Roof Penetrations and Insulated Metal Panels

by Mark Robins | 1 July 2021 12:00 am

Understand the dynamics roof penetrations larger than pipe flashings for IMP roofs

IMPs’ Unique Properties

This is not new technology; IMPs have simply become more accessible and practical for use on low-rise commercial buildings as energy codes have expanded into new regions. As an all-in-one assembly that contains the roof panel, insulation and liner panel, it boasts efficiencies to legacy individually assembled component designs with similar attachment to the structure. However, we must address the unique properties posed by IMPs with curb solutions that maintain the integrity of the panel to accommodate roof penetrations.

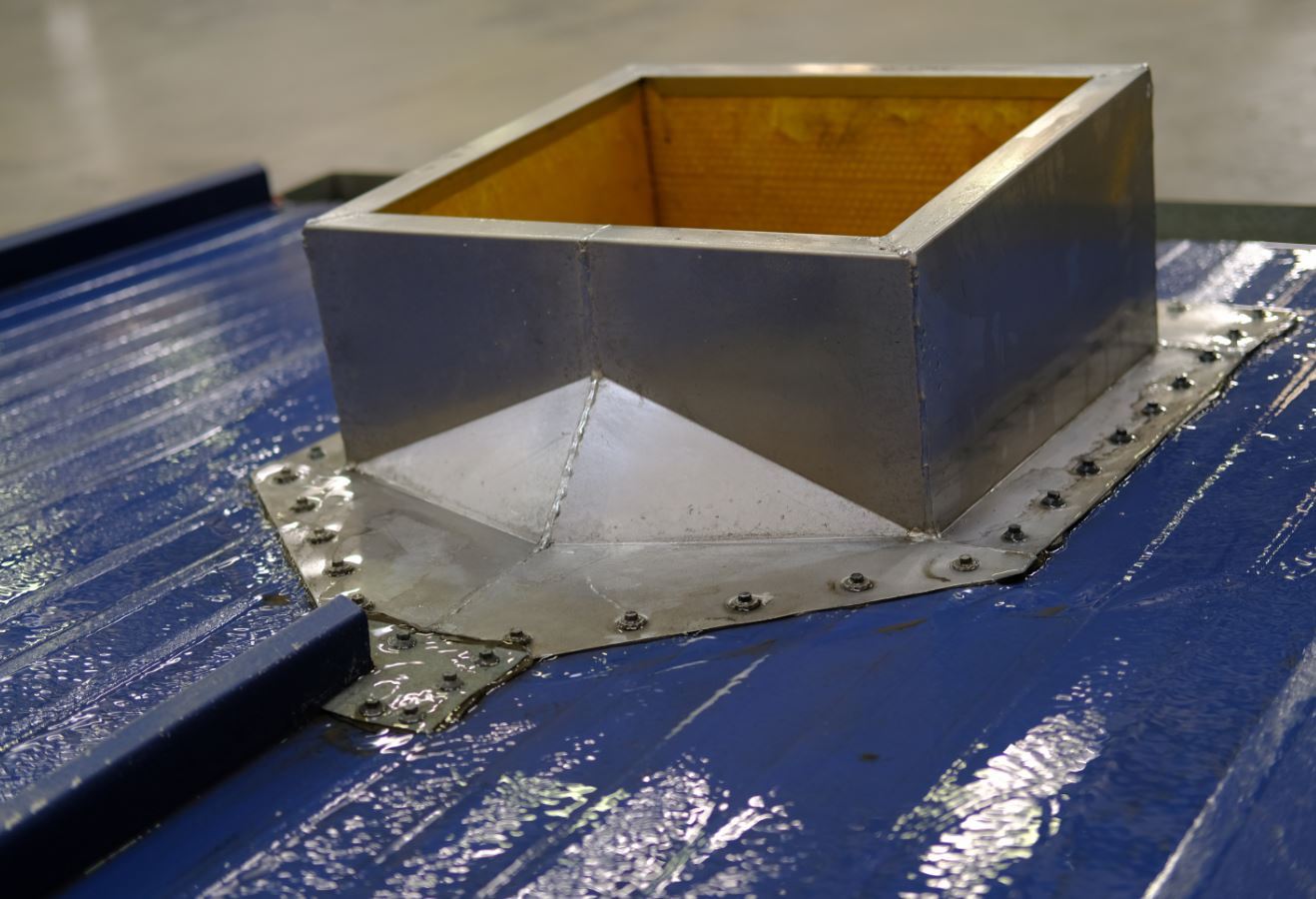

The roof curb is the most effective option for providing a transition between the roof system and the rooftop-mounted equipment in sloped and non-sloped conditions. For metal roofs, a curb is designed to integrate with the panels via flange connection details that seal the major and minor panel ribs via industry specific sealants, fasteners and closures similar to panel splice and eave termination details.

Compatible materials and hydrology are applied for determining curb minimum heights, flange dimensions, cricket size and connection placement as the prolonged exposure to precipitation and typical weather effects can rapidly degrade the spliced connections if proper curb design is not employed. On the underside, special attention should be applied to the finished appearance of the interior cladding for occupants which includes trimming the hole in the ceiling with supplemental materials or an inclusive sub-framing system from the curb manufacturer, so the insulation remains encapsulated for an appealing aesthetic.

Although an IMP is a singular component that accomplishes multiple roles for a building, it must be broken down within its layers to apply proper metal roofing fundamentals that allow a curb system to seal and support the roof penetration. For example, while the deflection of an IMP is not as severe as a trapezoidal standing seam from a live-load standpoint it will still flex when walked across and is certainly not designed to support loads imposed by rooftop equipment.

Therefore, weight transference should be applied to the secondary framing members of the roof to maintain the gasket composition of the sealed curb flange connection to the roof panel via sub-framing. Additionally, like single-skin metal roofing, all fasteners through the IMP top skin must have a backer to provide long-term compression of sealants where the water exposure occurs. By applying full perimeter support from the roof panel offset and providing a backer for fasteners, the uniform curb flange gasket that eliminates air leakage and subsequent moisture intrusion becomes a resilient layer that mimics the metal roofing fundamentals that have been vetted and employed effectively for decades.

Supplemental insulation with a higher R-value for the roof curb wall is an upgrade that corresponds well with the thermal performance of IMP; however, is not necessary in most instances. Rather, the primary focus of a curb system for this application should be reducing the size of the thermal void that is created by the roof penetration itself. Instead of adapting curbs that are designed for single-skin metal roofs that require panels to be cut all the way back to adjacent high ribs for connection, a better solution is minimizing the roof opening to match the curb opening inside dimension. This approach coupled with an effective curb subframing delivers direct load transference to the building’s secondary framing while minimizing the size of the hole created in the valuable IMP.

There is no universal roof curb to marry the abundance of rooftop equipment to buildings. However, there are specially developed curb systems that embody IMP dynamics using proven erector-friendly installation techniques to maintain the reliability of the assembly. Think about these properly vetted details and ask your supplier how they accomplish full perimeter support, panel offset, uniform gasketed connection and maximum thermal conservation when choosing roof curbs of all sizes for your next project.

Clifton Reasor is vice president of business development at Roof Curb Systems, Trenton, Ga. To learn more, email creasor@roofcurb.com or visit www.roofcurb.com[1].

- www.roofcurb.com: http://www.roofcurb.com

Source URL: https://www.metalconstructionnews.com/articles/roof-penetrations-and-insulated-metal-panels/