A brake is a metalworking machine that bends sheet metal into precise angles and shapes. It forms these predetermined bends by clamping the metal between an upper punch tool and a bottom vee-slot die, and then exerting a vertical force upon it. The punch’s profile determines the bend radius and the stroke depth determines the bend angle.

Advantages and instructions of a portable metal press brake

The main advantage of a portable metal brake is it lets contractors form custom pieces of metal right on the job site. (Photo courtesy of Van Mark Products Corp.)

Press brakes have many options and can be adjusted to create a variety of bends and angles. Brakes can be small, manual, portable devices for job-site applications, or computerized, hydraulic machines suitable for large steel sheets made during production. This article focuses on portable hand brakes for bending metal on job sites.

In metal construction, brakes bend metal pieces that form tightly to the structural frame. A portable brake can work almost anywhere on a job site—even on a truck tailgate—for a variety of fabricating tasks from large HVAC transitions to narrow roof flashing to material as small as 4 inches. Other applications include drip edges, trim, gutters, copings, soffit panels and J-channels.

On-Site Advantage

The main advantage of a portable metal brake is it lets contractors form custom pieces of metal right on the job site. “Many times, the actual size of a metal shape needed and what is on the blueprint of drawing differ,” says Gary Weinert, director of sales and marketing,Van Mark Products Corp., Farmington Hills, Mich. “A portable brake allows the contractor to custom make the exact sizes needed on-site when they are needed. If a pre-bent piece of metal does not fit the area required, then an additional pre-bent piece needs to be ordered and either picked up or delivered. Ordering pre-bent pieces typically costs more per piece but it may also slightly reduce the labor factor. These are decisions that ultimately need to be made by the foreman or owner of the company doing the installation based on what best fits their needs.”

Weinert asserts that many of his customers started out with a shop brake and pre-bent all their trim prior to going to the job site or purchased their pre-bent pieces from a metal supplier. Many of them wrongly thought this was their only option and they were left with a large margin for error. While an on-site press brake may not completely replace a shop brake or a supplier of pre-bent shapes, it lets contractors customize required pieces onsite.

“From a monetary point of view, the cost of a [portable] brake should be compared with the potential lost time and labor costs while trying to run back and forth to a shop or supplier to have the correct size pieces made to complete the job. Contractors typically find that the relatively small investment in a brake versus the money lost on labor, lost time and not being able to make custom trim pieces typically makes [a portable] brake a common-sense investment.”

The MAX-I-MUM II Brake offers commercial-grade, onsite metal bending and weighs just 133 pounds for easy one-man transport. (Photo courtesy of Tapco Tools)

Bending Preparation

Assemble the brake only according to manufacturers’ instructions; improper assembly can create hazards. Because of the weight of the brake and stand, two people are sometimes required to assist in the assembly and installation. Use a portable metal brake safely only in an unobstructed work area that is clean and well‑lit. Sheet metal can come in large sheets, is sharp and requires room to maneuver. Move anything that is in way so workers don’t trip over it.

Inspect the brake’s general condition before every use. Check for loose hardware, misalignment or binding of moving parts, cracked or broken parts, and any other condition that may affect its safe operation.

Place the brake on a sturdy surface that will not tip over, such as a workbench, pickup truck tailgate, or its leg supports, if it has them. This flat, stable surface must support the weight of the metal brake, the metal being bent and the bending force. A brake’s weight capacity and other product capabilities apply only after it is correctly and completely assembled. Keep fingers clear of the frame and upper press plate. A brake can quickly crush or amputate fingers, hands or body parts. Always chamfer and de-burr sharp sheet metal edges before bending as sharp edges on sheet metal can result in severe cuts.

Bending Operation

Once the brake is ready and the metal’s flat stock or coil stock is available, make accurate markings based on the measurements of the areas to bend first. This minimizes having to handle the sheet metal too many times moving it in and out of the brake. A dry erase marker won’t leave an unwanted mark you won’t be able to clean off the metal. To see if the markings are accurate, make a test bend on a scrap metal part so a good metal sheet isn’t ruined. Once the markings are complete and accurate, make any necessary cuts to the sheet metal. Once the bends are made—in most cases—it is practically impossible to make these cuts without damaging the metal.

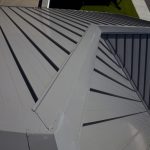

These metal panels were bent on-site to account for walls, valleys and other offsets. Above the dormers, smaller and larger panels were made to accommodate the structure. (Photo courtesy of Albert’s Specialty Roofing)

Then, using the measurements of the pieces needed, bend them out of the flat or coil stock. “To bend on a Van Mark brake, you simply open the brake, position the metal in the jaws of the brake, close the brake and bend to the desired angles,” Weinert says. “For multiple angles, simply repeat the steps until you have your custom-bent metal pieces.”

It may become necessary to adjust the position of the upper press plate to accommodate a thicker or thinner piece of sheet metal. Don’t tighten the clamp that holds the metal too much or the metal could get dinged or damaged. Set the clamp handle with enough pressure so the metal can’t be moved by hand. Also, clamps can wear down and may need to be replaced. They should be periodically removed by their screws and inspected. If there are signs of wear such as scratches, chips or just overall worn-down areas, then they should be replaced. New clamps can be reattached to the frame with a screwdriver or a small hand drill.

After using a metal press brake on-site, wipe its clamping fingers, clamping base, bending blocks and other external surfaces with a clean cloth to clear away any metal debris. Periodically lubricate all moving parts and surface with a light oil. Cover the metal brake when not in use.

Bending Limitations

Know your portable job-site brake’s limitations: the length and the throat depth. Do not exceed the maximum bending width capacities of the metal stock for the brake. “Van Mark brakes are available in various sizes from 2 feet long to 14 feet long, 6 inches long, with the most common size sold being 10 feet, 6- inches long,” Weinert says. “Van Mark brakes are available in both 14-inch throat depth and 20-inch throat depths to fit the end users’ needs.

The gauge and tensile strength, and metal coating certainly affect a brake’s bending capacities.” Also, do not exceed the portable brake’s listed weight capacity and be aware of dynamic loading. Sudden load movement may briefly create excess load causing product failure.

In terms of errors, Weinert says the biggest mistakes he sees bending metal is when the metal is used that is past a brake’s capacity. “Typically, this will not damage the brake—unless the warning signs of damage are ignored—but will result in the metal not bending to the same angle throughout the entire bend. We always encourage contractors and our distributors to send us the manufacturer’s specifications for the metal and we can advise if our tools have the capacity to bend and cut those materials. We have technical team members available to help advise which of our tools best fit that person’s needs. The second most common mistake is not double checking the measurements prior to bending. The old adage ‘measure twice, bend once’ applies here.”

(Photo courtesy of Van Mark Products Corp.)