The Minnesota National Guard Division Headquarters complex serves as the new home for the 34th Infantry Division known as the Red Bulls.

A National Guard facility is reimagined for a new era

Photos: Corey Gaffer

Its new 14,735-square-foot General John W. Vessey Readiness Center in Arden Hills, Minn., has grown significantly in personnel, equipment and technology, and this new facility provides necessary administrative, training, secure work and storage areas. The new headquarters provides training and readiness, and embodies the National Guard’s commitment to durability, longevity and efficiency.

It has been named the Grand Design Award winner (built) in the Society of American Military Engineers’ biannual Design Awards program. Representing the highest honor for a facility, infrastructure, landscape or planning project designed for a SAME partner agency (DoD, VA, DHS, Public Health Service, or GSA) worldwide, the award recognizes the project as one of the best works of federal architecture built this decade.

LEO A DALY, Omaha, Neb., was the design architect, interior designer, civil, structural and mechanical engineer for the project. Built by Stahl Construction, Minneapolis, the facility was delivered design-bid-build, like all National Guard projects. “It was really good working with Stahl Construction from start to finish,” says Nik Weller, associate, senior designer at LEO A DALY, located in Minneapolis. “We kept each other accountable and made an effort to always be available to help each other overcome any issues that arose and to ensure the National Guard would have a facility they could be proud of down to the smallest detail.”

Metal Perforation and Cladding

Almost all of the metal architectural features inside and outside the building have a specific pattern of perforation. “They are three-quarter inch round perforations spaced vertically an inch and a half, horizontally an inch and three quarters, and staggered,” Weller says. “The sunshades and balcony railing [both from Astro Engineering and Manufacturing, Hanover, Minn.] have the same perforated metal pattern that shows up in the display case backing, the grand stair and the exterior stormwater downspouts. Walking though the facility, you recognize the pattern and it becomes a signature of the design.”

Each of these pieces was manufactured by a different manufacturer, and it was a challenge to ensure that the pattern matched among all the different pieces. “For manufacturers, the most efficient thing to do is use their stock perforated metal,” Weller says. “It takes more time and costs more in CNC time to manufacture a specific pattern like ours where the horizontal dimension is different from the vertical, and they’re staggered. They had to design that pattern, replicate it and overlay it over the rigging of their scope. It takes more time to set up.”

The other major metal component is the corrugated cladding—black, corrugate 20-gauge, galvanized, profile BR5-36 metal panels from CENTRIA, Moon Township, Pa.—on the exterior. “We chose it because it is very cost-effective, and because it complemented the other surface types used throughout the exterior,” Weller says. “The vertical lines of the corrugated metal panel create the perfect blend between the flatness of the resin panels and the very busy digital camouflage pattern used in the precast concrete.”

Shadow-like into the Environment

The building strikes a low linear presence, disguising its expansive scale. Nestled among the rolling hills, wetlands and mature oak trees of a federal cantonment area, the project makes landscape a central focus of the design. The black building blends shadow-like into the environment while working to mitigate its impact on the surrounding ecosystem.

From a previously contaminated state, the site has been restored to natural harmony, with building systems, waterways and old-growth forest integrated as a sustainable whole. Native plantings surround the facility, mitigating the need for irrigation and excessive maintenance with fuel-powered equipment.

Black textured concrete façades are subdivided by the soaring slivers of vertical glass. The design allows for striking reflections of foliage and sky, creating a mirage of transparency, like a passive camouflage. The linear parti was oriented to leverage the passive benefits of southern exposure, protecting glazing from the predominant winds and cold from the northwest. Entries and walkways are warmed by the sun, storing thermal energy and advancing the rate of ice melt during the winter months.

Three Functional Masses

The facility is organized around a central hub and divided into three functional masses to accommodate the operational specifics of National Guard training. This led us to a design that is organized into three functional masses.

“The central hub is a high-volume, two-story node that houses common use spaces and allows the Guard to host dignitaries,” Weller says. “The west wing is a single-story, concrete-enclosed mass that provides storage and enables logistics training. The east wing is a secure, class-A office space that is needed by the modern National Guard to conduct advanced cyber activities. Understanding the National Guard’s mission allowed us to organize and outfit each space to the right size and level of expense and amenity to maximize efficiency without sacrificing performance or quality of life.”

Functioning as a modern workplace, the east administrative wing appears a single story from the front of the building. A lower level is revealed on the north side as the site elevation drops dramatically toward the marshland. The layout of the “neighborhoods” in the office wing allows for the mechanical systems and spaces to be tuned to the changing daily needs, saving energy and enhancing the experience for its users. Anchored by a high-volume, two-story, (above-grade) central common area, occupants maintain a visual connection between floors throughout a large atrium.

