World’s largest pivot doors open new Minnesota Vikings Stadium

U.S. Bank Stadium, the new Minnesota Vikings stadium in Minneapolis, already looks like a winner. One of its most visible, eye-opening features, in addition to its clear, see-through roof is its five, hydraulic, pivoting glass doors on the stadium’s west side. Rotating on hydraulic pistons, they are the largest pivoting glass doors in the world: 55 feet wide and ranging from 75 to 95 feet high, consisting of 30,000 square feet of glass attached to door frames, and weighing, altogether, 40,000 tons.

U.S. Bank Stadium, the new Minnesota Vikings stadium in Minneapolis, already looks like a winner. One of its most visible, eye-opening features, in addition to its clear, see-through roof is its five, hydraulic, pivoting glass doors on the stadium’s west side. Rotating on hydraulic pistons, they are the largest pivoting glass doors in the world: 55 feet wide and ranging from 75 to 95 feet high, consisting of 30,000 square feet of glass attached to door frames, and weighing, altogether, 40,000 tons.

“Enormous,” is the word Steve Berg, author of a book on the new stadium uses to describe the doors. “And very impressive when you see them open,” he adds. “Passing through a door like this is like nothing else you’ve ever experienced.” While the doors contain glass, the active component that supports them is a tubular steel door framework provided and installed by Columbia, Tenn.-based Industrial Contractors Inc. (IDC). As the subcontractor responsible for providing the doors in their entirety, IDC fabricated and provided the steel supporting structure and the operating mechanisms for the doors. IDC also provided the aluminum curtainwall framing and glazing system through subcontract to Egan Co./InterClad, Champlin, Minn. Kawneer Co. Inc., Norcross, Ga., provided the curtainwall. The glass was provided by Vircon Inc., Owatonna, Minn.

Structural steel was the only material choice to fabricate the doors. The door structure was designed with a core truss at the pivot point and cantilevered wings that spanned out to the tips of the doors. The structure was required to carry its own cantilevered self weight plus the significant weight of the aluminum-and-glass curtainwall system, and it was required to resist the design wind loading.

“Hollow structural steel tubes were chosen as the primary framing material to provide the necessary strength, and because they would make an aesthetically pleasing structure,” says David A. Doss, PE, operations manager at IDC. “Welded construction was specified to make the connections blend into the structure. The door glazing was designed to be a continuation of the curtainwall system used on the remainder of the building.”

Door designers included: structural consultant HKS Architects, Dallas; mechanical consultant Thornton Thomasetti, New York City; and infrastructure engineer Hardesty & Hanover, New York City. The general contractor was Mortenson Construction, Minneapolis.

Installation of the curtainwall system was anticipated to be a challenge, as the door structure would deflect as the weight of each piece of the aluminum framing and glass panels were installed. To overcome this obstacle, a system of weights, designed to simulate the curtainwall system, was employed to preload the structure prior to installation of the aluminum framing and glass panels. The weights were connected to the door structure with cables, attached at or near the curtainwall connection points. Weight groupings were designed such that a group of weights could be removed after the corresponding section of framing or pane of glass was installed.

Installation of the curtainwall system was anticipated to be a challenge, as the door structure would deflect as the weight of each piece of the aluminum framing and glass panels were installed. To overcome this obstacle, a system of weights, designed to simulate the curtainwall system, was employed to preload the structure prior to installation of the aluminum framing and glass panels. The weights were connected to the door structure with cables, attached at or near the curtainwall connection points. Weight groupings were designed such that a group of weights could be removed after the corresponding section of framing or pane of glass was installed.

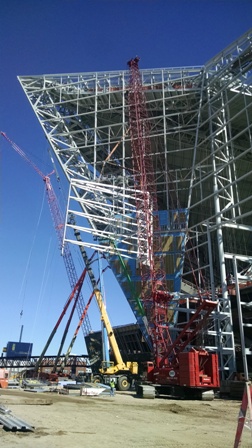

Erection of the doors was a monumental task, due to the size and the configuration of the door structures. “IDC was fortunate to be able to contract the door erection to Danny’s Construction Co., Shakopee, Minn., who set the main truss down the center of the stadium and the other long-span steel,” Doss says. “Danny’s had equipment on-site that was equal to the task and its engineers developed the special lifting apparatus necessary to lift and set the unusual shapes. Each door structure was assembled into two smaller sections on the ground. The lower section was then lifted into position and secured, before the upper section was positioned atop it and the sections welded together.”

When opened, the pivot doors on the Minnesota Vikings Stadium create a seamless transition from the plaza outside to the main building concourse inside. This feature permits the stadium to have somewhat of an open air feel, yet allows the building to be closed up tight to keep out the cold Minnesota winter weather.

When opened, the pivot doors on the Minnesota Vikings Stadium create a seamless transition from the plaza outside to the main building concourse inside. This feature permits the stadium to have somewhat of an open air feel, yet allows the building to be closed up tight to keep out the cold Minnesota winter weather.

Sidebar: U.S. Bank Stadium, Minneapolis

Owner: Minnesota Sports Facilities Authority, Minneapolis

General contractor: Mortenson Construction, Minneapolis

Doors structural consultant: HKS Architects, Dallas

Doors mechanical consultant: Thornton Thomasetti, New York City

Doors bearings, drive machinery and locks designer: Hardesty & Hanover, New York City

Erector: Danny’s Construction Co., Shakopee, Minn.

Subcontractor, door structure and mechanization: Industrial Door Contractors Inc., Columbia, Tenn. www.hangardoor.com

Curtainwall: Kawneer Co. Inc., Norcross, Ga., www.kawneer.com

Curtainwall/glazing installer: Egan Co./InterClad, Champlin, Minn., www.eganco.com/curtainwallglass

Glass: Vircon Inc., Owatonna, www.viracon.com