The fully automatic Jorns JDB double bending machines from MetalForming Inc., Peachtree City, Ga., are next-generation, fully automated, long folding machines powered by Industry 4.0 Bendex and Jorns J-Bend software.

Q and A feedback on the success of a 40-foot metal bender

They can be configured in lengths from 10.5 feet to 40 feet, and with bending capacities of 18 gauge, 16 gauge, 14 gauge and 11 gauge. The automated up-down bender allows profiles to be created without manual rotation or flipping. This makes production faster, more efficient and cost effective. The added free space geometry allows configuring of complex profiles with more accuracy, while parallel, tapered and overlapped profiles can easily be bent. This increases the speed of your work. The servo-driven hydraulics, automatic loading/unloading, and individually driven clamping fingers allow maximum precision, flexibility and productivity.

Hubbard, Ore.-based The Purlin Mill has been successfully fabricating metal with it and is the first company in North America to have a 40-foot, 11-gauge machine. What follows is information on it by Purlin Mill president and owner Don Branch and Geoffrey L. Stone, founder, owner and CEO of MetalForming, on the Jorns JDB double bending machine operation.

1. What are some of the main drivers behind the Jorns Double Bender?

Branch: Its fabrication capabilities and being able to bend our heaviest existing coil inventory— such as 12-gauge, 72-yield, which is pretty much high tensile—have opened up opportunities for the Purlin Mill. We’ve had a 20-foot Jorns bender and we’ve had a 32-foot Jorns bender. This is the first double bender that I’ve used and it’s nice. I’ve seen double benders work before but nothing at this capacity. It is very accurate at 40 feet.

Stone: It was really refreshing doing business with Don because too many customers when they buy machines buy them for one single thing, when they should be thinking about how they can use the machine to gain new business. Don has been thinking about this new capability and length and profile possibilities and how it can grow his business. He really stepped up in a way that most people don’t step up. He bought more than what was necessary for his specific needs at this specific moment. But he understood that if he had these capabilities he could grow his business. That was something he really thought a lot about and is a smart thing to do.

Branch: Yes, it was a smart thing to do because with this being the first machine with these capabilities in America, and we weren’t sure exactly what we wanted to make.The possibilities are endless. We wanted to make sure that we had those capabilities for whatever we wanted to do in the future. We were so happy we did that because I’ve had other owners of double folders in here to watch it operate and they just can’t believe how efficient it is and its capacity. When they watch it hold on to a heavy-gauge piece and it doesn’t spit out, or light-gauge piece and all the bends are crisp from one 40-foot end to the other. The bend angles are right on the money.

