Fall protection, building design should work together to prevent worker deaths

Working at heights always involves risk, but the risks increase dramatically when workers are near sharp or leading edges. These two applications present unique risks to workers at height due to the potential for fall protection lifelines to be cut, severed, frayed or otherwise compromised unless workers are equipped with the right gear for those applications.

Working at heights always involves risk, but the risks increase dramatically when workers are near sharp or leading edges. These two applications present unique risks to workers at height due to the potential for fall protection lifelines to be cut, severed, frayed or otherwise compromised unless workers are equipped with the right gear for those applications.

In this article, we will examine what sharp and leading edges are, the dangers they pose and how fall protection providers are responding, as well as how building designers play an important role in keeping workers safe.

When fall protection is built into the design and construction plans, fall hazards are often reduced. Engineers, architects and designers can (and should) do their part to prevent falls from heights by considering fall hazards during the design phase of a construction project, and incorporating embedded safety features into building and worksite designs. In fact, reducing the risks of falls around sharp or leading edges is one of the most important tasks an engineer, architect or contractor can perform because leading edge work is among the most hazardous tasks in steel erection.

Falls are consistently the top cause of fatalities in the construction industry, accounting for 269 of the 775 construction fatalities in 2012, but ironworkers die from falls at a rate 10 times higher than the construction industry average, according to the Center for Construction Research and Training.

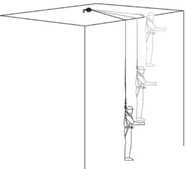

Installing metal decking during the construction of steel-frame buildings is one of the most dangerous tasks an ironworker can perform. It involves spreading metal sheets over narrow structural beams to form the building’s flooring, which constantly creates new work surfaces with potential leading edges with unprotected sides that the ironworker can fall over.

The Occupational Safety and Health Administration (OSHA) defines a leading edge:

Leading edge means the edge of a floor, roof or formwork for a floor or other walking/working surface (such as the deck), which changes location as additional floor, roof, decking or formwork sections are placed, formed or constructed.Although sharp and leading edges are not new hazards, they present complex dangers that workers must understand when working at height.

The Dangers of Leading Edges

A leading edge is a walking or working surface with an unprotected side or edge that creates a fall hazard above a lower level. Ideally, workers should be protected in these situations by a guardrail, netting or fall restraint systems. But in situations where that is not possible and a worker is exposed to the hazard, then some form of personal fall arrest system must be used, such as a self-retracting lifeline device, in the event the worker does fall over the leading edge.

The primary hazards when a worker goes over a leading edge are (1) whether there is enough clearance from the lower level to allow the fall arrest device to engage and arrest the fall before the worker impacts the lower level, and (2) assuming there is enough fall clearance, whether there are any hazards that might injure the worker as the worker swings in a pendulum motion above the lower level after the fall is arrested. And in some situations, the leading edge is also a sharp edge, which creates the additional hazard of the lifeline being frayed, cut or even severed by the edge before it can fully arrest the fall.

The primary hazards when a worker goes over a leading edge are (1) whether there is enough clearance from the lower level to allow the fall arrest device to engage and arrest the fall before the worker impacts the lower level, and (2) assuming there is enough fall clearance, whether there are any hazards that might injure the worker as the worker swings in a pendulum motion above the lower level after the fall is arrested. And in some situations, the leading edge is also a sharp edge, which creates the additional hazard of the lifeline being frayed, cut or even severed by the edge before it can fully arrest the fall.

In addition, there are circumstances when a personal fall arrest system such as a self-retracting lifeline device has to be anchored at foot level instead of above the worker, a common situation if there is no overhead structure to serve as an anchorage point. In such a situation and in the event of a fall over the edge, the lifeline will seldom achieve the required acceleration to lock up during the fall until after the user’s D-ring has passed over the leading edge and is well below the level of the anchor. This means that the user could fall even further before the self-retracting lifeline device engages to arrest the fall, making adequate fall clearance above the lower level even more important.

The Dangers of Sharp Edges

A sharp edge is one that has the potential to cut or sever a lifeline in a fall event-especially if a worker swings like a pendulum after his fall is arrested and the lifeline is strung taught over a sharp edge, sawing back and forth across it.

Because sharp and leading edges are often one and the same, both applications require the same American National Standards Institute

(ANSI)-compliant safety products, made with additional energy-absorbing devices, regardless of whether workers are facing one or both of these hazards.

