Solvent-based polyvinylidene fluoride (PVDF) coatings have been the hallmark in performance for metal roof and wall panels for over 50 years, and are the product of choice for architects specifying a premium exterior coating system for buildings. Now there is a new aqueous PVDF latex resin technology for field application of metal restoration coatings.

Designed to outlast conventional coating products

This office building restoration in Southern California was completed with metallic, water-based PVDF coating. (Photo courtesy of APV Engineered Coatings Inc.)

The primary features of the new product are its ability to offer an extremely high solar reflectance, which is retained longer than conventional spray coatings and its availability in a palette of colors used for restoration applications.

Whereas solvent-based PVDF coatings are relegated to factory application on metal due to the high cure temperatures, water-based PVDF coatings can be factory or field applied to a wide variety of substrates, such as metal, thermoplastic polyolefin (TPO), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), spray polyurethane foam (SPF), fiber cement and more, to enhance the performance or extend their useful lives.

PVDF homopolymer is a weatherable coating resin. Its durability is a result of the chemical composition of the resin relying on the carbon-fluorine molecular bond: one of the strongest bonds known to mankind.

A solvent-based PVDF paint finish displays superior color retention because the resin is transparent to ultraviolet (UV) solar radiation. Conventional resin-based exterior paint finishes are normally attacked by UV energy, heat and moisture. In these types of finishes, the UV energy is absorbed by the film and degrades the molecular structure which can attack the resin and the colored pigments resulting in fading, chalking and film erosion. This type of comparative superior weathering performance has been documented for over 50 years since the introduction of the premium exterior finish.

Hence, the strength of the solvent-based PVDF technology platform used for pre-painted metal roofing and wall systems has been well established and documented. And, coatings now made with water-based PVDF latex offer the same level of performance, including:

• Superior long-term color and gloss retention

• Superior resistance to chalking

• Outstanding resistance to dirt pick-up and stain

• Excellent resistance to algae and fungal growth

• Excellent resistance to abrasion

• Superior retention of high solar reflectance and thermal emittance

In addition to the above attributes, water-based PVDF coatings have excellent color stability and diversity in vibrant colors that make the product a main choice for architects and building owners in the roof and wall restoration market. An excellent application for water-based PVDF coatings is metal restoration, in particular, metal roofing and walls.

A building owner may prefer to recoat their structure for a number of reasons:

• Recoating is more cost effective than retrofitting

• Color change

• New corporate identity

Water-based PVDF coatings can be formulated with cool pigment technology which reflects infrared solar energy. In some areas, recoating your structure with a system based on a water-based PVDF coating can qualify the building owner for an energy rebate such as in Florida through Florida Power and Light. Manufactures offer a variety of non-white colors that qualify for such a rebate.

These low-VOC coatings provide outstanding water repellency, and retain color and gloss like no other conventional water-based coating making them ideal for field applications, including metal restoration, with cool roof and cool wall technology. The water-based PVDF topcoat is part of an overall system. Just like any paint restoration, surface preparation is important. All surfaces must be sound, clean, dry, and free of contamination.

The system usually requires a primer. This means that the applicator should follow the topcoat manufacturer’s recommendation for primer selection and coating application. Water-based PVDF coatings can be applied with a brush, roller or commercial spray systems.

Water-based PVDF coatings have a long-established reputation for being durable exterior paint systems. The new platform is truly cutting-edge technology that creates a new standard in the area of field-applied air-dry coatings for roof and wall restoration.

Field application of water-based PVDF coatings is practical and economical when compared to coil coating or pre-painting of metal roofing. The features of the coating make it a sustainable product as part of a green building practice. Water-based PVDF coatings are available in North America and worldwide through licensed coating formulating companies.

Vince Casmirri is regional marketing manager at Arkema Inc., King of Prussia, Pa. To learn more, visit www.arkema-americas.com.

