Almost every commercial construction project requires crews to attach something to concrete, and often it is a metal screen or other metal building product. But there are few standardized guidelines for the proper way to do it, and reports from the field reveal that installation processes vary considerably not only from job to job but from crew member to crew member.

Installation steps you need to know before you drill and anchor the hole

The Simpson Strong-Tie Strong-Bolt 2 wedge anchor is torque activated, installs through the fixture, and expands and fastens in one operation. (Image courtesy of Simpson Strong-Tie)

When installed correctly, though, anchors bonded or mechanically attached inside drilled holes can be as strong as or stronger than cast-in-place systems. However, if the right anchor is not installed correctly, a complete assembly failure can occur.

The Whole Hole

Anchoring into a concrete wall for this connection requires drilling a precise pilot hole with very specific size and depth requirements. These requirements determine much of the anchor’s holding success. However, “there is no standard, like an ASTM or ANSI standard, that is generic and specifically states how the drill hole is to be created,” says Donald F. Meinheit, affiliated consultant for Wiss, Janney, Elstner, Associates Inc., Chicago. “The directions for drilling the hole, that is, the diameter of the drill bit and depth of the hole, are listed for each anchor in the manufacturer’s printed installation instructions

(MPII).”

While hole diameter size varies, most are close to 1/4-inch. If a threaded anchor is used, the pilot hole should be smaller than the diameter of the concrete anchor. The hole must be larger if a wedge, sleeve, epoxy or a “spike” type anchor is used. Most holes are 1/4- to 1/2-inch deeper than the anchor itself. Refer to the manufacturer’s recommended instructions. Most anchor manufacturers base hole size and other information on independent lab results that determine an anchor’s rated capacity.

There are many different types and shapes of concrete fasteners and each anchor’s installation is unique. Be sure appropriate installation techniques and proper tooling are used to ensure correct pilot holes and holding values. “The anchor’s embedment depth should be based on the loading conditions the anchor needs to withstand,” says Chris La Vine, senior engineer at Simpson Strong-Tie, Pleasanton, Calif.

The Drill and the Drill Bit

To drill holes for concrete anchors, there are three generally accepted methods: rotary-hammer drilling, rock drilling (rotation, percussion and air pressure) and core drilling. According to Meinheit, there is no one method that is most appropriate for each type of anchor. Mechanical expansion anchors and concrete screws generally need an accurate diameter, whereas, adhesive anchors need a good roughened hole to achieve a bond between the adhesive and the concrete substrate.

The Ankr-TITE CCAT wedge anchor has a unique safety shoulder that supports the climp when the anchor is under strain and a dog point that prevents damage during installation. (Photo courtesy of Wej-It Fastening Systems)

Hammer drills are small tools designed for drilling holes up to about 1/2-inch in diameter. Rotary hammers range in size, some are capable of drilling up to 1 1/2-inch diameter holes. “These tools drill and hammer at the same time,” says Jeff Dunagan, senior engineer, at Simpson Strong-Tie. “To create a hole in concrete, a chiseling action is needed. To make the holes round, rotation of the chisel is needed. These tools provide these two actions simultaneously.”

Most drill bits use a SDS chuck. Standard drill bit sizes are specified in the American National Standards Institute (ANSI) International Standard B19.11M. “Use a carbide tip drill bit specifically designed for concrete and masonry that is the correct diameter based on the type of anchor used,” says Joe Stager, vice president of product development and marketing, Triangle Fastener Corp., Pittsburgh.

Carbide drill bits are typically made of tungsten carbide that is nickel based with a carbon coating. This type of drill bit has many applications, such as drilling into stone, metal and removing screws that will not come out of metal. Standard drill bits are not that strong and are made of a lesser quality material that can bend or break when drilling into hard materials like concrete.

A carbide chisel built into the bit’s end can chisel the hole to the desired depth. The flutes on the bit’s shaft remove the drilling dust. These bits have different shank configurations that mate with different types of hammer drills and rotary hammers. Always use a drill bit that complies with ANSI B212.15-1994, American National Standard for Cutting Tools-Carbide Tipped Masonry Drills and Blanks for Carbide-Tipped Masonry Drills, American National Standards Institute, which is the standard for carbide blanks used on single-point tools.

