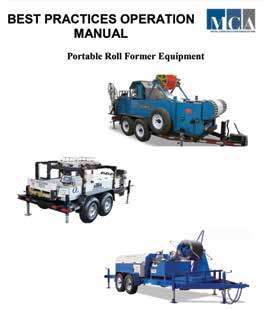

Portable rollformers give contractors the ability to form 50-foot-long panels on-site. Roof and wall panels can be formed to fit site conditions precisely. Plus, contractors have more control of when and how materials are delivered to job sites, which can be critical for some projects.

To get the most from a portable rollformer, inspection, cleanliness and lubrication are crucial

Photo courtesy of MRB Contractors

To reap the most rewards from a portable rollformer, contractors take on the responsibility of properly maintaining equipment on an ongoing basis. From industry experts, here are four keys to successfully maintaining portable rollformers.

Inspect, Inspect, Inspect

Central to upkeep of a portable rollformer is awareness of the machine. Close inspection of components before and after operation helps ensure reliable production. It can also allow for proactive maintenance. Maintaining machines with lots of visual inspections and addressing maintenance issues as quickly as possible save contractors time and money in the long run.

Ben Bradley, service manager at Denver-based New Tech Machinery Corp., services portable rollformers and trains operators. “Obviously lack of maintenance can turn into a nightmare, where a machine doesn’t work,” he says.

If you don’t see it, you won’t know to fix it, Bradley says. For portable rollformers that run with hydraulics, “you take the covers off on the hydraulic side, you want to look at the hoses and fittings. Make sure you’re not seeing any small leaks, because small leaks will turn into big leaks eventually. On the electrical side, you want to take a look at your cabling that’s run through the machine and make sure you’re not seeing any abnormal wear and tear from rubbing against something while you’re traveling down the road. For the mechanics of the machine, the big thing is inspecting the drive system.”

Photo courtesy of MRB Contractors

Likewise, Larry Chandonnet, president at Cidan Machinery Inc. in Peachtree City, Ga., tells operators to wipe their machines down before and after a job while looking for maintenance issues. “You might see a bolt being loose while you’re wiping down, you might see some buildup on the rollers, so you have to clean them. You might see some slugs caught up by the rollers, so you want to remove those. They bounce around on the trailer, and they can get caught up in a roller. Your in-feed guides might be skewed, and you want to be able to adjust them back. When you wipe down, you’re seeing these things. If you just look at your machine, you’re just not going to see everything all the time.”

Similarly, when Ken McLauchlan, director of sales at Louisville, Ky.-based Drexel Metals Inc.’s office in Arvada, Colo., trains operators, he also emphasizes visual inspections. “The words that I use all the time are trailer hitch to tail light,” he says. “So, I want you to start at the front or the back, go whichever direction you want, but I want you to walk and visually check, making sure your trailer hitch, where your ball is going to go, isn’t dry, making sure that your brake controller is attached, and that it’s charged. Look at the machine and make sure you’re not missing covers, you’re not missing screws. And if you’re missing screws, did they fall into the machine? Make sure that you check the oil in the gas motor on the back, check your hydraulic oil to make sure it’s adequate. When you come bring it back in [the shop], I would do the exact same thing in reverse, make sure your tail lights are still functioning and all.”

To catch cutoff metal from a portable rollformer, Michael Leighton, metal shop foreman at MRB Contractors, cuts a short panel and puts it under the cutting dies. Photo courtesy of MRB Contractors.

Cleanliness Is Critical

Inspecting and cleaning a portable rollformer are often done at the same time, and both help keep a machine running correctly, producing properly formed panels.

Two critical areas to clean are drive rollers and forming rollers, Bradley says. “These machines are on job sites; they’re dusty, they’re dirty. Any type of debris or any dust or dirt that gets on the forming rollers, if it’s in a place where it’s going to touch the material that goes through the forming roller, it’s going to imprint that every time that roller rotates into the panel, and that’s going to be a defect in your end product. So that’s why you want to keep the forming rollers nice and clean.”

One way to clean the drive rollers is with a citrus-based degreaser like Simple Green, or a mild soap and water solution, and a rag, Bradley says.

Another problem that can occur relative to cleanliness is dust or dirt can make its way inside the bearings of forming rollers and freeze them up, which can deform panels, McLauchlan says. He says one way to clean out debris from inside the bearings of forming rollers is using a hot water pressure washer, such as a Hotsy, on low pressure. “You don’t want to push the water directly into the bearing, but you’re trying to just basically move the debris,” he explains.

Another cleanliness issue can occur when running galvanized material, Chandonnet says. “It’s just galvanized on the outside, and sometimes it’ll just flake off and stick to the rollers. You might get a buildup on the rollers, and you’ll want to use a degalvanizing spray like Galv-Off to clean the rollers off. You want to be able to clean that because if you’re going to do colored material on the next job, you don’t want to have that galvanized on there.”

Another issue relative to cleanliness that can occur is a buildup of plastic film from coil on the forming rollers, says Eric Walund, director of operations at MRB Contractors LLC in Irving, Texas. The plastic film is a protective cover for the coil. It’s sticky and can buildup on the rollers. When that happens, there’s no elegant solution, Walund says. “You basically just kind of dig it out. You can take the rollers off and basically you just got to peel it out, pull it out, use little picks and stuff like that to get it out. You use a screwdriver or something that’s not going to damage the rollformers, and you pick it out, use a pair of needle nose pliers, you pull it out with your fingers, you just kind of get it out as best you can.”

One way to avoid the plastic film buildup is to order coil without plastic at the edges of the coil, Walund says. But that’s not always an option because not all manufacturers offer coil in that way, and sometimes the coil you get isn’t perfect, he says. “You’ll say, keep [the plastic film] off 1 inch on each edge, and it’ll be 1/4-inch off one edge and 1 3/4-inch off the other edge. So it’s something that you have to constantly discuss with the manufacturer to make sure you’re getting what you want.”

To collect steel slugs when running nail-strip type metal panels, a portable rollformer trailer was customized with a drawer to catch the slugs by making a cutout in the deck and welding a frame underneath. Photo courtesy of Cidan Machinery.

Remember to Lubricate

Other maintenance tasks to consider include lubrication and managing oil. For portable rollformers with hydraulics, the hydraulic oil can be changed annually, or sooner, based on use, Bradley says. For machines with a small gas engine, operators follow their oil changes at proper intervals, as well.

One critical place to lubricate on post-cut machines is the shear, Bradley says. “We use a synthetic oil-based lubricant with a PTFE (polytetrafluoroethylene) in it, and that PTFE adheres to the shear blades and dies, and fills in any microscopic machining marks. And essentially what it does is helps reduce friction for the blades. The lubrication process helps prolong the life the blade.”

Additionally, Bradley says, “You want to look and make sure you’re lubricating the drive gears. All of our machines have chains in them, so you want to maintain proper chain tension and lubrication.”

For the chain on MRB’s rollformer, Walund says, “We use dry lube on the chain. You don’t want dirt collecting on the chain, so you don’t want to use WD-40 or anything like that. It’s more of a dry lube.”

Cover It Up

Another way to minimize maintenance issues is to cover portable rollformers when they’re not in use, and especially when traveling, McLauchlan says. It’s also well worth the cost to get a cover specifically made for a rollformer, and the time it takes to put it on and remove it, he says. “I saw S-hooks in a machine from bungee cords,” McLauchlan says. “The guy didn’t want to spend the money on the custom fit cover for the machine, but went and bought blue tarps, and bungee corded it on. And one of them fell off and it ended up inside the machine and ran through the tooling station to where they scarred a tool. And I saw that more than once.”