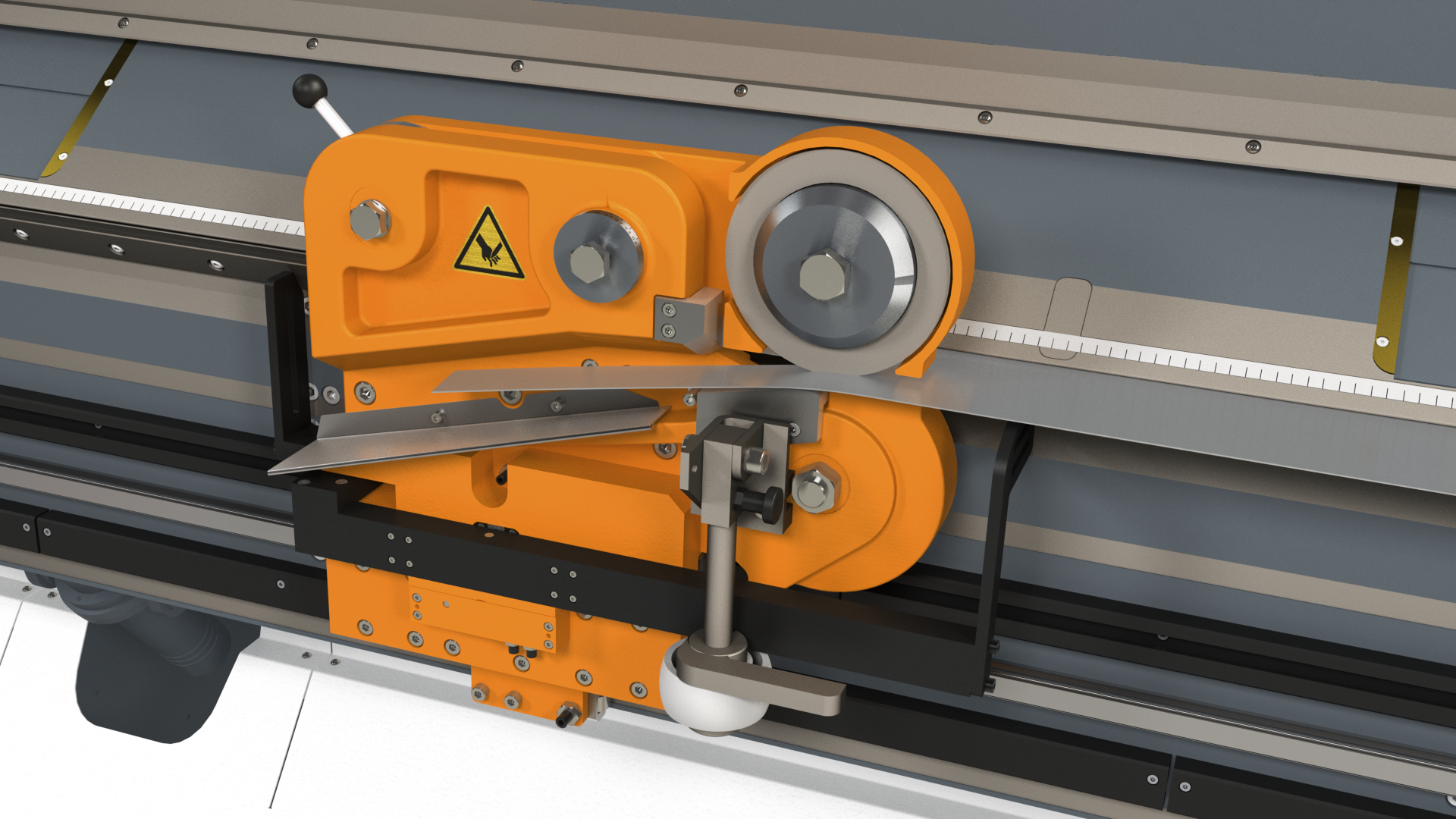

A high-speed slitter.

2. What types of metal construction applications does the Jorns Double Bender excel in?

Branch: Longer lengths with heavier gauge materials and more complex bends. This excels in our architectural products for sure. It handles just about every standard profile for concealed fastener wall panels on the market now. We’ve been making heavy-gauge agricultural valley gutter out of 12-guage material and architectural wall panels for car dealerships. We are bending structural panels and lighter-gauge architectural material.

Stone: It can be used for all kinds of architectural trim products and can be used especially for horizontal wall panels. Don’s application is really useful for custom C’s and custom Z’s for substructural parts. It really covers the whole gamut of architectural needs, from simple building trim to some of the most sophisticated horizontal wall panels imaginable. It’s a very flexible machine.

3. How can it be configured for custom profiles?

Branch: Just a touch of a button and it will be customized.

Stone: The programming is very easy. You can use a lot of off-line programming as the machine is compatible to many CAD systems. You can make any kind of custom profile at least any that will fit around the machines’ geometry. It’s easy.

