Fasteners that secure metal roof panels come in a multitude of sizes, shapes, materials and coatings. To ensure that roofing contractors use the right fasteners for the job, Metal Construction News asked manufacturers what they recommend for specific applications.

Pick the right fastener for a metal roof installation and you’ll avoid future problems

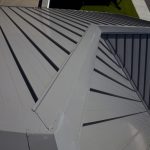

The type of fastener used in a metal roof installation depends on the panel material, the substrate, and the corrosiveness of the environment. (Photos Courtesy of Lakeside Construction Fasteners)

This article references single-skin and insulated metal panel (IMP) systems, including standing seam and stone-coated metal roofs. Also provided are tips for avoiding roof leaks and prolonged maintenance that may result from poorly installed fasteners.

Metal roof panels may be installed with exposed or concealed fastener systems. The panel manufacturer’s designs inherently determine the type of fastener system used. Concealed-fastener systems are generally more expensive, says Ed Lash, product manager for Atlas Bolt & Screw Co., Ashland, Ohio.

The type of fastener depends on the type of metal panel as well as the substrate below the panel. A metal roof can be made of steel, aluminum, copper or zinc, and the substrate can be metal or wood.

“For a wood substrate, roofing installers would use wood screws,” says Lash. “For a steel-frame building, in most instances self-drilling screws are used. For some applications over rigid insulation, special screws with gaps in the threads are used.”

Wood substrates can be pine, fir, oak, CDX, plywood or OSB. Velliquette says #12 or #14 fasteners are recommended because the threads are spaced even further apart than the #10s, helping them engage the coarser wood fibers found in manufactured wood materials.

When attaching a single-skin metal roof panel to a metal substrate, there are a variety of fastener options, says Jerod Webber, sales manager with Dynamic Fastener, Kansas City, Mo. “Several head styles or configurations are available to accommodate a wide range of applications, with the most common being a hex washer head (HWH) with a separate bonded EPDM sealing washer, or a cup style head where the sealing washer is more of a standalone but is designed to fit under the integrated washer face,” says Webber. A washer made of EPDM, or synthetic rubber, will prevent water intrusion.

Fasteners with T-1 drill points are used for panel-to-panel connections or “stitching.” (Photo Courtesy of Lakeside Construction Fasteners)

Fasteners are differentiated by diameter and length as well as drill point. “When attaching to a purlin, a T-3 point is generally used, although T-4 and T-5 points are available for attaching to heavier material,” he says. “Fasteners with T-1 drill points are used for panel-to-panel connections or ‘stitching.’”

Premium head styles such as zinc cast head or stainless cap screws offer greater corrosion resistance, says Webber. Also available are 410 stainless steel or bi-metal fasteners if corrosion resistance is desired for the entire fastener, not just the head. Webber recommends a bi-metal fastener coated with Dynamic’s Dyna- Coat 1,000-hour salt spray premium coating for corrosion resistance.

Metal substrates require fasteners with threads that are closer together in order to anchor the metal panel into the purlin, Velliquette says. These can be 5/16 to 3/8 HWH with a sealing washer system, such as a flat bonded or tubular washer. The fastener shank can range from a #12 up to a 1/4 diameter, which will reduce the chances of the fastener failing in high torque or shear conditions.

A self-drilling fastener has a point and a notched tip that acts as a drill bit, enabling it to tap its own pilot holes through the metal panel. This in turn allows the fastener threads to anchor themselves and prevent failure from pull-out/pull-over conditions. For this type of fastener, drill points ranging from T-1 to T-5 are required depending on the thickness of the steel substrate.

IMPs, which have insulating foam cores sandwiched between metal skins, tend to use longer self-drilling fasteners because the panels may vary in thickness depending on the application. The panels are typically attached to a metal substrate, preferably one that installers won’t have to pre-drill in order to accommodate the fasteners. Velliquette says the head height (hex or low profile) is important because the fasteners are concealed.

“You don’t want the hex head to prevent the IMPs from interlocking with each other during the installation process,” he says.

Different fasteners are used for residential and commercial roofing, Velliquette says, “We’re starting to see more home builders switch from the traditional asphalt shingle roof to metal roof systems that really didn’t exist 20 years ago.”

Most residential roofing is installed over a wood frame or plywood sheathing, so wood screws are typically used, with sealing washers if it’s an exposed-fastener system, says Lash. In a concealed-fastener system, a pancake-head wood screw is utilized to fasten down the clips.

Low-profile 3/4 AG Panels—metal roof panels with 3/4-inch ribs—are one type of metal roof system used in residential applications. AG Panels are secured with an exposed fastener known as a through fastener, where the head is exposed with a sealing washer and the threads pass through the metal panel into the substrate to secure it in place. This type of metal roof, however, is being installed less often nowadays because standing seam and stone-coated metal roofs have become so popular with homebuyers.

The fasteners for a standing seam metal roof are concealed underneath the metal panel in a clip system that holds the panel in place and is anchored into a wood substrate. They typically have an internal drive system and a flat profile so that the fastener heads don’t protrude below the metal panels after installation. (An internal drive is a shaped cavity inside the fastener head that allows torque to be applied.)

Stone-coated metal roofs also utilize concealed fasteners that don’t require a washer and can have a higher hex head. Depending on the fastener pattern, the roof may or may not be installed over battens instead of solid decking. This type of roof is regularly specified for higher-end homes, especially in coastal areas, says Velliquette.

As standing seam and stone-coated metal roofs become more affordable, roofers will start favoring concealed fasteners with internal drive systems, he adds.

According to Webber, fasteners with a Type A or Type 17 point are typically used in metal roofs on commercial buildings that have a wood substrate. Commercial roofs tend to have a higher rib-panel profile than residential—1 1/2 inches or higher. Stone-coated metal roofing is also used in commercial applications, which are usually metal-to-metal and require #12 (diameter) self-drilling fasteners, Velliquette says.

Consider the Environment

Fastener selection is also impacted by the environmental conditions to which the metal will be exposed. These include wind-driven elements like rain, snow and dust; heavier snow loads; high-wind zones; and high-heat conditions. When the correct fasteners are used, they’ll keep the metal panels from pulling away from the substrate.

“The type of roofing material and substrate plays a large role in the features engineered into a fastener, such as the shaft and thread diameter and length, the thread pattern, the type of point, the diameter of the fastener head features, the shape of the head, and the material the fastener is made from, whether it’s stainless steel, carbon steel, or hardened steel,” says Robert Shirley, product marketing manager for Simpson Strong-Tie, Pleasanton, Calif.

For steel roofing, Simpson Strong-Tie recommends large-head, medium-head or self-drilling metal screws. For concealed fastening in a standing seam metal roof, clip screws are recommended. The clip screws are designed with drill points for cutting into metal, and metal tapping threads for securing metal-to-metal connections.

In coastal locations, says Velliquette, roofing crews should use fasteners that are either stainless or rated as long-life fasteners, where the exposed heads are guaranteed not to develop red rust over the life of the metal panel.

“When Hurricane Irma went through Naples, Fla., it tore metal panels off buildings,” he says. “But it wasn’t the panels that failed; it was the carbon fasteners, which were used in an environment producing salt spray that accelerated their oxidation and made them weaker.” He recognizes that as the environment continues to change, it will be critical for manufacturers to develop fasteners with plating systems that prohibit oxidation. In situations where they will be concealed, pancake-head fasteners are considered the most effective, especially for standing seam metal roofs. Low-profile, pancake-head fasteners are also effective for clipless or nail-hem panels that are attached directly to the roof deck. The low-profile head is less likely to dimple the panel covering the fastened side of the preceding panel when installed.