The 2025 Metal Construction News Project Excellence Awards

by David Flaherty | 18 November 2025 12:09 pm

[1]

[1]Metal is a true canvas for creativity. More than 110 projects submitted for this year’s Project Excellence Awards showcased the limitless possibilities of metal design. Metal’s versatility and beauty were fully displayed from the grandest structures to the smallest details.

This year’s overall winner—from the Metal Craftsmanship category—was the MICRON Team Member Center, a purpose-built facility in Manassas, Va. In addition to our overall winner, there were five other category winners listed here:

Metal Roofing – New Construction: Potter Residence

Metal Roofing – Retrofit: Davidge Hall

Metal Walls – Retrofit: Fraser Hall

Metal Walls – New Construction: Parcel U

Metal Buildings Systems Buildings: Dobson Pipe Organ Builders

Congratulations to all our winners, who are featured in the following pages. Read on to discover why they deserve praise for their unparalleled execution and creativity in metal.

Metal Craftsmanship and Overall Winner: Micron Team Member Center

[16]

[16]The MICRON Team Member Center is a purpose-built facility to support the company’s growing workforce and foster a collaborative, people-focused culture. Its bold, modern design is defined by a sweeping curved façade clad in diamond-patterned metal panels, complemented by expansive glass walls that bring in natural light and promote transparency. Exposed timber beams add warmth and balance, while integrated landscaping and sculptural details complete the welcoming atmosphere. The building’s signature element—the curved façade wrapped in diamond-patterned panels—creates a dynamic, futuristic identity. Installed in a seamless, flowing layout, the panels reflect light throughout the day, producing ever-changing textures and shadows across the exterior. More than an aesthetic feature, they showcase precision fabrication and durability, underscoring MICRON’s commitment to innovation and cutting-edge design.

In the MICRON Team Member Center, stainless steel panels are used as part of the building’s exterior cladding. These panels create a modern, polished appearance while providing durability, corrosion resistance, and low maintenance. Their reflective surface enhances the building’s visual impact, catching light and highlighting the curved, flowing design of the façade. Functionally, they also help protect the structure from weather and environmental wear while contributing to the building’s overall sleek and high-tech aesthetic.

Stainless steel was selected for the MICRON Team Member Center because it combines durability, low maintenance, and aesthetic appeal. Its strength and corrosion resistance make it ideal for exterior cladding that withstands weather and environmental exposure. Additionally, metal allows for precision fabrication, enabling the building’s curved, flowing, and diamond-patterned façade to be executed accurately. Aesthetically, stainless steel’s reflective, modern surface enhances the building’s contemporary design, complements the glass and timber elements, and conveys a sense of innovation and craftsmanship aligned with the project’s vision.

The project involved extensive use of metal wall panels from two manufacturers: IMETCO supplied 1,208 m2 (13,000 sf) of stainless steel panels, and Morin Co. provided 1,765 m2 (19,000 sf) of profile panels. Beyond the metal work, the project’s scope also encompassed a comprehensive glazing package, including the installation of curtain walls, skylights, storefronts, all glass entrances, and mirrors.

Micron Team Member Center, Manassas, Va.

Total area: 3,716 m2 (40,000 sf)

Building owner: Micron Technology, Inc.

Architect: Jacobs

General Contractor: Whiting-Turner

Metal installer: Eastern Glass and Aluminum, Inc

Manufacturers: Morin Co. / IMETCO

Metal Building Systems Buildings:

Dobson Pipe Organ Builders

[17]

[17]A devastating fire displaced Dobson Pipe Organ Builders from their shops and offices on June 15, 2021. The fire precipitously changed the texture of the square in the small community. The replacement was intended to represent the craft of organ building, not just a metal building.

The structure is predominantly a shop and storage space, so the principal programmatic requirements were high ceilings and flexible, open space. However, the program seemed at odds with the town square site and the intended narrative of craft, and the budget was not flexible. The narrative needed to be written with fewer words, such as a haiku, a typical structure with limited words to give meaning in just three lines.

Contrary to the original beliefs regarding epitomes of craft, the building is grounded in a standard metal frame placed on a uniform grid, which is line #1, which is foremost economical. The scale is inherently larger than anything else on the square, because most neighboring buildings come from a past that had a different scale. The mass is quieted with the color black. It recedes and remains quiet despite the unfamiliar size.

