Given their critical impact on structural integrity, load distribution, and overall safety, the discourse surrounding the necessity of snow retention systems draws significant attention from designers, contractors, and building owners alike.

One perspective raises concerns about the risks of compromising the building’s structural integrity due to snow accumulation, cautioning excessive snow could exceed the roof’s design load capacity and result in catastrophic failure. Conversely, proponents of mechanical snow retention contend that these systems are essential for effective snow management in a controlled manner to prevent hazardous rooftop avalanches, thereby minimizing safety risks to both pedestrians and property.

So, which approach proves to be the most effective?

Understanding the implications of each perspective is crucial not only to ensure the safety and longevity of the roof but also for public safety. Some support using snow retention only when necessary and encourage planning for “natural” snow shedding to avoid excessive accumulation.

However, this raises critical safety questions: Does “natural shedding” become a safety issue when a rooftop avalanche crushes a vehicle or only after fatalities occur? Also, what happens if ice dams form at eave overhangs, blocking “natural” snow shedding entirely?

Each year, rooftop avalanches cause extensive property damage, personal injury, and even death. This is often due to attempts to remove snow from a roof. The primary function of snow guards is to prevent snow from sliding off the roof in an uncontrolled manner, minimizing the risk of sudden avalanches. A rooftop avalanche endangers people and property whether anticipated or not.

A certifiably tested and engineered snow retention system—specific to the snow loads expected on the metal roof—provides a frictional interface between the roof and the snow, allowing for manageable snow evacuation by thaw and sublimation.

Types of snow guards

Snow guards are a system of components assembled onto a roof surface to immobilize a blanket of snow. There are two primary approaches to restraining snow on a metal roof:

- Continuous systems: These include horizontal components, commonly known as snow bars or snow fences, which are assembled laterally across the roof.

- Discontinuous systems: These consist of individual parts known as snow stops, blocks, or cleats, generally spot-located in some pattern of rows or staggered.

Both systems are typically installed at or near the eaves and may be repeated at intervals up toward the ridge but with greater concentration near the eave area. The appropriate frequency of installation is determined by specific job conditions and load-to-failure characteristics of the chosen devices.

Both types of snow guards rely on the compressive strength of the snow blanket at the interface with the snow guard devices. This strength is greatest at the base of the blanket (i.e. the portion toward the eave and immediately adjacent to the roof surface). The snow blanket is a rather massive slab with significant cohesive strength within itself. Both types of snow guards rely on the cohesive and shear strength of the snow blanket to “bridge” between rows, or laterally from one discontinuous unit to the next adjacent one.

Both types of snow guards have demonstrated satisfactory performance when tested, engineered, and installed properly and adequately.

Misconceptions

A common misconception is snow guards can lead to excessive snow accumulation, potentially exceeding the building’s design structural load capacity. However, an extraordinary, rare weather event would need to occur, combined with conditions exceeding the safety factors built into the design.

The ASCE-7 appendix includes a clause for “slippery roof load reduction” in structural design under very strict conditions. However, many of these conditions no longer comply with other building codes and standards, rendering this load reduction allowance obsolete. While the provision was seldom used, if it were implemented, it would preclude the use of snow guards.

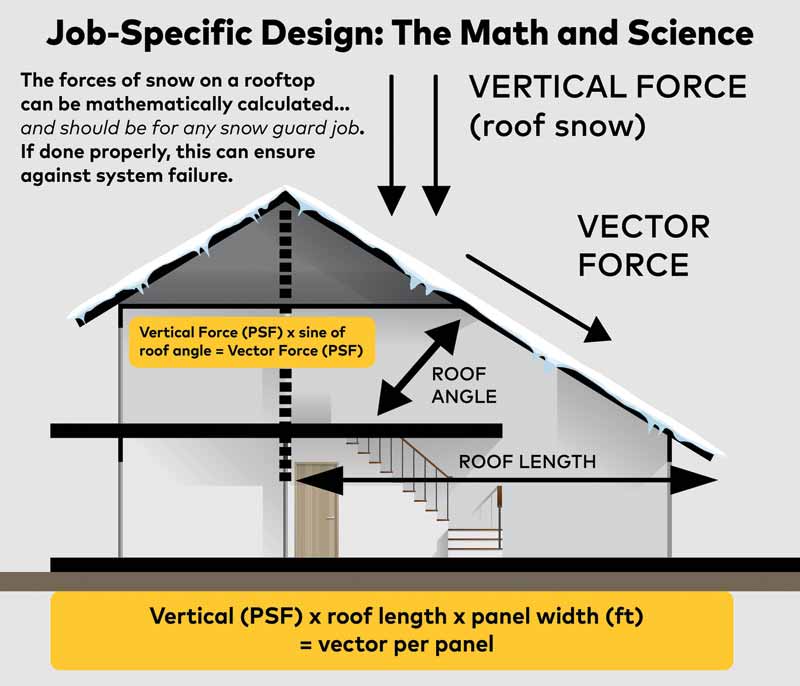

Most snow guard failures stem from under-designed systems that do not adequately account for three basic design factors: design roof snow load, roof angle, and rafter length. To effectively achieve snow retention, it is essential to use a tested snow retention system tailored to these site-specific variables, along with an appropriate factor of safety. Specific testing to learn the failure point and load of the system is an imperative first step, by which the required population can be determined.

Understanding the math and the science

Properly calculating the required population of snow guards is critical for any project. An inadequate population will fail under less-than-design snow loads, while an overly robust population will result in unnecessary costs. The correct design relies on scientific principles and math, rather than guesswork.

The correct population is found by calculating the tributary service loads to be resisted and matching them to the tested, allowable load resistance of the specific snow retention system proposed for the project.

Determining the vector force

The force applied to a snow guard system is a simple calculation but varies widely with the design roof snow load, roof slope, and rafter length from eave to ridge.

For a reliable system design, buyers should require evidence of three quality assurances from the snow guard vendor: certified testing specific to the roof type, certified manufacturing, and proof of engineered calculations.

To retain or not to retain snow on metal roofs?

Taking the approach of natural snow shedding to prevent excessive accumulation becomes a life safety issue as melting snow and ice break loose from their bond to the roof, causing a hazardous rooftop avalanche. Therefore, the “natural shedding” concept can only work safely if pedestrian and vehicle traffic are restricted below the eaves of the building. In a practical context, this is often difficult and, in some cases, just not possible.

A rigorous approach to snow retention system design, emphasizing the importance of a certifiably tested and engineered snow retention system based on precise load calculations for a project eliminates the guesswork and concerns of system overload.

A properly engineered mechanical snow retention system mitigates rooftop avalanches and provides effective snow management in a controlled manner, significantly reducing the safety risks to both pedestrians and property and leaving confidence in a system to last the life of the roof. For more information, download the Metal Construction Association’s white papers, “Metal Roof Design for Cold Climates” and “Qualifying Snow Retention Systems for Metal Roofing” at metalconstruction.org.

Rob Haddock, CEO and founder of S-5! and director of the Metal Roof Advisory Group, is a former contractor, award-winning roof forensics expert, author, lecturer, and building envelope scientist who has worked in various aspects of metal roofing for five decades. S-5! is the first and only snow retention manufacturer to achieve an Evaluation Report of Compliance (ER) with the IAPMO EC 029–2018 industry standard for testing and certifying snow retention devices. For more information visit S-5.com