Not Just a Metal Building

by Jonathan McGaha | 1 August 2014 12:00 am

With BIM technology, custom-designed metal buildings are exciting with endless possibilities

The metal building industry is alive and well and continually evolving. Every manufacturer is vying for that competitive edge that sets them apart. Metal buildings aren’t just metal buildings anymore. They are aesthetically pleasing with unique designs while accomplishing architectural feats. The choices are endless, from curved roofs and walls to skewed ridgelines and heavier crane systems. The use of tapered shapes provides a competitive edge to supply lighter frames and meet the unique design challenges that normally wouldn’t fit in the scope of a traditional metal building system.

A good metal building manufacturer can offer quality products at a competitive price within a timeline while providing great customer service throughout the process. Estimating and design become extremely important to the contractors and end users who want a hands-on approach using state-of-the-art technology. This technology is constantly progressing and today’s manufacturer has to keep up with those changes if it wants to stay in the game.

|

From estimating to the construction plan phase, Building Information Modeling (BIM) has transformed the delivery of projects. Drafting software has moved from being a simple substitute for the drafting board to being utilized as a design tool for the production of 4-D models and integrated drawings.

Project teams are now able to build a structure twice: once virtually and once physically. Design activities are integrated across disciplines while construction activities are clean and clear throughout the distinct supply chain stages. The outcome is a savings in costs and scheduling, resulting in enhanced project quality and enriched project collaboration.

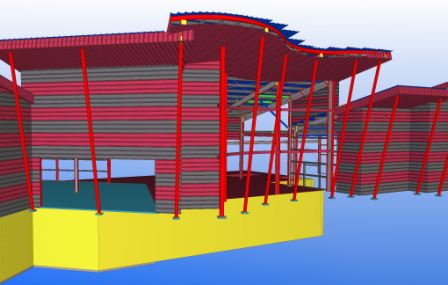

Using Tekla Structures and BIM allow economic, social and environmental elements to be dynamically and precisely assessed during the project’s design phase. This produces a clean and true virtual picture of a project that seamlessly becomes reality on the construction site. Though, used primarily in the conventional steel industry since its inception, Tekla Structures has a rich toolset allowing it to be developed further to work in the metal building industry. It opens the opportunity to create a unique structure that meets the customer’s needs and enhances the value of the end product. It also allows the freedom to move from the traditionally designed project to meet an ever-changing industry.

At the Hanford Reach Interpretive Center in Richland, Wash., a close working relationship between the architect Terence L. Thornhill, the builder Richland-based DGR Grant Construction Inc. and Airway Heights, Wash.-based Garco Building Systems, the building manufacturer was key to the success of the project. A requirement on the original request for proposal was that the structure be a custom- designed metal building. DGR Grant presented Garco Building Systems with Thornhill’s conceptual drawings and Garco’s BIM detailing group prepared several building models. In the true spirit of BIM, these became the model from which the fabrication and erection drawings were produced.

|

Because of the angles and curves involved in this building, software made it achievable. Garco took on this project with confidence since they had advanced software as a detailing tool and a competitive price. Garco was able to produce a building that was a quality project, a structure that would be fitting for DGR Grant Construction with minimum problems and struggles.

In today’s construction industry, metal buildings are capturing an increasing share of the nonresidential construction market. Not only have there been significant improvements in the architectural appeal over the last several years, there are also huge benefits such as strength, durability, recyclability, energy efficiency and shorter construction times. In 2013, approximately 75 percent of low-rise buildings were custom-designed metal buildings and a little over 400 million square feet of low-rise metal buildings were constructed.

When we say the metal building industry is alive and well and continually changing, we mean it. The metal buildings of the past are gone and replaced by unique and eye-appealing metal structures. The future is metal buildings with award-winning architecture and functionalities that far surpass history. Using BIM technology, the future of custom-designed metal buildings is exciting with endless possibilities.

Joanie Garvin is the marketing services administrator, Jeremy Gross is the BIM drafting manager and Karl Stranberg is the senior software engineer at Garco Building Systems, Airway Heights, Wash. To learn more, go to www.garcobuildings.com[1].

- www.garcobuildings.com: http://www.garcobuildings.com

Source URL: https://www.metalconstructionnews.com/articles/not-just-a-metal-building/