Anchor Installation Steps

The procedure for drilling into concrete is virtually the same for almost any style anchor. The following installation steps are provided by David Garfield, owner of Wej-It Fastening Systems, a division of Mechanical Plastics Corp., Norwalk, Conn.:

• Buy a good quality drill with variable speeds, hammering function, depth setting and power. Using a cheap drill with less power will potentially make holes that aren’t deep enough or off the mark.

• Read the user’s manual for the drill, and get to know what all of the knobs and controls are for.

• Set the depth-some drills will have a depth setting or depth control bar. If the drill does not have depth control, measure and mark the required depth with tape.

• Hold the drill properly with one hand like a gun and with your index finger on the trigger. If the drill has a handle for your other hand to hold, use it. Otherwise put your other hand at the back of the drill.

• Mark the point on the concrete wall, floor or ceiling where you want to drill. Place your drill on the mark and apply enough pressure to hold it in place-don’t press it too hard. Drill using a low speed or in short bursts. Make a shallow hole that will guide the drill so the hole is made exactly on the mark.

• Using a high speed and the hammer function (if the drill has it), drill into the shallow hole made in the previous step. Use some force against the wall, especially if the drill is not too powerful. Stop once you reach the desired depth.

• Sometimes drilling a hole won’t go as expected. You might hit something behind your substrate or a hard piece of concrete. If this happens, insert a masonry nail into the hole and hammer to get rid of the blockage. Insert the drill back and continue drilling.

• Once the hole is drilled properly, insert a fastener/anchor and follow the instructions for proper installation.

Remember to use earplugs and safety goggles during drilling and to always follow the manufacturers’ safety precautions when using power tools.

Rotary hammers range in size, and can drill and hammer at the same time. (Photo courtesy of Metabo Corp.)

Concrete Conditions

Different concrete types have an impact on anchor holding power. “Anchors in lower strengths of concrete perform differently than the same anchors in very high-strength concrete,” Meinheit says. “If the concrete is very high strength there may be difficulty in getting some of the anchors to function properly.”

Some concrete may be too brittle to withstand the installation techniques required for a specific anchor. The concrete’s rate of strength gain is affected by use of supplementary cementitious materials (SCMs), like fly ash and slag cement. The more Portland cement that is replaced with SCMs, the slower the strength gain.

Different types of concrete require different anchors that can be used. “Wedge anchors are used for concrete aggregate that is harder than 2,000 psi,” says Garfield. “When anchoring into less dense concrete, hollow block or brick, we recommend using sleeve anchors and other anchoring products. Every application and environment will determine which anchor or drill bit will be the correct product to use.”

Regardless of the type of concrete used, removing the concrete spoil or dust is important after drilling. “For a mechanical expansion anchor, the concrete spoil is usually removed by blowing the hole with compressed air,” says Neal S. Anderson, PE, SE, vice president of engineering at the Concrete Reinforcing Steel Institute, Schaumburg, Ill. “For an adhesive anchor, the hole cleanout procedure is quite important and is prescribed through the MPII.”

Metal Factors

The metal’s grade, thickness, size and weight being attached impact anchor installation and selection. The anchor’s holding strength must exceed the load value of the tensile load being applied by the metal being attached or pullout will occur.