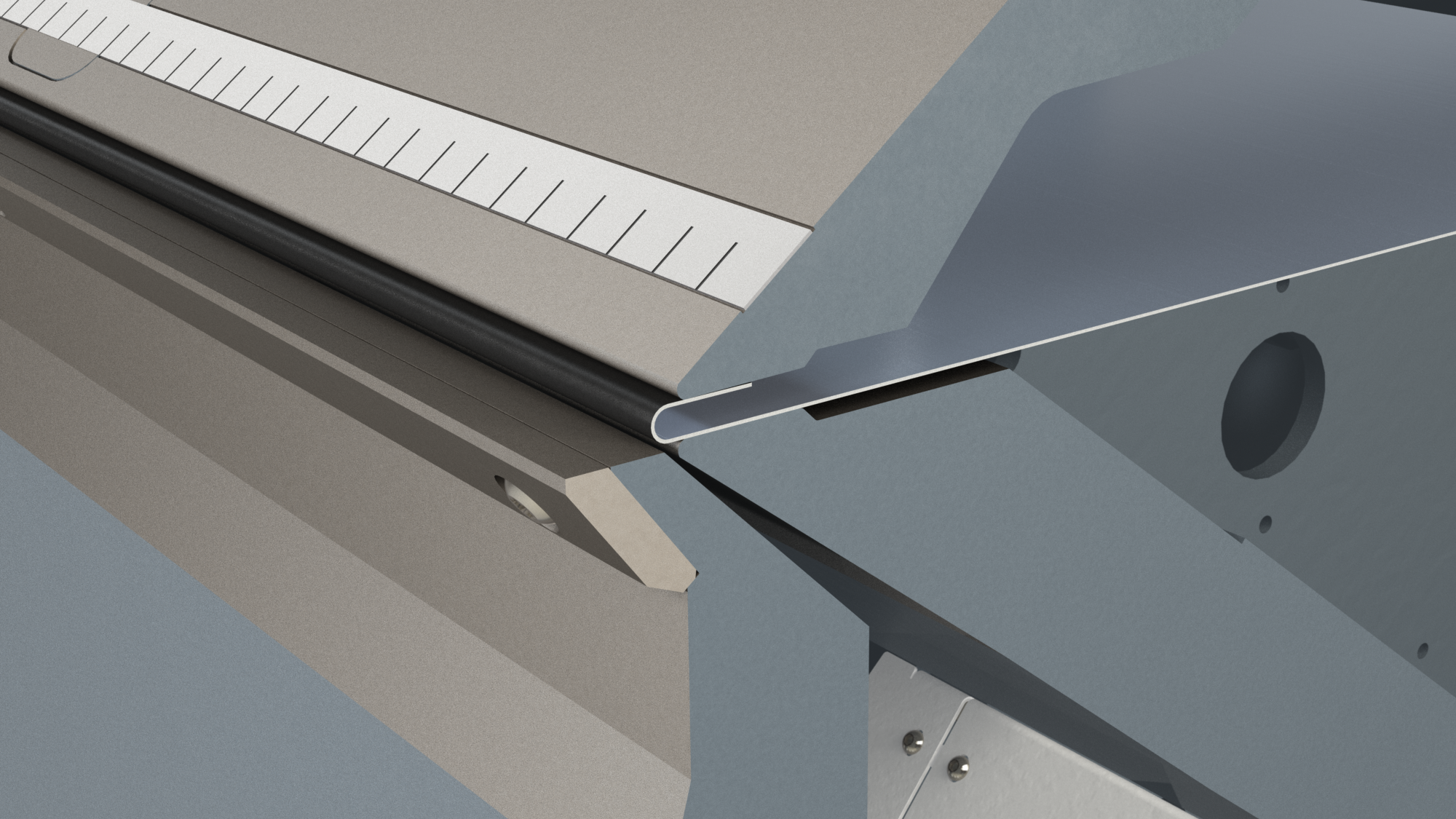

Individual closing dimension for each arm produces precise open hems.

4. Most folders are approximately 22 to 28 feet long. What advantages and product benefits does the Jorns Double Bender increased length to 40 feet long, give it?

Branch: The increased 40-foot length decreases the erection time for the contractor. If you are lapping trims or panels, less end laps will lessen the chances for leaks. If you are running shorter parts you can run multiple parts at the same time. The aesthetics of a single piece versus three pieces lapped together are far more appealing to most people; and less chances for leaks. Stone: If you can install one 40-foot piece, instead of four 10-foot pieces you can certainly install much more efficiently; so the longer the better.

5. What’s different about this machine’s material handling?

Branch: It really depends on the gauges and lengths of the particular job you’re producing. Handling 12-gauge, 40-foot flat sheets is a little different than your lighter gauges. You lay your material on this in-feed table and it automatically takes it in the machine. The machine bends the material and puts it on the table and moves it out for you.

Stone: Also, servo technology allows each individual gripper arm to move independently, which makes it possible to produce tapered parts. Also, Don put a very high-speed slitter on the front of the machine, so you can use the servo grippers to slit the taper first and then bend it. That is a really big advantage. Producing trim without having to use splice plates is very advantageous.

