Today’s Aluminum Extrusions

by Mark Robins | 1 May 2020 12:00 am

Creating unique solutions and providing greater value

Maybe you’ve also worked with interior products that incorporate extrusion such as

railing systems, interior partitions, etc. There’s good reason for this. Aluminum extrusions provide the product designer and architect with:

• Versatility and flexibility: There is a huge range of finish options, the ability to create complex forms, to tailor thermal performance and create aesthetics that range from historic to ultra-modern.

• Outstanding performance: Extrusions’ lightweight and high strength-to-weight ratio make them ideal for supporting the large glass lites that are so popular today, with minimal impact on sight lines. That strength, along with aluminum’s natural corrosion resistance and opportunities for warranted finish, means that performance will be maintained over time, unlike some alternative materials.

• Safe and sustainable: Aluminum extrusions are free of toxic material and are noncombustible. Further, they are infinitely recyclable and can be produced with high levels of recycled content to meet customer environmental concerns.

• Proven: Though an 1883 technical paper suggested aluminum as “the metal of the future,” it was in the 1930s that aluminum was first prominently used in construction, in New York City’s Empire State Building. Since then, aluminum and aluminum extrusion has been increasingly significant for both contemporary projects and historic renovation. A fun fact, while the spandrel panels in the Empire State were aluminum, the initial window framing was steel; all 5,460 of those windows were replaced with extrusion-framed units 25 years ago as part of a major energy efficiency initiative.

Component Solutions

Despite a lengthy history, extrusions are staying contemporary, with continuous advances in design and thermal performance. A new version of ASHRAE 90.1 (ASHRAE 90.1-2019), the Energy Standard for Buildings has just been released.

Over the past 15 years (since ASHRAE 90.1-2004) advances in energy codes have reduced potential building energy use by over 35% by prescribing more energy-efficient glass and framing. With improved thermal break technology from both fill-and-debridge and insulbar suppliers, aluminum extrusion-framed windows have continued to meet and exceed the new code. A new round of improved thermal management is currently being introduced.

Custom Options

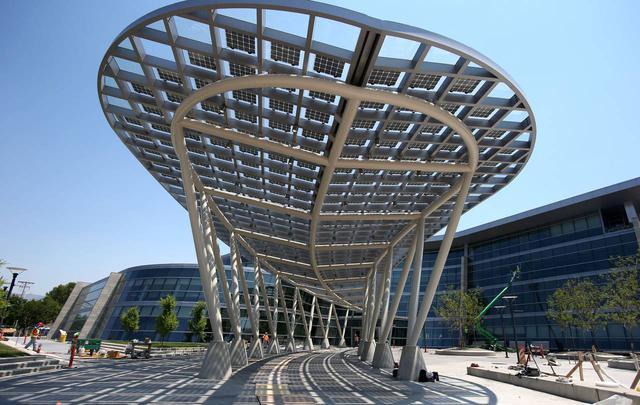

In addition to high-performance extrusion-based building components available from systems providers, the extrusion process provides contractors and installers the option to create custom building elements. For instance, a project with a custom entry canopy could make a distinctive architectural statement. A unique façade treatment could enhance a customer’s branding. A custom railing design, sunshade or open stair riser could enhance the overall environment. Extrusion allows creation and execution of these custom elements quickly and at relatively low cost.

Custom Elements

Most likely, the first question is whether a custom design is feasible based on project budget and timeline considerations. Tooling for extrusions is among the least expensive of all manufacturing processes. Simple extrusion dies are often less than $1000, and dies for more complex designs are generally less than $5000. Dies can be produced and trialed in three to four weeks.

Compare that with rollform tooling, which can take over three months, and cost over $30,000 per shape. The low cost/quick turnaround for extrusion tooling facilitates prototype development, or production in the case that prototypes are either machined from readily available standard aluminum shapes or created via 3-D printing.

Equally significant is the availability of expertise that can assist in achieving a successful custom process. While there are multiple references that discuss extrusion design, there is no better approach than working hand-in-hand with a local extruder who knows how to execute a custom design.

In the U.S. and Canada there are about 130 aluminum extruders, operating in roughly 200 locations across 38 states and provinces. Certainly not all have the equipment and expertise needed for success in building applications, but many do. Extruders prefer to get involved early and use their process experience to help customers realize their design concepts in the most cost-efficient and timely manner

Lynn Brown, AEC Market Development, Aluminum Extruders Council (AEC), Wauconda, Ill. To learn more, call (847) 526-2010 or visit www.aec.org[1].

- www.aec.org: http://www.aec.org

Source URL: https://www.metalconstructionnews.com/articles/todays-aluminum-extrusions/