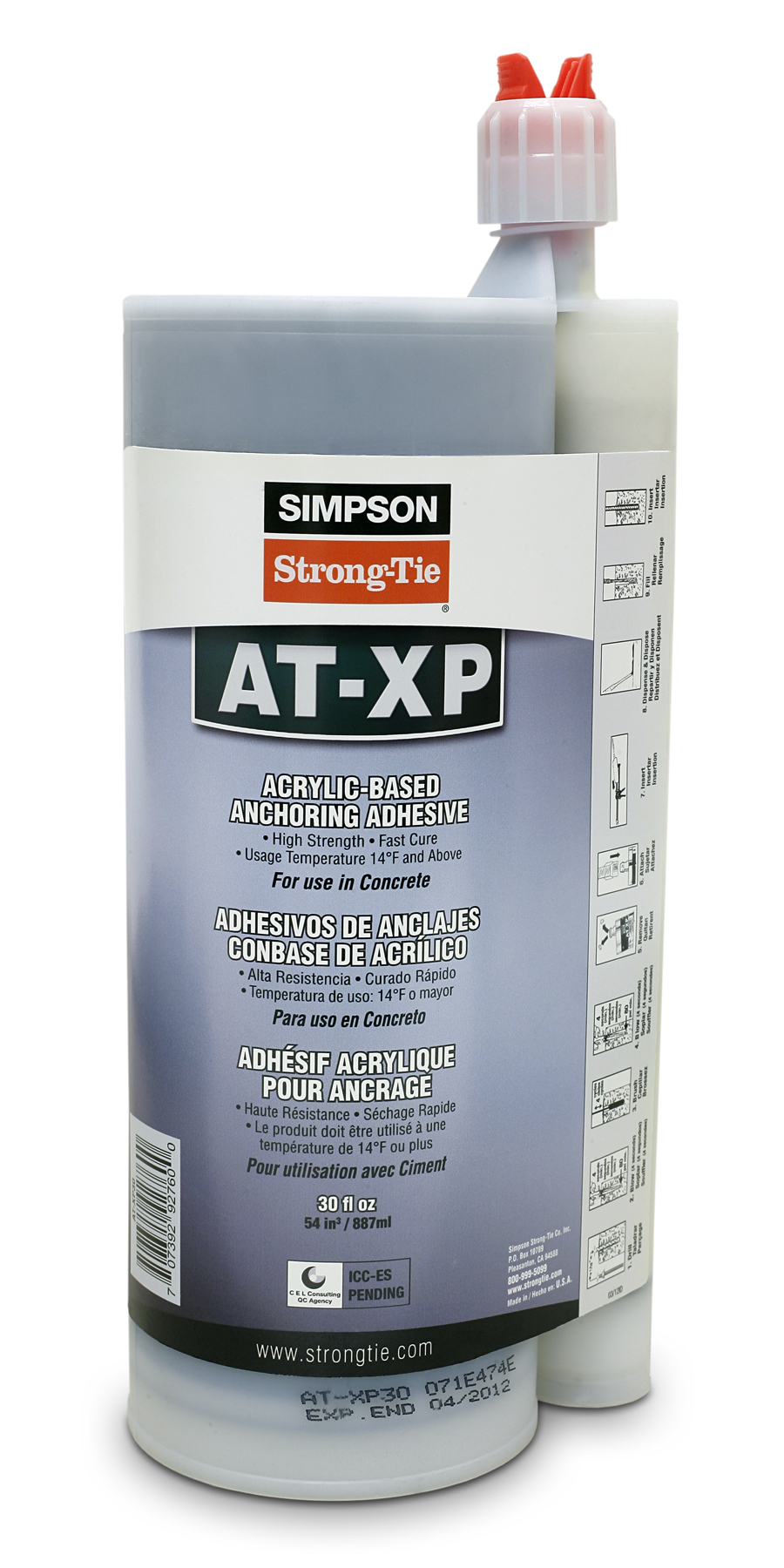

Simpson Strong-Tie AT-XP anchoring adhesive is easy to install and can handle adverse service-life conditions. (Photo courtesy of Simpson Strong-Tie)

The larger the loads, the larger and deeper the anchors or the more anchors you need. “If we are talking about heavy-industrial loads, the postinstalled anchor is not the correct choice,” says Meinheit. “If embedment is into a member that is heavily reinforced with reinforcing bars, drilling the holes is very difficult without cutting other structural reinforcing steel. For ‘lighter’ loads, the post-installed anchor is probably easy and less expensive than having the formwork contractor locate anchors before the concrete is cast.”

Do not connect metal directly to concrete without allowing for expansion and contraction. Direct attachment will result in oil canning, sheet slotting and fastener loosening. “A 20-foot-long panel will grow about 1/8-inch with a 100 degree temperature change,” says Rod Roberts, field services manager, Varco Pruden Buildings, Turlock, Calif. “While this doesn’t seem like much, it will be a big problem. The bottom end of the panel (corrugated vertically type) can be directly fastened, but all fasteners above this location should have clearance holes or mount the panel to a zee-shaped furring angle.”