Pre-engineered metal building helps new church worship, connect, serve

On June 2, 2013, members of the Christ United Methodist congregation dug shovels into soil to begin the foundation for a new church in Fairfax Station, Va. They sang Christian songs about their hope for the new church, with lyrics like, “Greater things are yet to come, greater things are still to be done in this city,” and families joined together to pray for the construction crew. Many filled jars with dirt as a reminder to pray for the safety of those working on the site and for the people that would one day step foot into the new building.

On June 2, 2013, members of the Christ United Methodist congregation dug shovels into soil to begin the foundation for a new church in Fairfax Station, Va. They sang Christian songs about their hope for the new church, with lyrics like, “Greater things are yet to come, greater things are still to be done in this city,” and families joined together to pray for the construction crew. Many filled jars with dirt as a reminder to pray for the safety of those working on the site and for the people that would one day step foot into the new building.

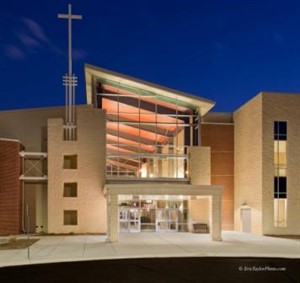

Their new, 50,000-square-foot project named Christ Church, completed in August 2015, was converted from an originally planned conventional steel building with a membrane roof to a pre-engineered metal building (PEMB). As outlined in the original vision of its founders, it now has enough land to be a regional church with attractive, efficient facilities for worship, Christian education, a Christian school, youth center, counseling center and elder care.

Moving from a campus that they occupied for 20 years located deep within a housing development that could not be seen from any main road, church founders wanted a location that would be visible and accessible. And, “[The old church] was limited to 350 people in its worship center,” says Debra Merrill, executive director at Christ Church. “From the very beginning we knew that we would need to find a location that was large enough to hold 600 to 1,000 people in worship per service. One of the major functional requirements was that each space in the building would be able to serve multiple functions, so flexibility was key. We also wanted to embrace the natural beauty and light of the surrounding woods, therefore the use of natural materials, windows and light access were important design elements.”

Cost-effective Conversion

Though the new church was designed in 2006, progress was stalled in 2007 along with (and because of) the United States economy. The economy’s downturn, just as construction was to start, required a complete redesign of the structural approach to reduce costs. Merrill says the terms of the church’s loan changed, requiring more cash up front rather than pledges. Church leadership was forced to ask: How could we do it in a more costeffective way?

To work around this obstacle, the church construction team came up with a solution that incorporated two PEMBs, supplied by Eufaula, Ala.-based American Buildings Co., joined in the middle with a covered central walkway. This not only accomplished an almost identical vision to the original plan but also saved millions of dollars in construction costs. Manassas, Va.-based Whitener & Jackson Inc. functioned as a traditional general contractor by managing the construction process, but also as the design-build contractor for its PEMB components.

To work around this obstacle, the church construction team came up with a solution that incorporated two PEMBs, supplied by Eufaula, Ala.-based American Buildings Co., joined in the middle with a covered central walkway. This not only accomplished an almost identical vision to the original plan but also saved millions of dollars in construction costs. Manassas, Va.-based Whitener & Jackson Inc. functioned as a traditional general contractor by managing the construction process, but also as the design-build contractor for its PEMB components.

The company coordinated the design of the primary structure, as well as the secondary structural elements such as light-gauge framing and wind bracing. It also facilitated the change in the roof system from membrane roofing to standing seam metal roofing, including flashings, roof penetrations and a roof screen for the rooftop mechanical equipment to replace the masonry parapets.

The church owner initially selected another contractor for pre-construction services and had been working with them for several years. “When at the end of the pricing and value-engineering process, the project was still significantly over budget, they turned to us for help,” says Curt Nette, senior project manager at Whitener & Jackson. “We came up with the idea of a significant structural redesign to get them back within budget, without compromising the size or appearance of the building they had grown to love.”

From Conventional Steel to PEMB

Fitting a new PEMB structure into an existing building shell was particularly challenging for the construction team. Manny Kim, building systems engineer at Whitener & Jackson, served as the team coordinator for the design change effort. American Buildings utilized Building Information Modeling (BIM) to overlay its existing shell on the new structure and allow Whitener

& Jackson to identify structural and bracing element conflicts.

For instance, a number of column and beam flange braces initially ended up below the ceiling or on the room side of a column enclosure and had to be relocated. “The light-gauge framing supporting the exterior masonry veneer required a series of spandrel beams to reduce the vertical span and transfer reasonable loads to the PEMB structure,” Kim says. “The late addition of a two-hour fire separation wall to reduce the fire area of the building required a unique design by McLean, Va.-based structural engineer Ehlert-Bryan and HH Architects, Dallas, of a breakaway structure that would allow the firewall to remain intact in the event the structure on either side collapsed.”

For instance, a number of column and beam flange braces initially ended up below the ceiling or on the room side of a column enclosure and had to be relocated. “The light-gauge framing supporting the exterior masonry veneer required a series of spandrel beams to reduce the vertical span and transfer reasonable loads to the PEMB structure,” Kim says. “The late addition of a two-hour fire separation wall to reduce the fire area of the building required a unique design by McLean, Va.-based structural engineer Ehlert-Bryan and HH Architects, Dallas, of a breakaway structure that would allow the firewall to remain intact in the event the structure on either side collapsed.”

While the driving factor in the change was budget, as the redesign progressed, intangible benefits became apparent. For instance, the main gathering area was originally designed to have an exposed structure with false brace rods and oversized roof beams. “The PEMB structure fulfilled that visual requirement while actually providing the structure and bracing required to support the building,” Nette says. “A handful of ‘false’ brace rods were introduced for uniformity, but the bulk of the structure is functional.”

