Selecting a Code Compliant Metal Building Insulation System

by Jonathan McGaha | 31 August 2015 12:00 am

How to comply with the building envelope provisions in codes and standards

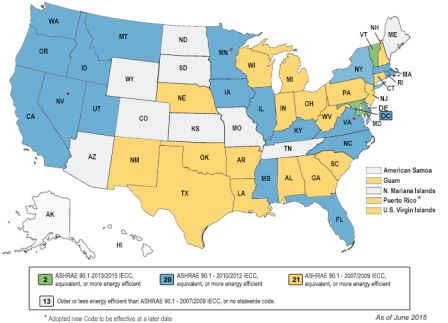

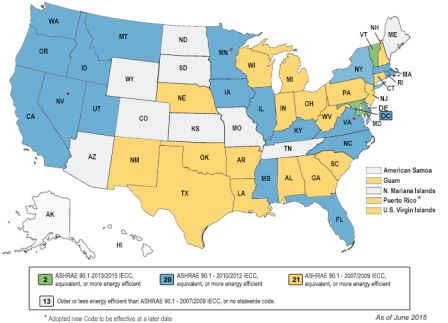

Complying with today’s energy codes requires designers and builders in the metal building industry to understand how to comply with the building envelope provisions in the International Conservation Code (IECC) and ASHRAE 90.1 energy standard.

The adoption of new, extremely efficient energy codes and standards (i.e., ASHRAE 90.1-2010/2012 IECC, or newer) has presented opportunities for the metal building community to meet and exceed building envelope provisions. Efforts are currently underway to incorporate new high R-value/low U factor metal building wall and roof insulation systems into Appendix A of the ASHRAE 90.1 Standard. In the meantime, provisions exist in the energy codes to use alternate systems, as long as a tested U-factor for the assembly can be provided.

Metal building designers and builders have a choice to use the insulation roof or wall systems prescriptively provided in the R-value tables in IECC and ASHRAE 90.1, or they may choose to use a tested system that meets or exceeds the assembly U-factors shown in a similar table. To help navigate the available interior metal building insulation options, below is a general overview:

|

| Photo courtesy of The Lamtec Corp. |

Roof Insulation

High R-value/low U-factor metal building roof insulation systems can be broken down into two generic categories: filled cavity systems (fiberglass) and rigid continuous insulation (foam). Under the filled cavity category (U-Factors of 0.037 or less), there are essentially two options:

• Long Tab Banded (LTB) System

• Liner System

Both of these systems function as the name implies; they fill the cavity between the purlins or girts with fiberglass insulation. Typically a minimum of two layers is used; one layer is installed between and parallel to the purlins, and one layer on top of and perpendicular to the purlins. In both cases the insulation is supported by a series of bands attached to the underside of the purlins. The primary differences between these two systems relate to the vapor retarder facings:

• With the Long Tab Banded System, the vapor retarder is laminated to the lower fiberglass layer and the facing tabs follow along and over the purlins, where they are sealed together to maintain the continuity of the vapor retarder.

• With the Liner System, the vapor retarder is installed separately from the insulation under the purlins and above the banding.

With the LTB, the lower purlin flanges are exposed to allow for unobstructed installation of the mechanical and electrical equipment. With the Liner System, the purlins are covered, making it necessary to cut into the vapor retarder to gain access to the structural components of the building.

Side-by-side thermal testing by an independent accredited laboratory has demonstrated comparable performance with both systems. Consult your insulation supplier for test results and supporting documentation.

Continuous insulation provides a strong, durable and attractive interior finish. It is often a preferred option for use in applications where high interior humidity is present, such as indoor swimming pools and nurseries. Continuous insulation is also commonly used in applications requiring a low interior temperature, such as cold-storage buildings.

In some cases, hybrid systems utilizing a combination of foam and fiberglass can be used to achieve required thermal performance. When considered, these systems should be reviewed with your insulation, fastener and building supplier to avoid any unintended consequences, such as condensation and/or structural issues.

When choosing continuous insulation, it is advisable to confirm the fire ratings of the products are acceptable for use by the local fire code. Depending upon the fire rating, a separate thermal barrier may or may not be required by code.

Wall Insulation

High R-value/low U-factor metal building wall insulation systems can also be broken down into two generic categories: filled cavity systems (fiberglass) and rigid continuous insulation (foam).

Several single- and double-layer fiberglass filled cavity insulation (U-factors of 0.059 or less) systems have been developed to meet the metal building wall requirements established in 2015 IECC and ASHRAE 90.1-2013. These systems include:

• Single-layer systems that use a combination of fiberglass (to fill the cavity between the girts) and foam tape (between the wall panels and girts).

• The double-layer systems are similar to the single layer systems above, but a second layer of fiberglass is installed between the outer girt flanges and the wall panels for added thermal performance. Depending upon the U-factors required, foam tape or 1-inch foam thermal blocks are also used. With these systems, U-factors as low as 0.036 can be achieved. As detailed above for the roof system, continuous foam insulation is preferred for high-temperature, high-humidity applications. The same advantages and caveats discussed for the roof also apply to the walls.

Hal Robbins is technical director of The Lamtec Corp., Mount Bethel, Pa. For more information, visit www.lamtec.com[1] or call (800) 852-6832.

- www.lamtec.com: http://www.lamtec.com

Source URL: https://www.metalconstructionnews.com/articles/selecting-a-code-compliant-metal-building-insulation-system/