Continuous and discontinuous panel manufacturing methods

Over the last 50 years, sandwich panels have evolved as a particularly economical means of construction. The combined materials are always two skin layers (rigid metal facing material or flexible skins such as thin aluminum, paper or membranes, depending on the application) and a core insulating material.

There are basically two panel manufacturing technologies: continuous and discontinuous. In the continuous process, all the used materials are processed together, and the completely formed panel is cut to the desired length without stopping the line. In the discontinuous process, the materials are processed separately; this means the facings are formed and cut to the desired length and then assembled together in a press where the foam is injected.

|

The discontinuous process has a lower level of productivity that cannot be compared with that of the continuous one. It is used today for products with shapes that do not allow the continuous process, or when the production rate required does not justify investment in a continuous line.

A continuous line has an average speed of about 14 meters per minute in production of medium panel thickness (40-50 mm) with metal facings. With one eight-hour shift a day over 220 days in a year, production amounts to about 1,180,000 meters per year, assuming an efficiency of 80 percent. A discontinuous line with a double press 12 meters long, under the same conditions, can reach production of about 100,000 meters per year when working one shift per day.

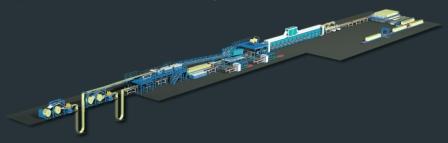

Continuous panel production line

A typical continuous line is made up of the following three sections:

• external layers processing section

• insulating material processing section

• panels handling section

In a typical case of a sandwich panel with both exterior surfaces in sheet metal and an insulating core in polyurethane rigid foam, the first section starts with the sheet decoilers and continues with all the equipment for forming the two sheets into the desired shape. The panel could be a panel for walls or for roofs. Sandwich panels with flexible layers (aluminum, glass fiber sheets, asphalt paper) are not rollformed. Both surfaces of the final panels are entirely flat. The surfaces are pre-heated to the temperature required by the process (usually between 40 and 65 C) and then the insulating material is prepared.

|

In the case of polyurethane (PU-PIR) panels, the foam is generated by starting from the required chemical components metered and mixed together in the foaming machine. The resulting liquid mixture is evenly distributed over the lower metal sheet. The metallic facings, foam and possible side strips or gaskets are pressed inside the double conveyor or continuous press. This machine has to maintain the metal sheets separated at the desired distance while the foam expands.

In this way, the panel will have the desired thickness and shape once the foam has expanded and fully cured. The most critical parameter to ensure a good result from the process is the temperature control of the chemical components, metal sheets and press area. If the insulating material is mineral wool or expanded polystyrene, it is inserted and glued to the metal sheets in the form of mattresses that have been cut and shaped to the right thickness before insertion.

|

Temperature is again a critical parameter, this time for the reaction of the glue, i.e. for good adhesion of the inner board to the external layers. After being formed, the panel is cut, cooled, stacked and wrapped with a plastic film. These last operations can be performed automatically or manually, depending upon the automation level that the customer requires for their production line. Bradbury Group Italy engineering team, Tribano, Italy.

Bradbury Group Italy engineering team, Tribano, Italy. For more information, visit www.bradburygroup.com