Roof clamps yield high-holding strengths at cost-effective prices

Roof clamps for metal roofs have become an extremely important component to the metal building industry. They are utilized for various applications: snow retention systems, mounting solar modules, installing satellite dishes, running piping and conduit, securing HVAC units, roof walkway systems and any other accessories that are needed to attach to a standing seam roof without penetrating the roof panels.

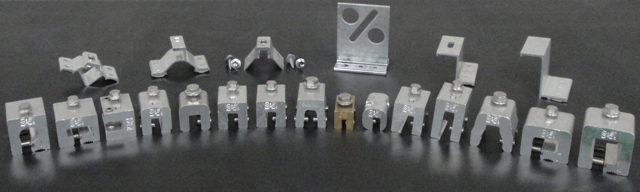

Roof clamps are available in a variety of shapes and sizes to fit various seam profiles currently being manufactured. Clamps are also available is a few different materials (aluminum, brass, stainless steel), and using various hardware (various set screws options or bolts) for securing the clamps to standing seam ribs. However, the most popular clamps are manufactured from aluminum and use bullet-nose set screws. This method of installation yields the strongest holding strengths and at the most cost-effective price since aluminum can be extruded in long sections and cut to length. Brass and stainless steel must be individually machined which increases manufacturing costs significantly. There are clamps that have one, two, or even three set screws which allow one to choose the right size clamp for their application. Single-set screw and double-set screw clamps are the most popular.

Expanding Applications

Over the years, the additional standing seam roof panel seams have grown to more than the standard 16-inch-wide horizontal seams and the 24-inch trapezoidal seams. You now have “T” seams, round bulb seams, inverted “V” seams. Clamp manufacturers have developed clamps specifically for these types of seams. The innovation within our niche market has constantly expanded and will continue to do so to support the metal roofing industry.

There have been numerous attempts by companies to enter the roof clamp market, however buyers need to be aware of companies that might try and use inferior materials or hardware for attaching to the seams. Either full independent lab test have not been performed for pull-off values or the hardware being used could damage your standing seam roof panels and void your warranties. Always check with your roof panel manufacturer for their recommended roof clamp suppliers. Uses for clamps can be broken down to three major categories: snow guards, solar applications and utility use. Below is a list with an overview of each category. Some of the advantages in each category have overlapping highlights.

Snow Guard Systems

Utilizing clamps with your snow guard system is by far the best installation. Your other options are to glue or screw down individual snow guards, with which you will void your roof warranties. With clamps, you achieve great holding strength and a non-penetrating system can be installed anytime of the year. Systems can be purchased to color match your roof color or left in mill-finished aluminum, stainless steel or brass.

Solar Applications

Utilizing clamps with your solar module arrays is again, by far, the best installation. Some solar installers penetrate the standing seam roof panels to attach to the substrate not knowing what should and should not be done to a metal roof. Whether you are using a rail system or direct attachment system, utilizing clamps to attach to the standing seam panel is your best solution.

Utility Use

This category is very broad. The simplest way to explain is that any accessory item that you need to install on a metal roof can be achieved with roof clamps. Signs, walkway systems, banners, satellites, gas/water lines, tie-off stacks, parapet walls, HVAC equipment, lightening protection systems, fascias, equipment screens, antennas, cabling, fall protection systems and more. In addition to roof clamps for the standing seam roof panels, there are a variety of roof brackets available for “R” panel and corrugated metal roof panels. This is important because these brackets should be specifically designed and tested to achieve a watertight attachment using pre-applied sealant tapes under the brackets and neoprene washer-head, self-tapping screws. Using these brackets is a better choice than using older methods of either wood, concrete blocks or screwing down through the roof without properly sealing the penetration.

Clint Funderburk is the vice president of marketing of LMCurbs, Longview, Texas. To learn more, visit www.lmcurbs.com.