According to the National Renewable Energy Laboratory, more energy from the sun falls on the earth in one hour than is used by everyone in the world in one year. With energy demands continually increasing, along with the need for new and clean energy sources, the world’s fastest-growing energy technology is solar.

According to the National Renewable Energy Laboratory, more energy from the sun falls on the earth in one hour than is used by everyone in the world in one year. With energy demands continually increasing, along with the need for new and clean energy sources, the world’s fastest-growing energy technology is solar.

“The sun is our most reliable source of clean renewable energy,” says Jerry Heininger, coordinator of environmental products at Englert Inc., Perth Amboy, N.J. “Despite some bad press from the demise of several solar companies and the influx of foreign solar components, the future of solar energy in this country is still quite sunny. We have an ever-growing demand for additional energy that will need to be satisfied. Over the next 30 to 40 years it is expected that solar will provide 25 percent of our energy needs.”

Metal roofing systems are the perfect photovoltaic (PV) host, a fit that provides many benefits for the building and its owner. What follows are some next-generation PV technologies on the solar power horizon.

Building-integrated photovoltaics

Building-integrated photovoltaics (BIPV) are integrated into the building envelope. They replace conventional building materials in part of the building envelope, such as the roof, skylights or façades. They are increasingly being incorporated into the construction of new buildings as a principal or ancillary source of electrical power, and existing buildings can be retrofitted with similar technology. BIPV’s advantage over more common non-integrated systems is that the initial cost can be offset by reducing the amount spent on building materials and labor that would normally be used to construct the part of the building that the BIPV modules replace.

Conventional solar panels are typically mounted at a fixed-tilt angle, representing a trade-off between summer and winter production. Adjacent rows of tilted panels must be spaced to avoid shading. This spacing reduces the amount of power on the roof. Inadequate spacing can result in significant power losses. Flexible BIPV systems enable simpler, more versatile and higher power density solutions for limited areas rooftop installations. This results in higher net energy production per rooftop.

Industry analyst firm NanoMarkets recently published its latest BIPV projections in a report titled, “Building-Integrated Photovoltaics Markets: DuPont’s Kapton colorless polyimide film, a transparent PV technology, is a new material currently in development for use as a flexible, fully monolithically integrated flexible solar module based on cadmium telluride. (Photo courtesy of DuPont) Advanced photovoltaic systems will enable new building designs and configurations. (Photo courtesy of Agustin Otegui) 2012.” NanoMarkets estimates that the entire BIPV market already generates around $2.1 billion today and that this figure will grow to $7.5 billion by 2015. The report claims much of this growth will come at the expense of conventional solar panels as BIPV’s economics and aesthetics make their impact on end users. NanoMarkets also expects new builds to contribute 63 percent of all BIPV revenues in 2015.

Indoor light energy

Wouldn’t it be nice (and much more efficient) if a PV system could produce energy from indoor lowlight sources in addition to the sun? SolarPrint Ltd., a company in Dublin, Ireland, thinks it can. It claims it has found a way to convert any light source into energy, similar to the way a plant converts light to energy using photosynthesis. The company develops Dye-Sensitised Solar Cells

(DSSC), a thirdgeneration printable solar cell technology to integrate with wireless sensors for energy-harvesting purposes in buildings. DSSCs are electrochemical devices comprised of a light-absorbing molecule anchored onto semiconducting titanium dioxide nanoparticulates. DSSCs consist of nontoxic and abundant materials.

DSSC-based wireless energy management systems provide significant cost savings by eliminating wired networks. The indoor light spectrum is very different from the outdoor spectrum. DSSC performs in low and diffuse light because it has a spectral response that completely overlaps and

matches with visible, ambient indoor light. This is its key to producing efficient power output in the indoor-operating environment and is DSSC’s advantage over other types of photovoltaics. Cambridge, Mass.-based IDTechEx is predicting that the DSSC market will slowly grow to $290 million by 2023.

Hybrid technology does more

Traditional solar PV systems convert approximately 15 percent of the sun’s energy into electricity and waste the remaining energy as heat. Solar efficiency would increase significantly if this surplus heat could be optimized. Naked Energy, Guildford, England, is trying to do this with a tubular hybrid solar panel that can do twice the work of a traditional flat PV panel. The product, called Virtu, can generate electricity and hot water simultaneously.

