Sealants for Metal Roofs

by Mark Robins | 1 December 2021 12:00 am

Keeping metal panels in place with an attractive watertight seal

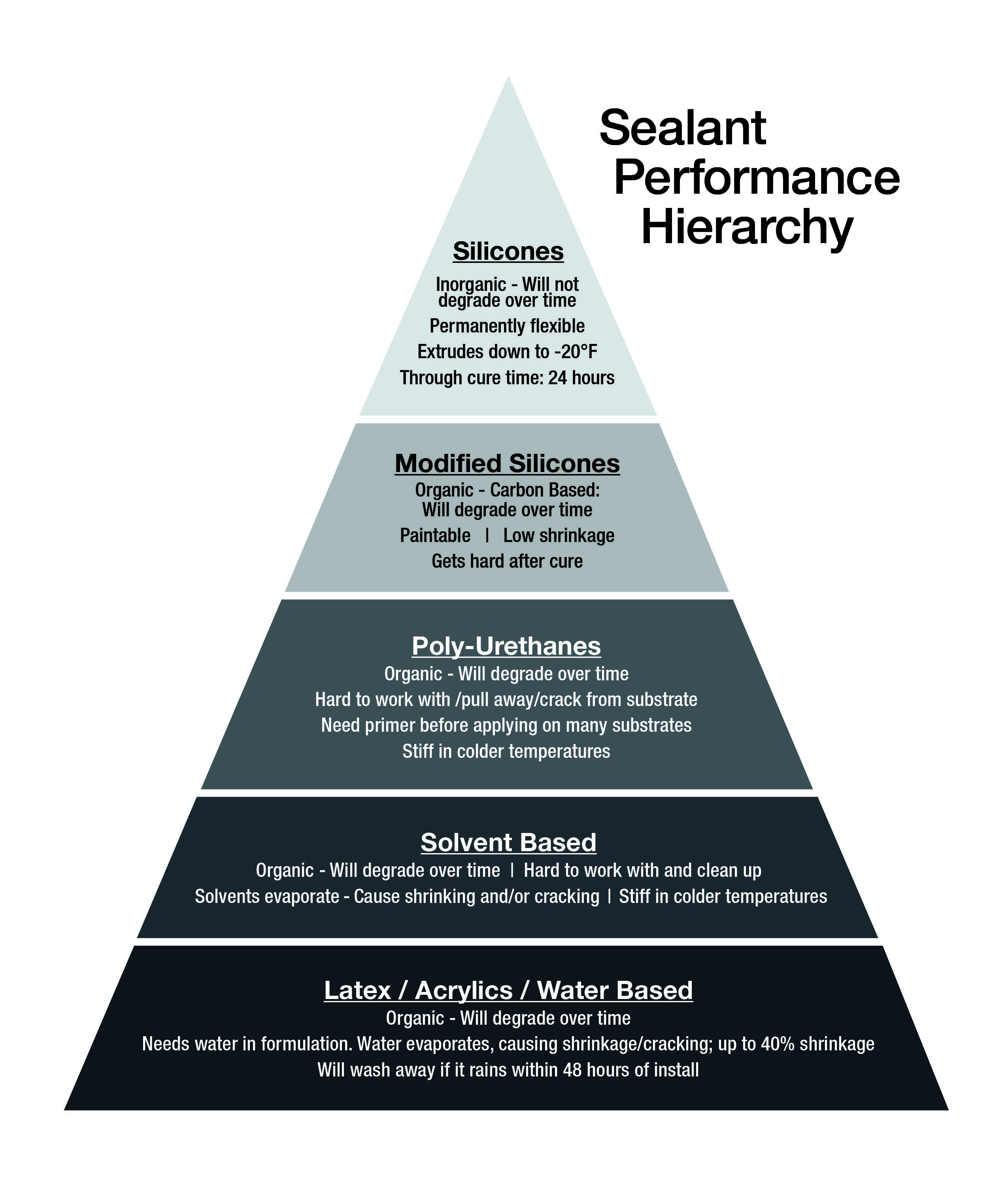

But while it’s easy for the metal panels to pull off this kind of longevity, it’s not always so easy for the sealant keeping them in place while providing an attractive, watertight seal. That’s where you need to apply some real thought. Here’s what to consider when choosing from the following five types of sealants.