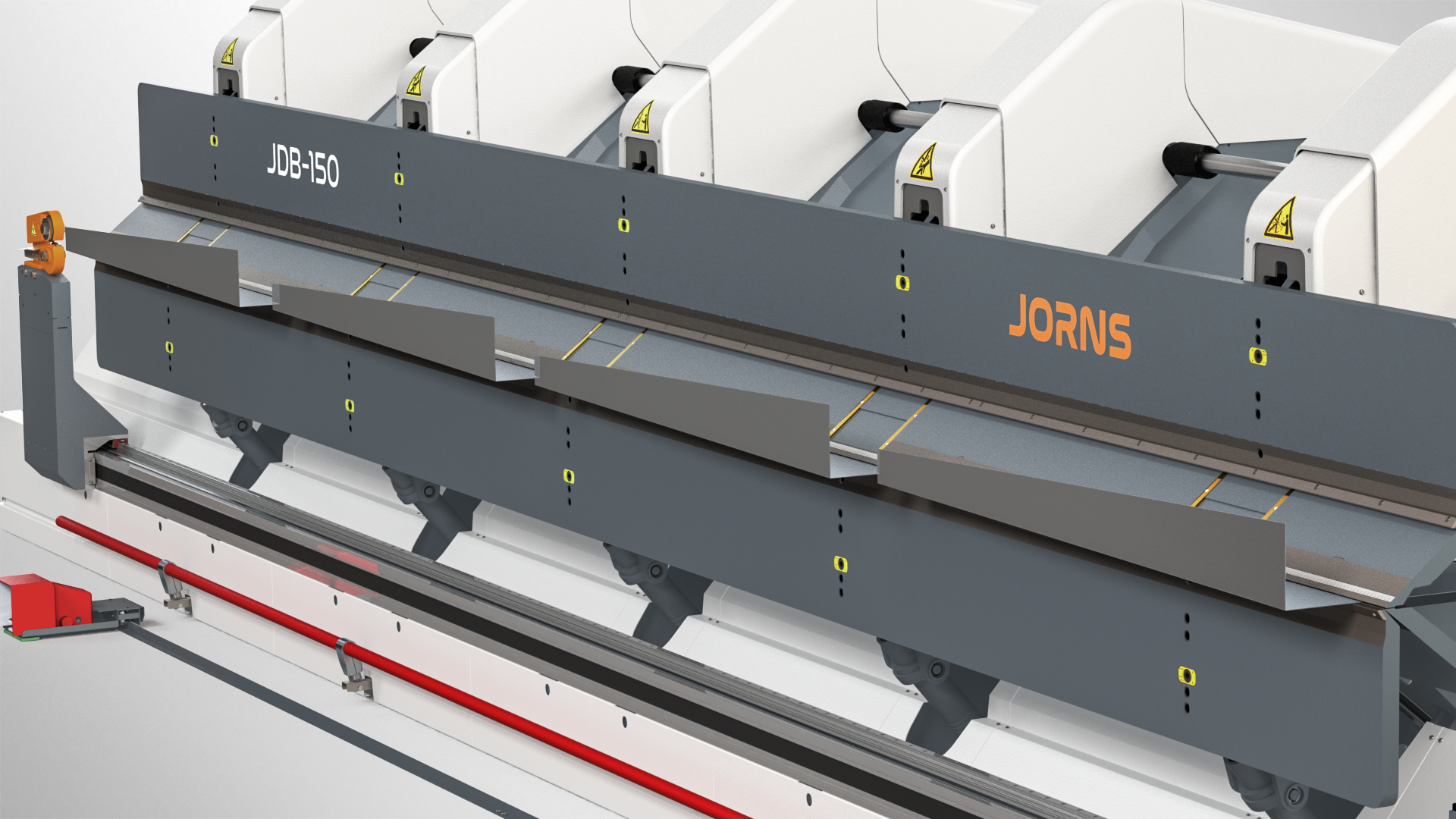

Multi-part clamping system bends three or four identical profiles at the same time.

6. Describe its in-house-developed software (offline programming, the J-Bend app, etc.) and their benefits.

Branch: We can build products in our office on our own computer. We can build the profile and the whole program through the machine in the office. We can send a quote to the customer with a drawing on a sheet of paper that the computer generates. It has a bar code on it. Once the customer agrees to the order and sends it back you take the paper out to the machine and scan it, and the machine automatically sets the parameters to the material and sets the program to the profile on your paper.

Stone: It makes it easy for the customers and they are very impressed with this convenience. It helps with customer satisfaction so customers will want to do business with you again. Secondarily, you’re not slowing down production with all the time it takes to program on the machine. A machine can be running and making parts while someone else can be programming. That’s a massive benefit in terms of total productivity of the unit on any given day.

7. Does the Jorns Double Bender have any limitations?

Branch: All machines have limitations; this machine has few limitations based on the geometry of the tooling.

Stone: The Jorns linear bender can’t bend four-sided parts because there isn’t segmented tooling on the upper jaw. For instance, if you wanted to make four-sided waterproof aluminum panels for a wall façade you can’t do that with this machine. But beyond that, there is an awful lot of versatility so you can produce virtually any typical metal components for building and roofing applications. There are no limitations that cause serious problems with the capability of this machine.

The CP300 Twin graphic control system.

8. What feedback have you received from users regarding the Jorns Double Bender?

Branch: People stand in awe and watch it as it bends and produces parts all by itself. People say, “I’ve never seen anything like this before.” People find it amazing—as I do—that it can bend the same degrees from one end to another at 40 feet.

Stone: The machine has many new technologies including the ability to program each C-frame independently. We have the ability to program the downstroke individually. What that does is it gives you perfect clamping pressure across the part so we can bend the part end-to-end over 40 feet plus or minus one degree. That’s astonishing particularly as the material gets thicker and harder as tensile strength increases.

The feedback we get all the time from users is that customers get enormous increases in productivity and in repeatability. By repeatability I mean from one part to the next to the next, they are all the same. We also get a lot of comments on the increased safety that comes with the operator not being in contact with the metal while its being bent. And more and more, safety is becoming a driver for customers with these automated benders.