Church Challenges

Pricing and PEMB positioning weren’t the church’s only challenges. Lime, 274 tons of it, had to be blended into the soil to support the structure’s foundation. Unstable dirt had to be dug, hauled, stored and conditioned to create a suitable foundation for the building and the parking areas. One of the challenges faced by Thurmont, Md.-based MTD Erectors was the architect’s desire to conceal the church’s many HVAC units, something that resulted in changing the roof elevation design three times. “Trying to conceal them, so no one could see them, created five different elevations on the PEMB,” says Mark Overcash, president, MTD Erectors. “We lowered them down into an equipment area and in one part of the building we installed a 10-foot screen. It was an exercise in itself just pricing it.”

Evaluating, selecting and positioning different wall types were also a challenge for Overcash. “At one point we had panel-ribbed walls with insulation,” he says. “Then we went to insulated wall panels and priced that out and then we went back to the panel-ribbed walls. Every time we made a change, it affected pricing.”

Evaluating, selecting and positioning different wall types were also a challenge for Overcash. “At one point we had panel-ribbed walls with insulation,” he says. “Then we went to insulated wall panels and priced that out and then we went back to the panel-ribbed walls. Every time we made a change, it affected pricing.”

The church did not use a normal trim package due to the architect’s and the owner’s desire to keep the building’s original design intent intact. “Because we were intersecting with different wall types, we sent out the trim and received some material bent that would work for the transition from stucco to panels, and from blocks to panels,” Overcash says. “The trims that wrapped around the stucco walls were made special because you didn’t want to see any fasteners. We used a lot of cleated metals to not see the fasteners or anything in the trim. We wanted a nice, clean job.”

Converting from the originally designed membrane roof system challenged the church’s architects to rethink its sloping drainage elements. “We had some offsets to deal with in regards to valleys and different guttering procedures,” says Bruce Woody, AIA, president and CEO of HH Architects. “It worked well because the metal building components allowed for a good low slope that really didn’t affect the architecture that much.”

Skin and Insulation

The church’s original exterior skin was designed with brick, split-faced block and EIFS, and light-gauge metal framing. Those elements were maintained on the permanent and visible façades of the building, while girts and metal siding were used at the rear of the building where a future addition fitting in with the original master plan will be built. “Not only did this reduce the initial cost, but it also will allow for easy connection of the future addition by simply removing panels from inside the completed shell of the addition,” Woody says.

The church has an Optiliner multi-layer insulation and facing system from Bay Insulation Systems, Green Bay, Wis., to provide insulation between the roof purlins as well as the more traditional over-thepurlin installation. This provides a higher R-value as well as noise reduction from sources such as heavy rains and thermal expansion/contraction of the metal roof. The lower level is installed on a series of straps attached to the bottom of the purlins, while the second layer is placed over the purlins as the roof panels are installed.

“The facing was ordered in black to minimize contrast in the ceiling when the exposed structure was painted black,” Kim says. “This system requires Sammy X-Press fasteners [from ITW Buildex, Itasca, Ill.] to attach components to the purlins as the bottom flange is not accessible for securing hangers with a traditional nut and washer.”

“The facing was ordered in black to minimize contrast in the ceiling when the exposed structure was painted black,” Kim says. “This system requires Sammy X-Press fasteners [from ITW Buildex, Itasca, Ill.] to attach components to the purlins as the bottom flange is not accessible for securing hangers with a traditional nut and washer.”

Overcash says he sees many buildings using this type of insulation to attain higher R-value ratings, but insists that it must be installed correctly. “We didn’t want to get it wrinkled,” he says. “We took a lot of time to stretch it to get to look nice. When you look up, it looks like a finished ceiling. Black is not the norm, but it looks nice.”

Overall, Merrill says everyone is thrilled and very proud of their new church home. “It is stunning, modern but not cold; open but intimate and friendly at the same time,” she says. “From the moment we opened for worship, people instantly settled in as if they had been here forever. People stop in from the road on a weekly basis to just see the building as the newest local attraction.”

———————————————————————————————-

Sidebar: Two Architects and a Church

Metal Construction News asked Christ Church architects Gary Kirchoff, AIA, LEED AP, CDT, principal, and Bruce Woody, AIA, president and CEO, of HH Architects, Dallas, to describe in their own words their involvement with the project.

We launched into the initial design change with the owner and all the consultants redesigning the building from the inside out with metal building components and metal building skin with many of the original design components still intact.

We use Revit software exclusively for our projects for modeling and clash detection. The contractor and its metal building manufacturer shared their 3-D model with us. We were able to insert their 3-D model into our model and we began to replace the conventional structural components with the pre-engineered metal building (PEMB) structural components. We used their 3-D model as part of our document so every time we received an update from them we inputted their model into our Revit model. We then carefully went through it looking for clash detections or problems with building materials mechanical systems.

Sidebar: Christ Church, Fairfax Station, Va.

General contractor: Whitener & Jackson Inc., Manassas, Va.

Architect: HH Architects, Dallas

Metal building erector: MTD Erectors, Thurmont, Md.

Structural engineer: Ehlert-Bryan Inc., McLean, Va.

Fasteners: ITW Buildex, Itasca, Ill., www.itwbuildex.com

Insulation and facing system: Bay Insulation Systems, Green Bay, Wis.,www.bayindustries.com

Metal building system, mezzanine steel, standing seam roof: American Building Co., Eufaula, Ala., www.americanbuildings.com

Photos: Eric Taylor, Taylor Design & Photography Inc.