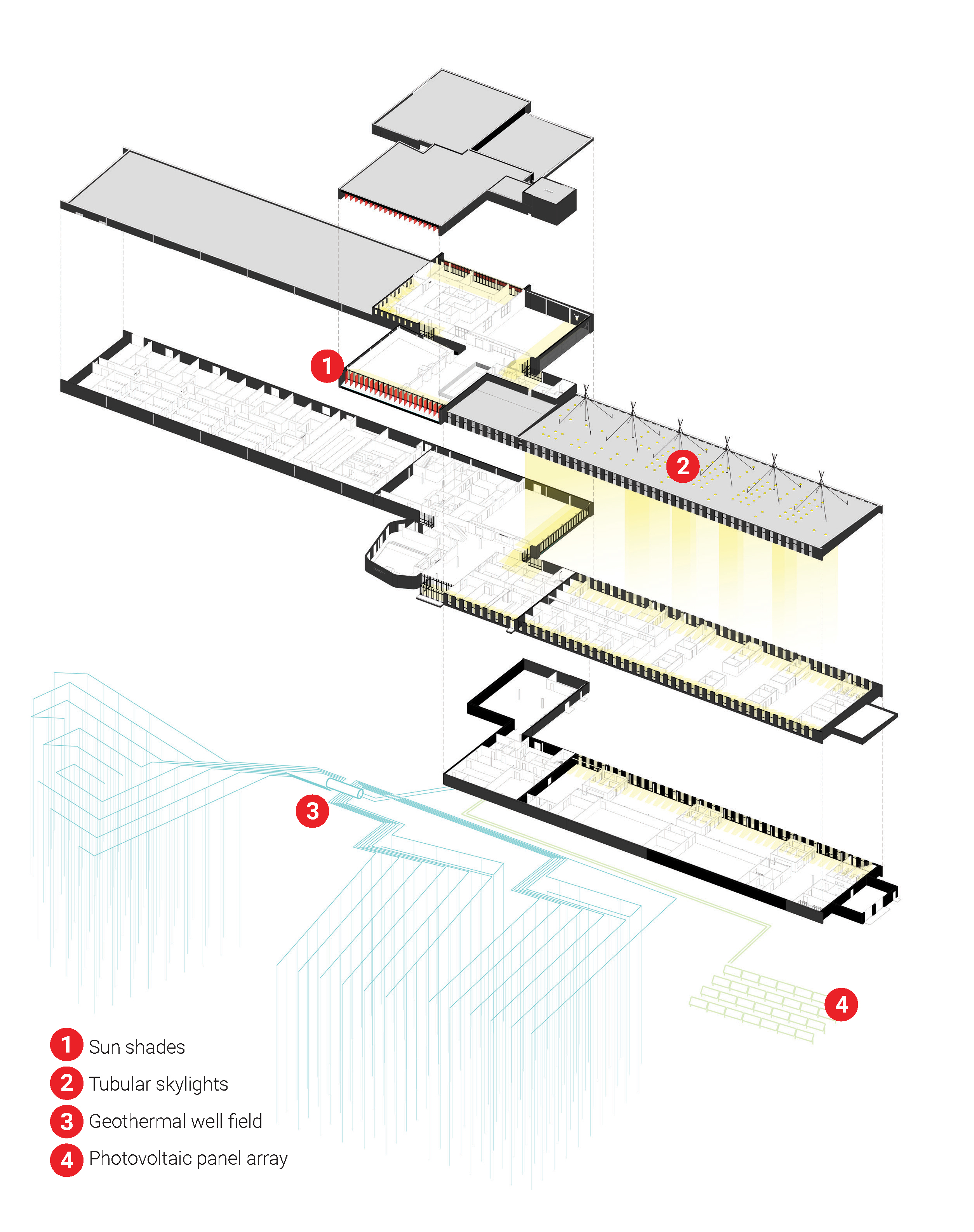

Diagram courtesy of LEO A DALY

Adaptability

During construction the National Guard determined that an additional unit would be housed in this facility and the need for adaptability was immediately tested. The structural strategies and functional layout embedded within the design were ready for this type of adaptation and accommodated without negatively impacting its design.

The linear wings or the facility are expansive and column-free. The underside of the roof structure was left exposed, resulting in the visual effect of a striking pattern of smooth white channels in contrast to the dark, moody exterior. Functional organization strictly followed a modular layout, aligning with the beam and fenestration locations.

LEED Gold-Certified Center

The facility was awarded LEED Gold certification by the U.S. Green Building Council. To maximize sustainability, the design includes geothermal systems, photovoltaic arrays and EnergyStar equipment. Solar panels harness energy from the sun to offset the facility’s electrical draw from the grid. Energy Star is a partnership program of the U.S. Environmental Protection Agency (EPA) that helps the National Guard save energy and protect the environment through superior energy efficiency. It helps them measure, track and reduce their energy use, water consumption and greenhouse gas (GHG) emissions.

“The geothermal well system allows us to harness the temperature of the earth itself to do work without consuming energy,” Weller says. “A liquid is pumped through a series of geothermal wells (buried tubes) all year round, and depending on the season, it goes out cool and comes back warmer, or goes out warm and comes back cooler. This temperature change is then harnessed through the use of heat pumps and used to either pull warmth out of the interior air in the summer or add warmth to the interior air in the winter.”

LED lights are a more efficient alternative to incandescent lights. “In addition, the building uses 115 solar light tubes to introduce natural light deep into the office space, avoiding the use of artificial light,” Weller says. “Ample windows add to the daylight, and sunshades limit the amount of heat gained during the summer from solar radiation. All of this coalesces to greatly reduce the amount of electricity used to operate the building.”