Installing metal wall panels on a metal building system may seem like a simple task for installers, and most of the time it is. However, for insulated metal panels (IMPs), the proper structural alignment of the metal building is imperative for a smooth and attractive installation, as well as long-term performance.

Improper building alignment can lead to poor panel performance

Insulated metal panels being installed on a project. (Photo courtesy of Metl-Span)

If the alignment of a metal building system isn’t perfect when installing single-skin through-fastened metal panels, it often doesn’t become much of an issue since the panels are flexible and can bend a bit to provide a clean installation. However, this is not the case when installing IMPs.

Arnold Corbin, technical sales manager at Lewisville, Texas-based Metl-Span, says there are two main considerations when it comes to a metal building systems structural alignment for installing IMPs: installation difficulty and product performance. “Put another way, insulated metal panels installed on a building that is poorly aligned create a much greater risk of the product not performing properly over the long haul,” he says. “In fact, the product can even buckle.”

Al Detmer, field technician services manager at Kingspan Insulated Panels, Deland, Fla., concurs, saying the structural alignment of a metal building is crucial for the performance of the entire building. “A building out of alignment can cause issues not only with the panels, but also with any type of penetration such as windows, doors or louvers,” he says. “If the building is not square and all the fastening members are out of the manufacturer’s specification, it is difficult for the panel installation crew and the other contractors to keep their installation in alignment so all the products work together and perform as intended.”

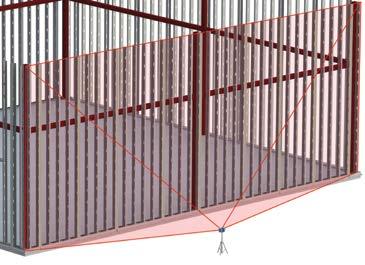

An example of a 3-D laser scan to check the structural framing alignment. (Photo courtesy of Metl-Span)

Proper Installation Requires Inline Steel Framing

Before installing IMPs, it is important to check that the wall framing is straight and in alignment so that all wall panels can be installed without encountering problems. If the steel framing is out of the manufacturer’s specifications, Detmer notes that several issues can occur. These include stress on the foam panel causing rippling, known as oil canning; engagement of the next panel becomes difficult; and the loss of a proper seal at the joints where the butyl sealant and the lip of the panel do not get a proper engagement. Additionally, Detmer adds, “Crushing of the leading edge of the panel where the clip and fasteners are installed can happen when the contractor overdrives the fasteners to pull the panel to the steel. This can cause an aesthetic issue at the joint and possibly cause blistering of the panels in that area.”

“To achieve a proper installation, the steel erector is responsible for the proper adjustment of all the steel so the steel framing will be inline to one another,” Detmer says. “The building needs to be square.”

As Ken Buchinger at Houston-based MBCI explains, if a foam panel is fastened to structural members that aren’t in proper alignment, you will end up bowing the panel and its tongue-and-groove joinery where the panels go together, not allowing the next panel to be installed correctly. “The groove of the previous panel is going to be crooked where the girt is in or out,” he says, “and the panel you’re putting up there is nice and straight, you won’t be able to fit it in if the panel is bowed.”

Effects of Thermal Stress

If the framing is not within tolerance, Corbin notes that it can be difficult to engage the panel joint and maintain module. “The product performance can be affected since structural alignment is one of the key variables concerning how the panel reacts to thermal stress.”

Since IMPs are a composite panel made up of two metal skins bonded to a core, thermal stress can happen when one side of the panel is warmer than the other. “Unlike single-skin panels that react to heating by expanding, insulated metal panels—due to the composite make up—react by bowing,” Corbin explains. “As one face is heated by the sun or exterior temperatures, the inside face remains at a constant temperature. The panel will bow to the warm side.”

“If there is an inward or concave bow in the panel from misalignment, this can create a wrinkling of the panel face,” Corbin continues. “It can even contribute to core shear or face buckling. If the panels bow excessively outward or not uniformly, this can negatively impact appearance.”

There is always a certain amount of bowing between the attachment points on a panel when it heats up during the day. “If you’ve got girts 5 feet apart on the wall of a building, that 5-foot span of panel will have a little bit of a bow in it,” Buchinger says. “The exterior skin of the panel, when it heats up, always wants to bow out. If a panel has been forced in due to a girt that’s 1/8-inch, or more compared to the girt above and below it, the panel will attempt to bow out when it heats up. But if it’s already bowed in, the panel can literally buckle at some point. This is called stress buckling.” At that point, all you can do is take the panels down, straighten the structure to provide proper alignment and then reinstall the panels.

Avoid inward misalignment and shim as necessary (Left). Minor outward alignment is allowable (Right). (Photo courtesy of Metl-Span)

Methods and Solutions

When training installers, Detmer says the first thing he recommends is to go to the job during the steel erection and make sure the steel is going up correctly. “Specifically, this can be achieved by using different methods such as a laser or pulling dry lines. They should also make sure in the preinstallation meetings that the general contractor and the architect understand the importance of the steel being installed with the panel manufacturer’s specifications in mind.”