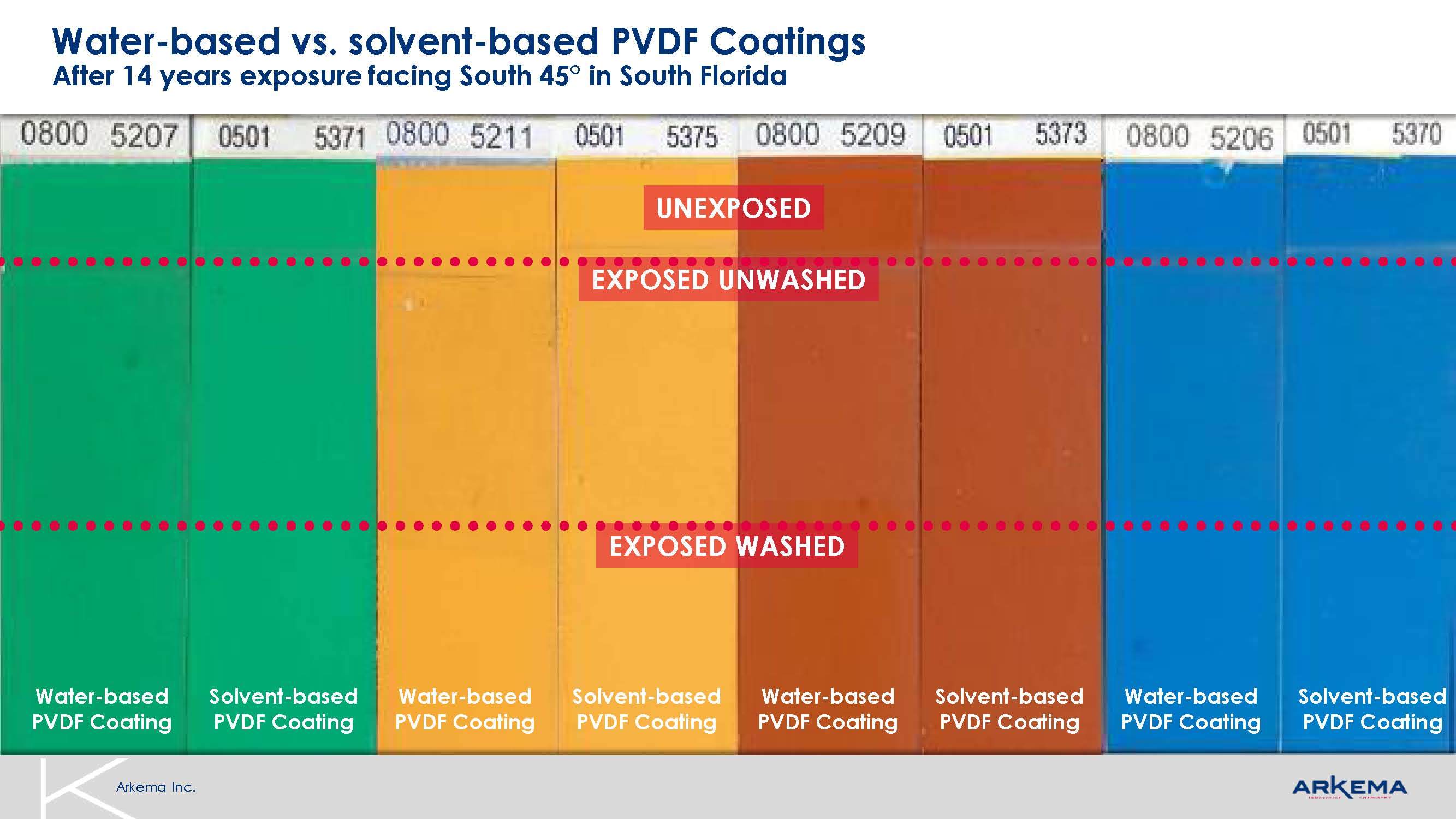

The testing of water-based PVDF coatings has been ongoing in South Florida for many years. This figure shows the performance of mass tones in a variety of colors after 14 years in Florida. Comparing the original colors to the exposed surfaces shows excellent performance similar to that seen on the panels featuring the solvent-based PVDF paints.