrial users, with smaller holes, less weight and greater design compatibility. With its hundreds of raised perforated buttons with debossed holes, the traction tread plank provides slip resistance in all directions. This plank product is useful anywhere light, slip-resistant flooring is required, which makes it ideal for pedestrian traffic. ADA-compliant, it is easy to install and has a long service life. Surface patterns include diamond, slotted, small hole, large hole, serrated solid and vented, and rectangular.

Extending Second Floor

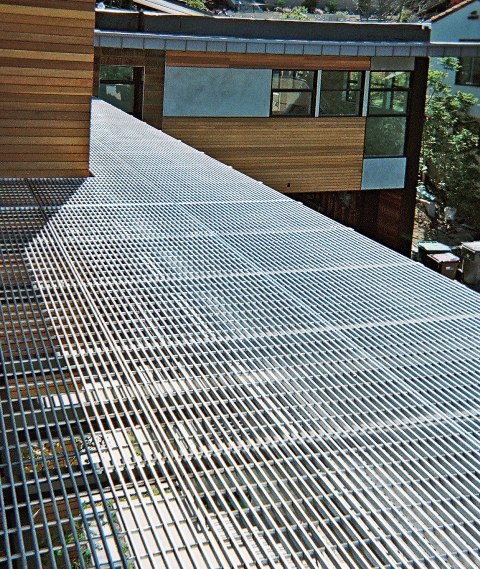

Another example where grating played a major role is the outdoor mezzanine of an Oakland, Calif., residence. Using McNICHOLS’ aluminum swage locked bar grating, the designer/fabricator created additional recreation space between the first and second level. The bar grating doubles as a sunshade and as a way to access the home’s exterior for maintenance.

This mezzanine example⎯with 1 by 3/16-inch bearing bars, 1- to 3/16-inch on-center and regular cross bars 4 inches on-center⎯is walkable, has a handrail-enclosed section for outdoor entertainment, and sufficient openings to filter sun.

Benefits of Grating Products

Benefits of Grating Products

- Grating choices: bar, plank, molded and pultruded styles.

- Materials options: steel, aluminum, fiberglass, powdercoated steel, stainless steel and galvanized steel.

- Qualities: strength, safety and weight, load bearing capabilities, open area and easy fabrication.

- Applications: mezzanines, platforms, flooring, walkways, trenches, as well as vertical applications such as partitions, fencing and infill panels.

- Durable: meet almost any load bearing or weight requirement and sturdy for rugged applications.

Benefits of Bar Grating

- Popular: a top choice for strength, safety and long-term cost.

- Selection: available in a variety of panel sizes; barsizes and spacing, bar shapes and material types. The most popular style is welded bar grating.

- Strong: consists of a series of bearing bars welded (or otherwise joined) at various intervals to perpendicular cross bars to form a load-bearing panel. Panels are manufactured by welding, locked by swaging or press-locked processes.

- Bearing bars: typical panel configuration has bearing bars spaced 1 3/16 inches (center to center) with perpendicular cross bars spaced 4 inches apart (center to center). Other spacing is available to meet loading and open area requirements.

Benefits of Plank Grating

- Field handling: one-piece construction product allows easy field handling and cutting.

- Construction: made of formed and punched sheet metal or aluminum extrusion. Formed metal planks are available in galvanized, stainless, and plain steel and aluminum. They come in a variety of heights and widths for almost every application.

- Styles: variety of channel configurations, some with interlocking choices, and walkway styles with integral toe plates.

- Surfaces: choice of openings include diamond, rectangular, slotted or round shaped, and solid surfaces. Most planks are lightweight and offer significantly higher slip resistance surfaces than bar grating styles.

Other types of grating, each with their own unique benefits, include expanded, pultruded and molded fiberglass. They come in a variety of opening shapes and sizes. Expanded grating is available in aluminum, plain and stainless steel. Pultruded fiberglass bar grating, made with a high percent of glass within the laminate, provides high strength and load capacity. Molded fiberglass is a good choice where corrosion resistance, fire retardancy and high-impact resistance are important.

Mary Estes, principal of Tampa, Fla.-based Estes & Co., is a freelance writer who contributes articles to trade journals in industries including metal supply and manufacturing, health care and technology. To learn more about Tampa-based McNichols Co., visit www.mcnichols.com[1].

Endnotes:- www.mcnichols.com: http://www.mcnichols.com

Source URL: https://www.metalconstructionnews.com/articles/mezzanines-all-about-the-flooring/