Water-based Sealants

These include latex and acrylic sealants, which are great for general construction purposes requiring easy application and smooth tooling. But their formulation requires water, and what does water do? Right! It evaporates while curing. This evaporation will naturally cause the sealant to shrink. In fact, it can shrink up to 40%—to nearly half the size as when it was gunned out—which then leads to cracking.

Shrunken and cracked sealant does not add up to a long performance life, and you’re sure to get an earful about the shoddy appearance. And, if clouds are gathering during installation? Don’t even think about it! Latex and acrylics can wash away if it rains within 48 hours after application.

Solvent-based Sealants

Solvent-based sealants can offer more durability than water-based ones, though they will also encounter unwanted shrinkage and cracking due to evaporation while curing. Moreover, they are hard to work with, especially in cold weather. Each drop in degree makes the mix stiffen that much more, leading to cramps in your straining trigger fingers. Even harder is the clean-up, with sticky sealant ending up all over your hands and pants, and, often times, steering wheel and truck seat.

Polyurethane Sealants

These ultra-tough sealants certainly have their place, but it sure isn’t on your metal roof. As with a solvent-based sealant, a polyurethane one is hard to work with and stiffens in cold weather. But worse yet, they do not adhere well to metal, and will pull away. So, they require a primer, which adds an extra step and an extra expense.

Modified Silicone Sealants

These can provide added flexibility, for less shrinkage. Plus, they are paintable. Indeed, there are many fine modified silicones on the market. We even offer one called NovaBond.

But, though commonly referred to as a silicone, just get down to the molecular level and you’ll see the backbone of this category of sealant is actually urethane … with silicone caps on each end of the molecular chains. So, all scientific mumbo-jumbo aside, it’s really more of a siliconized urethane. It will still be susceptible to UV degradation and chalking.

None of the Above Can Handle the Sun Above

Apply a water-based, solvent-based, or modified-silicone to your metal roof and you’d better put down the caulk gun and pick up a paint brush. Because without a coat of paint, it will be like going without sunblock. These organic sealants are susceptible to UV light, which will break them down and cause cracking and chalking.

Want a maintenance-free metal roof? You want silicone. Nothing else offers you the longevity and appearance you need to see your warranty through to the end—and even beyond.

“But,” you may be thinking, “silicone won’t stick, right?” Wrong. Silicone will absolutely adhere properly to metal. You simply need to pick the right silicone with the right chemistry.

Don’t Pick the Wrong Silicone

If you’re looking at an acetoxy silicone, you’re looking at a silicone made of a chemical that will lower PH levels. This creates an acetic acid while curing, which can lead to acid etching of paint, creating rust lines around beads … and even deter from adhering to certain metals.

Unsure if the silicone in your gun is made of acetoxy? Just take a whiff. If the silicone stinks, so will its performance on your metal roof.

An Inorganic Oxime Silicone

This particular compound provides superior adhesion to metal. And the inorganic chemistry making up oxime silicone allows light rays to pass right through it, doing no damage. It simply won’t degrade.

That’s why we use oxime chemistry to produce our NovaFlex line of silicones. It can extrude down to -20 F and it remains permanently flexible. There is never any fading, chalking or cracking. There is one drawback: it’s not paintable. So, we offer translucent and color-matching choices.

Brad Macoubrie is the building systems national sales manager at Novagard, Cleveland. To learn more, visit www.novagard.com[1] or call (800) 380-0138.

- www.novagard.com: http://www.novagard.com

Source URL: https://www.metalconstructionnews.com/articles/sealants-for-metal-roofs/