The next entry is line #2. The corner entry ties the building to the square with the reaching canopy and the material unique to the palette. The wood of the canopy is akin to the “case” of an organ. It is the focus of much detail in the design and building of an organ and is unique to this instrument.

The final line is the erecting room, which does not fit within the standard frame. The height needs to match those spaces found in cathedrals. The towering volume represents the pipes in the narrative, and the color is a familiar silver shimmer of tin and lead. Three lines that fit a small town. It is just a metal building.

Metal was used throughout the building, both structurally and aesthetically, to support the specialized work of organ pipe erection. The constants of the pre-engineered metal building resolve simple requirements of high clear space and open planning, unencumbered by columns. The building’s framework is constructed from metal to ensure durability and the ability to support the large, intricate equipment and materials involved in the organ-making process. Metal is also incorporated in the exterior finishes, reflecting the abstract forms and themes of the pipe organs themselves. The metallic surfaces, inspired by the pipes, create a visual connection between the architecture and the craftsmanship of organ building. The choice of metal ensures functionality and longevity and complements the building’s design concept, enhancing the overall resonance between form, material, and purpose.

Metal was selected for this project due to its economy, durability, and resonance with the purpose of the building. As a space dedicated to creating pipe organs, the material choice reflects organ construction’s functional demands and artistic vision. The material’s structural integrity ensures the building can support the large-scale equipment and delicate components required for the work, while also offering an aesthetic alignment with the abstract interpretations of sound and form inherent in organ building. The metallic surfaces echo the pipes of the organs themselves, enhancing the thematic connection between the building’s architecture and function. Metal’s modern appeal and adaptability make it an ideal choice to reflect the innovative, yet historically rooted, nature of the work done within.

The project utilized products from Chief Buildings, specifically their pre-engineered metal building (PEMB) components. The exterior metal cladding consisted of CS/AP panels, and the roof system utilized MSC panels, a type of standing seam metal roof panel. The total amount of products used included a PEMB footprint of 1,384 m² (14,893 sq sf), cladding covering 1,474 m² (15,862 sf), and roof panels covering 1,484 m² (15,973 sf).

Dobson Pipe Organ Builders, Lake City, Iowa

Total area: 1,486 m2 (15,998 sf)

Building owner: Dobson Pipe Organ Builders

Architect: ASK Studio

General Contractor: Badding Construction

Metal Installer: OG Steel

Manufacturer: Chief Buildings

Metal Roofing (New Construction): Potter Residence

[18]

[18]Nestled in a small clearing within a rugged 40-acre parcel in the Huasna Valley, the Potter Residence exercises compact design and physical restraint. This 139 m2 (1,500 sf) three-bedroom and two-bath private residence was envisioned as a permanent rural home for a young couple and their two small children. The client insisted that the new home be distilled to a handful of essential spaces needed for compact living. As avid outdoor enthusiasts, the family would spend 90 percent of their time exploring their vast property, so the house was to serve as a “base camp” even though this project would be their primary residence. And to ensure this new project would not fall victim to scope creep, the client chose to construct this project as owner-builder, obviating the need and expense of a general contractor. The result is a modest yet bespoke home that echoes the very ethos of the client, while respecting the site and landscape.

Durable material choices such as standing seam metal roofing and exposed concrete floors echo the client’s modern sensibilities, while creating a domicile that can withstand the rigors of the family’s two rambunctious children, as well as provide resiliency against increasingly hostile weather and fire conditions so prevalent in California. Metal panels are used exclusively as exterior cladding and comprise most of the exterior walls and roof. These thin, seamless panels form a permeable boundary for the family to transition indoors and outdoors while offering protection from the elements. Able to withstand harsh conditions, the residence provides the family with a place of rest in a location prime for engaging with their expansive property.

In the Potter Residence, metal created a distinct yet complementary boundary with the natural surroundings. Combined with a small amount of natural wood siding, the residence effectively embodies its connection to the outdoors while maintaining a distinct separation between the two. This simple, yet robust material palette reflects the minimalist lifestyle of the clients while alluding to their passion for adventure. The residence is nestled in a clearing within their extensive property, serving as a stable front for the family. Metal panels act as a shield, offering shelter while integrating the family within the site. The uniform finish allows for minimal upkeep, ensuring the family can enjoy the outdoors to the maximum.

The project incorporated 441 m² (4,750 sq sf) of M-COR corrugated soffit/wall panels, which were supplied by McElroy Metals.

