Why Ice Damming is a Thermal Failure (Not Just a Leak)

by David Flaherty | 20 February 2026 11:57 am

[1]

[1]For facility managers in the Midwest industrial corridor, winter is the ultimate stress test. But while most maintenance teams focus on visible snow accumulation, the real damage to large-scale metal distribution centers often goes unnoticed until it is too late.

In auditing performance data across 1.2 million sf of industrial roofing this past year, our team identified a recurring trend: Post-storm moisture intrusion is frequently misdiagnosed. Facility managers often treat water ingress as a simple “leak” caused by weather, when it is usually a symptom of internal heat loss, specifically, ice damming.

In low-slope metal retrofits, ignoring the physics behind these dams does not just lead to wet floors; it also results in denied insurance claims, structural stress, and massive operational disruption. To protect the assets, stop treating the water and start treating the heat.

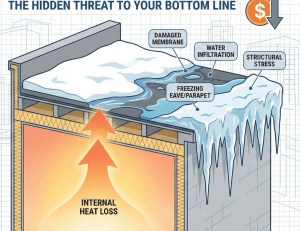

The anatomy of a commercial ice dam

Contrary to popular belief, ice dams on commercial properties are rarely caused by storms. They are a thermodynamic failure of the building envelope.

The cycle begins inside the facility. In many older industrial buildings, heat generated by manufacturing processes or heating systems escapes through the roof deck. When heavy snow covers the roof, it acts as an insulating blanket, trapping that escaping heat against the roof surface.

This trapped heat melts the bottom layer of the snowpack, even when outside temperatures are well below freezing. This meltwater trickles down the metal roof’s slope until it reaches the eave or parapet wall. Since these outer edges extend past the heated interior of the building, they are significantly colder.

The result? The water refreezes instantly upon contact with the cold eave, forming a solid ridge of ice. As the cycle continues—heat escapes, snow melts, and water runs down—that ridge grows into a dam. Eventually, the meltwater has nowhere to go. It pools behind the dam, backing up under the membrane and flashing, or saturating the insulation assembly.

This dynamic is particularly aggressive on metal assets. Unlike single-ply membranes over ISO board, metal has high thermal conductivity. If the underlying insulation is compressed, wet, or insufficient (as is common in buildings aged 20-plus years), the metal panel transfers interior heat to the snowpack efficiently. This creates a rapid melt cycle that can overwhelm standard drainage systems, turning a manageable snowfall into a critical ice event within hours.

The B2B Cost: Why this kills NOIs

For an industrial tenant or owner, the cost of an ice dam extends far beyond the price of a roof patch. It attacks the net operating income (NOI) of the facility in four specific ways:

- Operational disruption: In a “just-in-time” manufacturing environment, water on the floor means stopped production lines. Facilities lose thousands of dollars per hour in downtime due to “nuisance leaks” that were actually unchecked thermal dams.

- Safety and liability: As the dam grows, it often pushes outward, creating massive icicles or unstable ice sheets around the building perimeter. This creates immediate slip-and-fall liability for workers and dock logistics crews loading trucks.

- Insurance denial: This is the most critical risk. Many commercial policies cover “storm damage” but have specific exclusions for damage caused by “maintenance neglect” or “gradual deterioration.” If an adjuster determines that the water intrusion was caused by long-term thermal inefficiencies that were never addressed, the claim for that saturated insulation may be denied.

- Energy hemorrhaging: An ice dam is physical proof that owners are paying to heat the outdoors. That escaping heat represents a significant monthly utility loss. By upgrading the thermal envelope to stop ice dams, our clients often see a secondary return on investment (ROI) in reduced HVAC loads during the winter months.

The solution: Flute-fill and thermal breaks

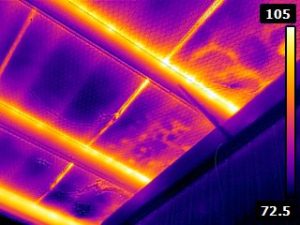

[2]

[2]Solving ice damming requires a “envelope first” mindset. The ice cannot simply be scraped away; the heat must be stopped from escaping.

In metal retrofits, the most effective defense is to eliminate the thermal bridge. This is typically achieved through a flute-fill system. By installing custom-cut insulation into the valleys (flutes) of the existing metal roof before installing the new single-ply membrane, a consistent thermal barrier is created.

Many facility managers attempt to solve this with “active prevention” methods alone, such as zig-zagging heat cables (heat trace) along the eaves. While heat trace can help keep gutters flowing, it is ultimately a band-aid. When relying on electric cables to melt ice, it is only fighting the symptoms. The only way to cure the “disease” is to address the R-value deficit. The heat must be stopped from reaching the snow in the first place.

Increasing the R-value of the roof assembly keeps the heat inside the building where it belongs. If the roof deck stays cold, the bottom layer of snow does not melt, the water does not run, and the dam never forms.

Winter is a systems test

As the freeze/thaw season deepens, facility managers should look up. Stained ceiling tiles near exterior walls are not just leaks; they are red flags for thermal failure. By addressing the root cause—heat loss—it protects not just the roof, but the entire operation underneath it.

Brandi Van Wambeke is a commercial solutions specialist at Exceptional Roofing, serving the industrial and commercial sectors across the seven-state Mid-South and Midwest region. She specializes in metal retrofit strategies that help facility executives reduce OpEx liability and improve structural longevity

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2026/02/Figure-1-Ice-Dam-Anatomy.png

- [Image]: https://www.metalconstructionnews.com/wp-content/uploads/2026/02/FLIR3348.jpg

Source URL: https://www.metalconstructionnews.com/articles/why-ice-damming-is-a-thermal-failure-not-just-a-leak/