Thermal performance considerations for aluminum-framed fenestration systems

Aluminum is the material of choice for nearly 90 percent of the non-residential window market due to its strength, lightweight, corrosion resistance, recyclability and ease of fabrication. However, aluminum also has high thermal conductivity. When aluminum extrusions are shaped into framing for window, entrance, storefront and curtainwall systems, a break in the thermal path is necessary between the interior and exterior surfaces. This thermal barrier reduces the transfer of heat through the aluminum, keeping occupants at their desired, comfortable, indoor temperature and maintaining the structural integrity of the aluminum profiles.

Aluminum is the material of choice for nearly 90 percent of the non-residential window market due to its strength, lightweight, corrosion resistance, recyclability and ease of fabrication. However, aluminum also has high thermal conductivity. When aluminum extrusions are shaped into framing for window, entrance, storefront and curtainwall systems, a break in the thermal path is necessary between the interior and exterior surfaces. This thermal barrier reduces the transfer of heat through the aluminum, keeping occupants at their desired, comfortable, indoor temperature and maintaining the structural integrity of the aluminum profiles.

Understanding U-Factor

Thermal performance in commercial fenestration systems is evaluated according to U-factor. Lower numbers indicate better performance and are expressed as a single-number unit followed by BTU/ ft2-hr-F for heat flow per unit area, time and degrees Fahrenheit temperature difference. With all ratings, be careful to know what is being measured. U-factor is a measure of thermal transmittance through conduction, convection and radiation. The three components used to calculate U-factor are center-of-glass, edge-of-glass and frame. Edgeof-glass and frame U-factors can be considerably higher than the center-of-glass values. Size, configuration and sightline affect overall U-factor.

The term U-value may be used by glass manufacturers to differentiate center-of-glass thermal transmittance, from whole window overall U-factor. Be cautious not to consider these terms as interchangeable. Whole window refers to the glazing unit, which is a window or a door, a section of storefront or curtainwall. Whole window overall U-factors are an area-weighted average, required by model energy codes such as the International Energy Conservation Code and ASHRAE 90.1 standard.

Finite element thermal modeling software is used to predict thermal performance of untested or custom systems, or to estimate the performance of specific frame-glass combinations. Center-of-glass, edge-of-glass and frame performance are modeled and combined, forming the basis of National Fenestration Ratings Council (NFRC) labeling programs. NFRC labeling is a compliance option for most state and local codes.

Be certain to check that Division 8 aluminum framing and glazing specifications for U-factor align to meet the specified project requirements as determined by local codes. Using thermal barriers, aluminum-framed systems combined with high-performance glass can achieve overall U-factors below 0.20 BTU/ ft2-hr-F, meeting the need for best-in-class envelope performance in any climate zone.

Types of Thermal Barriers

Types of Thermal Barriers

Following the trend of increasing energy efficient standards and condensation resistance, thermal barrier use continues to grow in popularity. According to the American Architectural Manufacturers Association (AAMA) and Window and Door Manufacturers Association’s

(WDMA) “AAMA/WDMA 2011/2012 Study of the U.S. Market for Windows, Doors and Skylights,” 47 percent of aluminum-framed fenestration systems employed a thermal barrier.

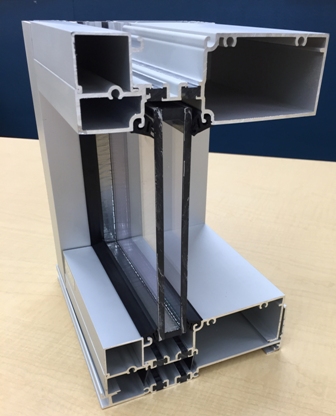

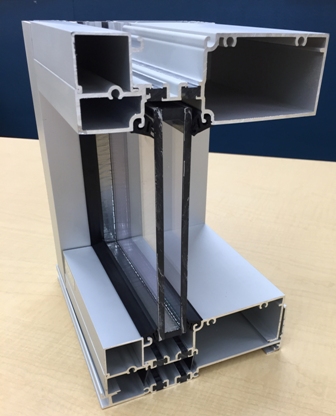

There are two principal types of thermal barriers used in North America: polyurethane poured and debridged, and polyamide insulating strut. The poured-and-debridged method involves pouring a polyurethane-based mixture into the thermal break channel of an aluminum extrusion. The channel’s aluminum surface is conditioned with a lanced, mechanical lock prior to the application of the liquid polyurethane. After the insulating two-part polyurethane cures, the barrier channel is debridged. This step removes the metal bridge from the bottom of the channel to produce a structural thermal barrier between the metal surfaces.

These systems are available in either single- or double-poured-and-debridged thermal barriers in the same aluminum extrusion. These options offer a variety of products to complement the glass selected, designed to meet specific project performance and budget needs.

The insulating strut method involves placing pre-extruded polyamide strips into the thermal break pockets of two separate, inner and outer, aluminum extrusions. These pockets are knurled, a process that produces teeth in the aluminum to bite into the strut, prior to insertion of the polyamide profiles. After the strut is inserted, the aluminum framing member is crimped or rolled, a process that mechanically locks the barrier in place and forms the bond between the two extrusions and the insulating strip to create a structurally secure assembly. Manufacturers product warranties vary greatly, be sure to review before selecting a product. Working with a dependable manufacturer early in the project will ensure the highest quality, reliable thermal performance, within budget and on-time delivery.

—

With more than 30 years of experience with architectural products, Doug Dietrich, AIA, CSI, CDT, serves as Walker, Mich.-based Tubelite Inc.’s architectural accounts representative helping building designers achieve energy efficiency, structural compliance, condensation resistance, blast hazard and hurricane mitigation. He can be reached at ddietrich@tubeliteinc.com. To learn more, visit

www.tubeliteinc.com.