These panels were 24-gauge metal, featuring a Matte Black color and protected by a Kynar factory finish. The panels were initially 559 mm (22 in.) wide, factory corrugated, and were cut to the necessary length on-site for installation on both the walls and roofing of the structure.

Potter Residence, Huasna Valley, Calif.

Total area: 139 m2 (1,500 sf)

Building owner: Private owner

Architect: garcia architecture + design

General Contractor: Owner

Manufacturer: McElroy Metal

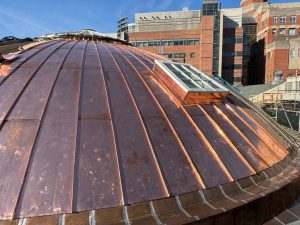

Metal Roofing (Retrofit): Davidge Hall

[19]

[19]Davidge Hall, formerly the College of Medicine of Maryland, is on the University of Maryland’s Baltimore campus. Built in 1812, Davidge Hall is listed on the National Register of Historic Buildings and is the oldest medical school building in the Western Hemisphere. The hall contains offices, museum artifacts, a conference room, and two amphitheaters with surrounding galleries. Architecturally, it features a circular dome shape, three stories of heavy timber and steel, and red-brick walls. Davidge Hall is an incredibly significant cultural and historical landmark; therefore, it was vital to restore the building while retaining as many original features as possible. The Durable Slate Company removed the cypress wood shingle roof on the dome and gable. It installed a new 567-g (20-oz) standing seam copper roof, replicating the original to retain historical accuracy. They also removed and replaced the concealed copper gutters at the eave lines of the dome and gable roofs and installed new soldered copper flashing and curbs at the skylights on the gable roof. The damaged sheathing was replaced as well.

The unique design of the building, including the curved dome and the tiered radius gutter system, proved to be a substantial challenge for the team. Early in the project, the crew lost three out of four of its experienced sheet metal mechanics. The remaining sheet metal expert and five apprentices were left to complete this incredibly complex project on their own. Therefore, Durable Slate utilized in-house training to teach apprentices the proper soldering technique and in-the-field training for applying the solder and copper panels. Through Durable’s intensive training program and the extensive talent of the team, the restoration of Davidge Hall proved to be a highly successful endeavor.

The building’s distinctive dome was likely clad initially in copper, but it was re-roofed with wood shakes at some point. This decision, while well-intentioned and seemingly “historic,” was not true to the building’s original design intent. Therefore, working with The Christman Company, The Durable Slate Company returned the dome to copper cladding using a 567-g (20-oz) standing seam roof, restoring its historic appearance and long-term durability. It serves as a reminder that buildings evolve, and sometimes preservation means undoing past alterations. Respecting history is not just about preserving the past, but also ensuring that what remains accurately tells the story.

Copper was chosen for this project mainly because it provides resistance against adverse weather conditions, allowing Davidge Hall to withstand the elements for years. The new copper roof is a replica of the original, preserving the structure’s historical value while enhancing its durability and giving it an updated appearance. Copper roofs also require little maintenance, further expanding the building’s lifespan.

The project involved the installation of approximately 6,000 sf of 567 g (20 oz.) copper, as well as Lead Free Johnson Solder for joining, and WIP 300 HT underlayment to provide a protective layer underneath the copper roofing. The materials were sourced from several manufacturers, including Velux, Heather & Little, and Revere Copper.

Davidge Hall, Baltimore

Total area: 492 m2 (5,300 sf)

Building Owner: University of Maryland, Baltimore

Architect: JMT (Johnson, Mirmiran, & Thompson, Inc.) Architecture

General Contractor: The Christman Company

Metal Installer: The Durable Slate Company

Manufacturer: Velux / Heather & Little / Revere Copper

Metal Walls (Retrofit): Fraser Hall

[20]

[20]The University of Minnesota – Twin Cities recently completed upgrades to its nearly 100-year-old Fraser Hall. This $132 million project consolidated various chemistry disciplines across several halls into one central chemistry building for undergraduate-level courses. With the renovations, Fraser Hall now features 18 new interactive laboratories, modern study method equipment upgrades, collaboration spaces, faculty offices, and general-purpose chemistry classrooms. Fraser Hall has approximately 10,870 m² (117,000 sq sf) of space and will serve as the central science building for more than 5,000 University of Michigan students annually.