Building Safety into the Design

Engineers, architects and designers can greatly reduce these risks for workers-and potentially save their lives-by building fall protection systems into their designs and integrating permanent fall protection solutions into buildings. If the upfront planning takes these risks into consideration and incorporates safer anchor points into the design, workers can negotiate leading and sharp edges with less risk.

The National Institute for Occupational Safety and Health

(NIOSH) recommends integrating fall prevention elements into building design by doing the following:

- During retrofits, renovations or new construction, perform a safety design review to identify and consider tasks that could involve fall hazards over the life cycle of the facility.

- Install permanent fall protection features. Depending on when these features are installed during the construction process, they may be used to provide fall protection to workers during the construction phase.

- Many commercial and professional buildings can embed permanent equipment into steel or concrete parts of a building that can be used to set up fall protection systems. These features can be used to prevent falls during construction as well as during building maintenance after construction. Examples include concrete straps, anchor points and guardrail support.

- Ensure that a competent person inspects and evaluates fall arrest systems regularly or damage.

Embedded fall protection safety features have also been shown to save money, according to NIOSH, because fall protection can be set up more efficiently using permanently installed features rather than the added costs associated with installing temporary fall protection each time there are maintenance or renovation tasks to perform.

Case Study: A Fall Protection System for Metal Decking Installation

Since 1999, a structural steel fabrication and erection contractor based in the Northeast has adopted a 100 percent fall protection policy above 6 feet. The company used its fall protection system for metal decking installation in steel buildings: horizontal cables are placed above deck level in preplanned locations that provide the anchor points for the workers’ fall arrest system. As the workers lay decking, the system keeps them protected as they move forward and the leading edge advances. Lanyards with shock absorbers can be attached to any of these horizontal cables.

The system’s effectiveness was evaluated at six sites. Six falls occurred during 59,237 work hours of use in decking installation-an alarming rate of 20.3 falls per 100 full-time equivalent workers. During this evaluation period, the fall protection system was shown to limit falls to a short distance, allowing selfrescue without injury. Two falls that occurred during the installation of the fall protection system also demonstrate the need to ensure fall protection is provided and required during installation of the decking as well. Gravity never takes a break!

[The case study is titled “Evaluation of a Decking Fall Protection System,” by Daniel M. Paine and Michael McCann, Ph.D., CIH. It can be found on the Electronic Library of Construction Occupational Safety and Health, www.elcosh.org.]

Preventing Worst-Case Scenarios

Life-threatening falls are preventable by using the right equipment in the right way, but part of the battle is just getting people to use fall protection in the first place.

Many ironworkers, for example, have been reluctant to use personal fall-arrest systems for fear that harness lanyards could get tangled and cause their own safety problems. According to the International Union of Ironworkers, 25 union ironworkers died between 2000 and 2009 while installing metal decking.

This harrowing statistic underscores the importance of using the correct type of equipment, including leading edge-rated fall arrest systems while working at height around sharp or leading edges.

ANSI Standards for Leading Edges

Standard fall protection gear is almost never appropriate for sharp and leading-edge applications. As a result, product testing and certification organizations in the United States and around the world, including the ANSI, the Canadian Standards Association (CSA) and CE in Europe have been reexamining how lifelines in fall protection systems perform when subjected to these sharp edge applications.

In 2012, a new ANSI standard for self-retracting devices (SRDs) went into effect and, for the first time, a sharp edge test is included in the standard.

ANSI now requires fall protection equipment to pass a series of tests to prove it has enough strength to withstand the force of a foot-level fall that causes the lifeline to bend over and saw across a sharp edge, and this specific test criterion must be met in order for devices to be labeled for leading edge work.

The ANSI standard for sharp edges involves testing the fall arrest device’s lifeline over a piece of steel bar that has a radius of 0.005 inches or less, as typical I-beams have edges with radii ranging from 0.005 inches to 0.032 inches.

All products that are ANSI-compliant for leading edge applications and, by extension, sharp edge applications will indicate on the label that they are rated for “LE.” For example, Capital Safety’s line of sharp and leading edge-rated products use “Edge” or LE in the name.

# # # #

Craig Firl is the North American technical manager with Capital Safety, Red Wing, Minn. Email Firl at cfirl@capitalsafety.com. Capital Safety designs and manufactures height safety and fall protection equipment. It also offers training courses, with 20 operating sites worldwide. For more information, visit www.capitalsafety.com.