Using 3-D Imaging to Increase Profits from Design to Installation

by Jonathan McGaha | 2 February 2015 12:00 am

Accurate, fast measurements prevent mistakes and rework

Accurate, fast measurements prevent mistakes and rework

If there is one thing that every installer knows, it is that no structure is built exactly according to the plans. Walls are not perfectly plumb, floors are not level and distances fl oat. While this is sometimes due to errors by those performing the construction, it is also a simple fact that the tolerances required for metal architecture systems often exceed those maintained by other construction disciplines.

This is especially problematic for those installing metal façades and canopies. These systems are often the final items to be installed so they are subjected to the aggregated errors of all of the work that is completed prior to their installation. To make matters worse, most of the slack in the schedule has been used by the time this phase of construction begins so there is little time left for any mistakes-even those caused by others.

To meet these compressed schedules, the materials have to be made in advance, and as a result, the construction drawings are often used to design the custom metal components. When the actual construction differs from the plans shown on the drawings, problems can bring installation to a halt. The solution, of course, is to have accurate drawings of the structure as-built as opposed to as-designed. Designers, fabricators and installers are finding that nothing accomplishes this faster and more accurately than 3-D imaging systems.

These systems digitize environments the way that office scanners copy a piece of paper and save it as a JPEG or a PDF fi le. While there are multiple types of 3-D imaging systems, the most commonly used systems in architectural environments are static laser scanners. Laser scanners are basically a surveyor’s total station on steroids. Instead of collecting a few points that denote the location of a few known assets, laser scanners capture hundreds of millions of points that cover every visible surface in the scene.

This is an important distinction versus traditional methods of verifying design. The field operators do not need to know every dimension that the fabricator might need. They simply capture the entire scene so that the designer/fabricator can dimension it as needed from his desktop. This allows for greater accuracy through repeatability and removes typical problems associated with field measurements such as tape sag, difficult to reach assets and missed dimensions. Another advantage is speed. Each scan takes between five and 15 minutes depending upon the environment. As a result, most building envelopes can be captured in less than a day.

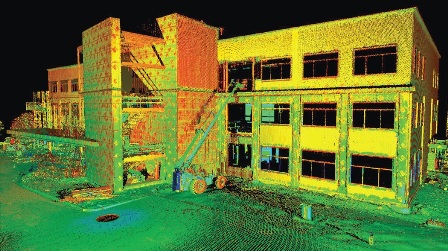

So, what type of data do laser scanners produce? Essentially the same positional data you would expect from a survey device: X, Y and Z values plus an intensity value, which provides information about how much of the laser energy bounced off of the scanned object and returned to the scanner. This can be very helpful in distinguishing between various types of material. Brick makes a different color than the metal window trim, for instance.

Each collected point contains every one of these values

(X,Y,Z,i) and most commercial scanners collect between 100,000 and 1 million points per second. The resulting dataset is referred to as a “point cloud.” Some scanners also have cameras onboard so that color information is also collected (R,G,B). This gives the point cloud a photorealistic look.

Traditionally, specialty software was needed to work with point cloud data. However, both Autodesk and Bentley have incorporated point cloud engines into their software suites over the past year. If your CAD department purchases suites such as Autodesk’s Building Design Suite or AutoCAD Design Suite then you already have the software needed to work with point cloud data. Best of all, it only requires your operators to learn a new ribbon instead of an entirely new application.

One early convert to 3-D imaging was TFC Canopy, a designer, fabricator and installer of aluminum panels in Garrett, Ind. In fact, its experience using laser scanners over the past five years to capture the as-built conditions was so successful that it bought its own scanner and began performing the service in-house. Today, it continues to do so except in cases where sending its own personnel would be cost prohibitive versus outsourcing the data collection.

Either way, TFC Canopy depends upon the point cloud data to verify that its designs will work as well with the actual building façade as it does with the design model. “The biggest benefit is on complex shapes and radius cuts, but overall we have been able to reduce our re-cuts by half since we started using laser scanners,” says Jeremy Patterson, marketing director, TFC Canopy. Less material waste, less waste of time during installation and a superior product as a result of higher accuracy fitting -what’s not to like?

# # #

Sam Billingsley is vice president of business and product development for SmartGeoMetrics, Houston. For more information, go to www. smartgeometrics.com[1] or contact Billingsley at sbillingsley@smartgeometrics.com[2].

- www. smartgeometrics.com: http://www.%20smartgeometrics.com

- sbillingsley@smartgeometrics.com: mailto:sbillingsley@smartgeometrics.com

Source URL: https://www.metalconstructionnews.com/articles/using-3-d-imaging-to-increase-profits-from-design-to-installation/