The metal used creates a versatile, shiny, adaptable facade that could be color-matched and work for various application needs. The three main areas where metal was used had different goals, and this material could meet all of them, whether it was penthouse enclosure panels, curved and perforated fins that doubled as sunshades, or a facade that stood out like a penny.

Metal was used for this project due to its adaptability, not just for the variety of desired applications, but also for its long-term adaptability and changeability. Metal was used throughout the building for many interior and exterior applications, making it durable and versatile. The main appeal, though, was for the properties of copper itself. Today, the raw copper is shiny and striking all on its own, but over time, the raw metal will beautifully oxidize and patina into a gorgeous, classic green known as verdigris.

The team custom-fabricated 1,450 m2 (15,607 sf) of (16 oz.) copper panels with personalized embossing and a natural copper finish. Each panel was pressed into a specially designed stamp to achieve a ribbed profile and then fabricated into the S-Slip panel system for the main façade. Vertical blade attachments were used to affix more than 93 m2 (1,000 sf) of .080” aluminum sunshade fins directly into the glass curtain wall. The fins feature a curved profile with perforations and a copper anodized finish. The penthouse on the top of the building features several systems, including 730 m2 (7,853 sf) of Pac Clad’s 24-gauge snap-on batten standing seam panels and 169 m2 (1,820 sf) of louvers from Construction Specialties Louvers. An additional 232 m2 (2,500 sf) of aluminum flush-seam panels were fabricated and installed at the soffits, entrance overhangs, and parapet walls in a custom Fraser Gray finish. The interior features 139 m² (1,500 sq sf) of Fraser Grey finished plate panels in the entryway.

Fraser Hall, Minneapolis

Total area: 10,670 m2 (117,000 sf)

Building owner: University of Minnesota

Architect: BWBR Architects (Executive Architect)/VJAA Architects (Lead Design Architect)

General Contractor: Mortenson Construction

Metal Installer and Manufacturer: MG McGrath, Inc.

Finishes: Linetec

Curtainwall: EFCO

Metal Roofing (New Construction): Parcel U

[21]

[21]Parcel U stands as a study in contrast, where natural materials and industrial aesthetics converge to create something bold, grounded, and forward-thinking. Working closely with Jacobs as Executive Architects and Ennead Architects as Design Architects, Pure + FreeForm helped create a façade that merges timeless material qualities with cutting-edge performance. The panels showcase two bespoke finishes, a terracotta-inspired tone and a warm rust patina that echo natural materials while offering modern performance. Paired with authentic terracotta at the building’s entrance, the metal cladding creates a refined, cohesive facade that balances authenticity and innovation. Fabricated from highly recyclable aluminum with at least 20 percent post-consumer content, the panels are engineered for UV resistance, durability, and low maintenance. This innovative, sustainable system supports Parcel U’s LEED Platinum certification while addressing the aesthetic and functional demands of an urban life science setting.

To meet the project’s sustainability and performance goals, Pure + FreeForm provided a metal panel system that offers both environmental responsibility and practical advantages over traditional materials. Their durable finishes resist UV degradation, fading, and environmental wear, ensuring long-term visual and structural integrity with minimal maintenance. Compared to full terracotta cladding, the panels are significantly lighter and more cost-effective, reducing structural demands and simplifying installation while making them an ideal solution for high-performance façades.

Pure + FreeForm played a key role in shaping Parcel U’s distinctive façade by developing custom metal panels that visually reflect the terracotta and rust tones featured at the building’s entry. These panels, finished in two unique earth-inspired hues, were crafted to capture the richness of natural materials while integrating seamlessly with the building’s sculptural pilasters. Beyond aesthetics, the panels are engineered for resilience to resist UV exposure, fading, and environmental wear over time. Their lightweight aluminum construction offers a practical alternative to complete terracotta cladding, easing installation, reducing structural load, and requiring little to no maintenance, all while preserving the visual depth and warmth of the original material.

The project utilized a total of 7,019 m2 (75,547 sf) of custom-fabricated aluminum metal panels from the manufacturer Pure + FreeForm.

Specifically, the materials included two variations of the Pure + FreeForm aluminum metal panel in a Baguette profile: one featuring a custom terracotta finish and the other featuring a custom rust finish. Both panel types were 3 mm (0.12 in.) thick and consisted of single-skin aluminum.