It draws heat away from the solar panel for space heating, hot water, desalination and cooling, and the photovoltaic is maintained at an optimum operating temperature. This results in significantly higher electrical output than standard PV panels. Both energy outputs are optimized replacing the need for two separate conventional panels (PV and thermal), reducing installation time and cost while maximizing useable installation area. Virtu’s vacuum tubes have low thermal losses, and will produce abundant hot water and heat regardless of being installed in hot or cold climates. The annual yield depends on the application, local climatic conditions and panel quantity installed.

With more than 30 customer projects, Mountain View, Calif.-based Cogenra Solar is the most experienced developer of solar hybrid electric and hot water solutions in North America. Cogenra calls its technology Solar Cogeneration because it can create both electricity and hot water from a combined solar photovoltaic and thermal module. With it, 75 percent of the sun’s delivered energy is converted. To attain this, Cogenra integrates silicon PV cells, concentrating planar optics with singleaxis tracking and an innovative thermal transfer system in a low-cost and scalable design.

Hybrid solar technology excels in high-energy consumption buildings, like hotels, retirement homes, factories and hospitals or wherever large amounts of electricity, hot water, space heating or chilling and utility scale installations for desalination and power generation.

Transparent efforts

A complaint about solar panels is that they are an “eyesore.” A new solar film, created at UCLA is trying to change that. This new type of photoactive plastic solar cell is nearly 70 percent transparent to the naked eye. The polymer solar cells (PSC) convert infrared light, instead of visible light, into electricity. It incorporates silver nanowires approximately 0.1 microns thick, about one-thousandth the width of a human hair, and titanium dioxide nanoparticles as an electrode. Because these PSC thin films are transparent, buildings could potentially use their own windows as solar panels and harvest their own power with them.

“These results open the potential for visibly transparent polymer solar cells as add-on components of smart windows, building-integrated photovoltaics and other applications,” says study leader Yang Yang, a UCLA professor of materials science and engineering, and director of the Nano Renewable Energy Center at California NanoSystems Institute (CNSI). Yang says there has been intense worldwide interest in polymer solar cells. “Our new PSCs are lightweight and flexible,” he says. “More importantly, they can be produced in high volume at low cost.”

In addition to UCLA’s research, scientists at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory and Los Alamos National Laboratory have also fabricated transparent thin films capable of absorbing light and generating electric charge over a relatively large area. The material consists of a semiconducting polymer doped with carbon-rich fullerenes to absorb light, and efficiently generate charge and charge separation.

The material remains largely transparent because the polymer chains pack densely only at the edges of the hexagons, while remaining loosely packed and spread very thin across the centers. The densely packed edges strongly absorb light and may also facilitate conducting electricity, while the centers do not absorb much light and are relatively transparent. Combining these traits and achieving large-scale patterning could also enable energy-generating solar windows and transparent solar panels.

Engineering plastics will be a vital part in PV’s future. “One main reason for the increasing interest in plastic solutions is their freedom in design and form,” says Andre Schaefer, application development engineering plastics Europe, BASF SE, Ludwigshafen, Germany. “The parts can be mass-produced in high volumes via injection molding. This process integrates different functions easily into one part and ready-to-use parts can be manufactured economically in only one processing step. Time-consuming finishing is not required anymore. Through the option to construct complex geometrical parts, additional elements like snap-fits or hooks can be integrated. This reduces mounting time on the roof or on the field.”

Concentrated is coming

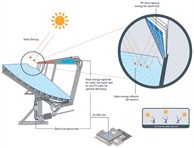

Concentrated photovoltaic (CPV) technology uses optics, such as lenses or curved mirrors, to concentrate a large amount of sunlight onto a small area of PV cells to generate electricity. Compared to non-concentrated photovoltaics,

CPV systems can save money on solar cell cost, since a smaller area of PV material is required. Because a smaller PV area is required, CPVs can use more expensive high-efficiency tandem solar cells. To get the sunlight focused on the small PV area, CPV systems require spending extra money on concentrating optics

(lenses or mirrors), solar trackers and cooling systems.

CPV systems operate most efficiently in concentrated sunlight, as long as the solar cell is kept cool through the use of heat sinks. Diffuse light, which occurs in cloudy and overcast conditions, cannot be concentrated. To reach their maximum efficiency, CPV systems must be located in areas that receive plentiful direct sunlight.

Because of these extra costs, CPV is far less common today than non-concentrated PV. Still a young application, ongoing research and development is trying to improve CPV technology and lower costs to foster it usage. As long as there is sunlight, CPV and many other solar-harvesting devices will ensure photovoltaics will be an energetic technology for the future.