Institutional Longevity: Zinc and copper roofs are long-term solutions for two projects

by Jonathan McGaha | 31 May 2010 12:00 am

When Rice University, Houston, decided to put 60,000 square feet (5,574 m2) of new roofs on its Duncan and McMurtry College dorm buildings, it required something that would last a very long time that also had a very distinct look. As an institutional facility, it didn’t want a roof that would have to be replaced in 10 to 20 years.

When Rice University, Houston, decided to put 60,000 square feet (5,574 m2) of new roofs on its Duncan and McMurtry College dorm buildings, it required something that would last a very long time that also had a very distinct look. As an institutional facility, it didn’t want a roof that would have to be replaced in 10 to 20 years.

At the Texas State University Nursing Facility in Round Rock, Texas, it was a similar situation. The intent was a long-term solution.

The answer for the two facilities was in two types of metals that are still less than commonplace in the United States, despite some major advantages. The zinc that was chosen for Rice and the copper roof at the Texas State nursing facility, are meant to last for what may seem like forever.

“When I say long term, I mean for the remainder of the century,” said Brian Selig, project manager for Houston-based Architectural Building Components, which manufactured the roof products on both projects. “Properly installed zinc and copper roofs have been around for 100 years, some longer.”

Why Go to Europe When You Can Stay in Texas?

That’s essentially the question Architectural Building Components asked when the architects on the Rice University project wanted to go with a European company they were familiar with. After some convincing, Rice got American harvested zinc on its job.

“We thought [that] was a pretty big deal,” Selig said. “We were able to match the [pre-weathered] appearance [they were seeking] and give them a local manufacturer which probably saved them some money.”

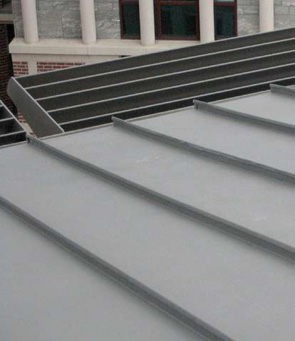

Architectural Building Components’ DuraZinc 200DL panel—made exclusively from zinc—was used on both college buildings, and the uncertainty of lead times when having a product delivered from overseas was taken out of the equation. A thick plastisol coating was applied to the back of the panels to keep moisture from contacting them. There is also a space between the roof deck and the panel to allow airflow to occur. According to Selig, constant contact with water is the Kryptonite to zinc, as well as copper, and you have to make sure moisture won’t linger on these products.

Architectural Building Components’ DuraZinc 200DL panel—made exclusively from zinc—was used on both college buildings, and the uncertainty of lead times when having a product delivered from overseas was taken out of the equation. A thick plastisol coating was applied to the back of the panels to keep moisture from contacting them. There is also a space between the roof deck and the panel to allow airflow to occur. According to Selig, constant contact with water is the Kryptonite to zinc, as well as copper, and you have to make sure moisture won’t linger on these products.

The $36 million, 78,000-square-foot (7,246-m2) Texas State University Nursing Facility project will house numerous clinical practice and simulation labs, state-of-the-art medical equipment and manikins, a variety of classrooms and seminar rooms, administration and faculty office space, and an auditorium and lecture hall. The facility’s Copper 200 Double Lock roof was also elevated off the deck, and stainless-steel clips prevented any corrosion issues from dissimilar metals. The clips allowed for the more intense thermal movement of copper, as well.

“They wanted copper right from the beginning, we didn’t talk them into it,” Selig said. “This is another institutional situation. They were intent on providing a long-term solution up there in the roof.”

Wearing Well

Wearing Well

The durability and longevity of zinc and copper comes with a price, of course. Copper prices, in particular, are very volatile, so the price can actually change somewhat dramatically from when the planning begins to when the materials are ordered. So when the budget is there, the job must be done right—the products have to be of high quality and well tested, and the installation needs to be carefully monitored.

“With both of these projects the challenge is these are very expensive materials,” Selig acknowledged. “So setting a high standard and thinking about all possible variables that could affect the life of these materials is really important.”

Selig said that too frequently with metal roofs, the reason they have to be replaced is not because of a poor system, but a poor installation.

“Too many decision makers look at metal roofs as a decoration, they don’t consider it as a watertight application for roofing and mainly because of the misapplication they’ve experienced or heard about over the years,” Selig said.

Installed properly, however, the premium you pay up front for zinc and copper can pay off over its life when you consider the total cost of ownership. Zinc and copper don’t suffer the wear and tear from rain, because they patina, with copper turning bronze and then green over time, and zinc turning silver to dark gray.

On both the Rice and Texas State projects, Architectural Building Components did extensive testing for water infiltration and wind uplift. According to Selig, because of the softness of copper, without the proper impact resistance testing, a bad hail storm might have created a situation where the whole roof would have to be taken off.

The Texas State copper roof also came with a 20-year weathertight warranty.

“We provided all the details and drawings for installation and made multiple visits out to the job to make sure the installer was putting the materials in properly,” Selig said.

Both copper and zinc can contribute some to LEED because of their recycled content and recyclability, however their main sustainability benefit—and consequently cost benefit—seem to simply be longevity. A quality zinc or copper roof can last for a century.

Coming to America?

Coming to America?

The question remains: If zinc and copper roofs are so durable, why don’t you see more of them in the U.S.? In Europe, they’re very common. Part of it is likely just a style choice, part of it is price, but it may also be a different outlook on the life of a project.

“When I look at our market here and when you talk to architects,” Selig explained, “they say [buildings are] built here to be replaced more so than other places. I had an architect tell me they build the schools with a 20-year life on them because they anticipate in 20 years the conditions will be different. They may have different needs. So why use a roof system that has a life that’s far longer than that? We have a different philosophy about building around here.

“For example, we’ve got some state-of-the-art stadiums in this country and they look beautiful right now, but what is their place in society in 40 years?”

In the case of Rice and Texas State, they’re institutions looking to spend money for the long haul, so the material choices made sense. Selig said you also see copper, zinc and stainless steel being used in more caustic environments where perhaps some other materials would not last, however for typical educational or medical facilities, the momentum in the U.S. has yet to build.

On the Rice University Duncan and McMurtry Colleges, Houston-based Linbeck was the general contractor; Sir Michael Hopkins of Hopkins Architects (USA), London, served as design architect; Hanbury Evans Wright Vlattas + Co., Norfolk, Va., served as executive architect; and Marton Roofing, Houston, was the roofing contractor for the project.

On the Texas State University Nursing Facility, Port Enterprises Ltd., Manchaca, Texas, was the copper roof installer; Barnes, Gromatzky, Kosarek Architects Inc., Austin, Texas, was the architect; Richter, Cornbrooks, Gribble Architects Inc., Baltimore, was the associate architect; and Flintco Inc., Tulsa, Olka., was the construction manager.

Source URL: https://www.metalconstructionnews.com/products/institutional-longevity-zinc-and-copper-roofs-are-long-term-solutions-for-two-projects/