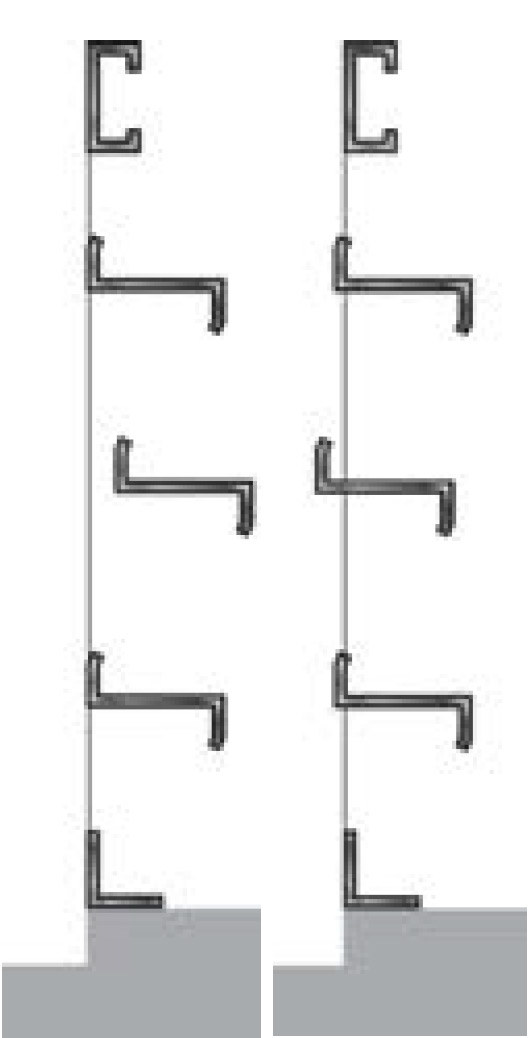

In some cases, Corbin says loosening the bolted connections of a girt may address the issue. However, if the framing is fixed and cannot be adjusted, such as with steel studs, then shims should be used. Shims can be used to address misalignments up to 1/4-inch. However, if the misalignment exceeds 1/4-inch, Corbin says a continuous shim should be used, or the framing should be adjusted.

Other solutions include using a plum bob or string line to check for framing alignment. “If the contractors are installing architectural flat or near flat panels, a laser should be used,” Corbin notes. “In large or complex projects, it is not uncommon for the framing to be scanned using a laser.”

“It’s also important to note that if the framing installation is not in a contractor’s scope of work and that contractor starts installing panels on badly misaligned framing, it is assumed that the contractor has accepted the condition,” Corbin adds.

Verify, Verify, Verify

Since not all metal building erectors have experience with installing IMPs, it’s important to always check with the IMP manufacturers on required tolerances. “Different manufacturers have different tolerances,” Buchinger says. “But the key is the tighter the girt spacing, the tighter the tolerance. Every manufacturer typically publishes its tolerances for the framework.”

Be sure to check the framework to make sure it’s within tolerance before you start installing the panels. And make sure the panels are sealed properly, otherwise it can create issue with vapor drive, which can cause issues with condensation. “As you’re installing, make sure to seal the panels to the structure, following the details explicitly,” Buchinger adds. “Put caulk where it’s required. Make sure it’s a big enough bead that you have a continuous seal, and every panel should be sealed to the structure, and with the tongue-and-groove joinery, each panel is sealed to itself.”

When adding trim pieces, Buchinger recommends making sure to follow the manufacturer details whether you’re using caulk or tape sealants. “You want to make sure everything’s fully sealed. You may have to fasten things closer together to get complete compression across the trim piece. Make sure that the tape sealant or caulk is fully compressed and sealed, ensuring the trim and the panels are sealed together, or the trim to the trim.”

A shim installed between the framing and insulated metal panel. (Photo courtesy of Metl-Span)

Contractor Responsibility

When a building starts off out of square, with the girts out of alignment, or any other issues with the steel framing, Detmer notes that everyone who must install a product to the framing will have issues which will cost extra time and labor to correct. In regards to IMPs, once they are attached to the steel framing, the panel contractor is responsible for the performance and aesthetics of the panels, so the time spent inspecting the steel before installation is valuable time well spent.

“It is always best to address framing issues before you start installation by communicating the requirements to the general contractor and framing installer along with verifying prior to starting,” Corbin explains. “Plastic shims are inexpensive and easy to install. Replacing panels is a much more expensive and expansive prospect.”

“In addition to great aesthetics, properly installed IMPs on a substructure that is properly aligned will provide years of high performance,” notes Buchinger. “They provide all three control layers required: high R-value for temperature control, a water barrier and vapor barrier.”