Parcel U, Boston

Building Owner: DivcoWest

Architect: Executive Architect: Jacobs / Design Architect: Ennead Architects

General Contractor: John Moriarty & Associates

Metal installer(s): Ipswich Bay Glass Company

Manufacturer: Pure + FreeForm

A Heartfelt Thank You

Metal Construction News would like to thank our four judges for their time and dedication in evaluating these submissions. With a wealth of experience and industry knowledge, these experts had no trouble selecting our winning projects.

James C. Tuschall Sr., President and CEO, Tuschall Engineering Company Inc.

The company has been in business for 87 years, and James has been there full-time for 50 years, plus a few part-time years while in school. He served more than a decade with the Metal Construction Association, including nine years on the board, and has been a member of the Sheet Metal Workers Union, Local 265, for 50 years.

Isaac Bracher, Architect, OPN Architects

Throughout his professional career, Isaac has assembled a diverse portfolio of award-winning projects, ranging from small, carefully crafted residential interiors to large, higher-education campus facilities. He also brings extensive experience in furniture design and construction to each of his projects. This knowledge has enhanced his sensitivity for detailing on a small scale, which he applies to larger and more complex projects. In 2013, the Ball State College of Architecture and Planning Alumni Society Board of Directors recognized Isaac as a recipient of its annual Award of Outstanding Achievement.

Robert Tiffin, National Accounts Manager, Silvercote

Robert Tiffin’s passion for creating positive changes motivates him daily. The metal building systems industry is evolving, and Tiffin actively creates opportunities to forge a new perception by thinking well beyond the conventional “pre-engineered metal box.” As the national accounts manager of Silvercote—a laminator in custom insulation solutions—Tiffin leads foundation customer relationships in the United States and Canada.

Art Hance, President, Hance Construction Inc.

Art Hance is the founder and president of Hance Construction, Inc., headquartered in Warren County, N.J. Hance served as president of the Metal Building Contractors and Erectors Association (MBCEA), where he was instrumental in driving the creation of the nation’s first accreditation program for metal building contractors, IAS AC-478.

Marc Singer, Director, Strategic Marketing, BlueScope Buildings North America

Marc Singer is the Director of Strategic Marketing for BlueScope Buildings North America, overseeing BlueScope’s buildings brand portfolio – Butler Manufacturing and Varco Pruden. With a career spanning top global brands, Marc has crafted award-winning campaigns for McDonald’s, Budweiser, and Skittles, and driven transformative sales and marketing efforts at Herman Miller and MillerKnoll.

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757533515-8533.png

- 2024 Winners: https://www.metalconstructionnews.com/articles/the-2024-metal-construction-news-project-excellence-awards/

- 2023 Winners: https://www.metalconstructionnews.com/articles/the-2023-mcn-project-excellence-awards/

- 2022 Winners: https://www.metalconstructionnews.com/articles/the-2022-mcn-project-excellence-awards/

- 2021 Winners: https://www.metalconstructionnews.com/articles/the-2021-metal-construction-project-excellence-awards

- 2020 Winners: https://www.metalconstructionnews.com/articles/the-2020-metal-construction-news-building-roofing-awards

- 2019 Winners: https://www.metalconstructionnews.com/articles/the-2019-metal-construction-news-building-roofing-awards

- 2018 Winners: https://www.metalconstructionnews.com/articles/the-2018-metal-construction-news-building-roofing-awards

- 2017 Winners: https://www.metalconstructionnews.com/articles/2017-metal-construction-news-building-and-roofing-awards

- 2016 Winners: https://www.metalconstructionnews.com/articles/2016-mcn-building-roofing-awards

- 2015 Winners: https://www.metalconstructionnews.com/articles/2015-mcn-building-roofing-awards

- 2014 Winners: https://www.metalconstructionnews.com/articles/2014-mcn-building-and-roofing-awards

- 2013 Winners: https://www.metalconstructionnews.com/articles/2013-mcn-building-and-roofing-awards

- 2012 Winners: https://www.metalconstructionnews.com/articles/2012-building-and-roofing-award-winners

- 2011 Winners: https://www.metalconstructionnews.com/articles/2011-mcn-building-and-roofing-awards

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757533479-4643.png

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757714153-8939.jpeg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757024859-8138.jpeg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757710016-4949.jpeg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757016196-2666.jpeg

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2025/11/1757001296-7496.jpeg

Source URL: https://www.metalconstructionnews.com/articles/the-2025-metal-construction-news-project-excellence-awards/