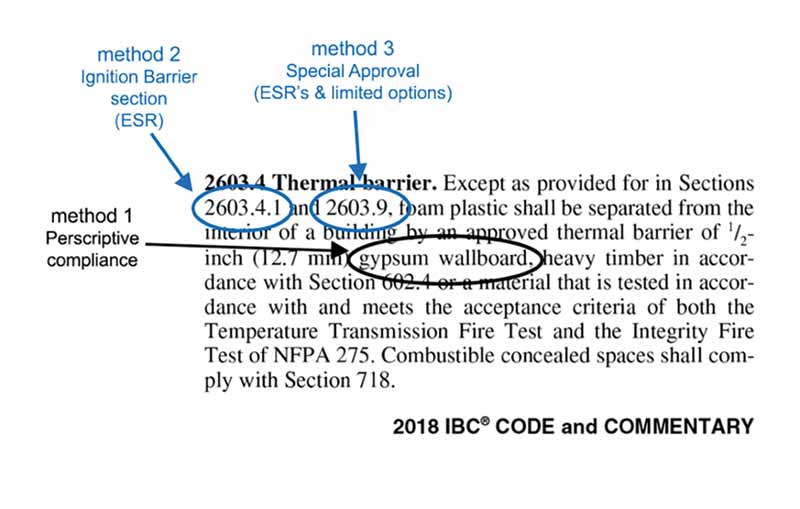

According to the International Building Code, all foam plastics installed in the building envelope require an additional step for a thermal barrier. IBC Section 2603.4 defines thermal barriers and various deviations, derivatives, or direct compliance approaches to allow the safe application of plastics. Methods 1 and 2 are permitted “exceptions” to the thermal barrier code. They use alternate tests and third-party documentation to meet the code in lieu of the thermal barrier requirement.

According to the International Building Code, all foam plastics installed in the building envelope require an additional step for a thermal barrier. IBC Section 2603.4 defines thermal barriers and various deviations, derivatives, or direct compliance approaches to allow the safe application of plastics. Methods 1 and 2 are permitted “exceptions” to the thermal barrier code. They use alternate tests and third-party documentation to meet the code in lieu of the thermal barrier requirement.

Figure 1 illustrates both the prescriptive method and exception methods.

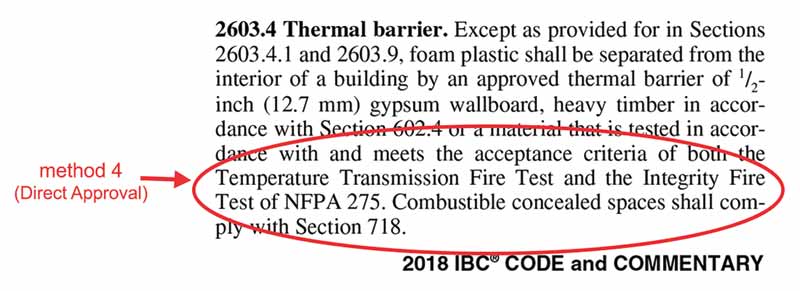

A fourth, more compliant, “equivalent” compliance method also identifies a multi-test test protocol (National Fire Protection Association – NFPA 275) for achieving an equivalent rating to gypsum (Figure 2).

Any product that strives to be equivalent to 12.7 mm (0.5 in) gypsum must meet this protocol.

When an insulation material meets NFPA-275 (Method 4) standards it can also serve as a thermal barrier as well as insulation. If and when this is achieved, “post-added” thermal barriers (for specific use and requiring multiple steps) can be eliminated.

SPF thermal barrier solutions of the past–“post-added” products over plastics

Spray polyurethane foam (SPF) has historically met code by being applied behind gypsum or covered with approved, add-on thermal barriers–items like cellulosic and cementitious materials. SPF could also comply with codes through “exception” methods using lower-level ignition barrier approval (Method 2) or special approval testing (Method 3).

When choosing one of these methods, the questions are:

- Which test(s) should be used?

- Which combination of coatings, cellulose, or cementitious materials should be used?

- Over which foams should they be applied, and at which thickness and densities?

To fully address all these questions and issues is a truly daunting task. Addressing all combinations of SPF/coating/cellulose/cementitious solutions and the appropriate paperwork required by building officials is a separate topic, requiring much further research and explanation. However, understanding the add-on solutions is crucial and needs to be taught—if for no other reason than each skilled trade bears responsibility for the safety of the construction process and the end result.

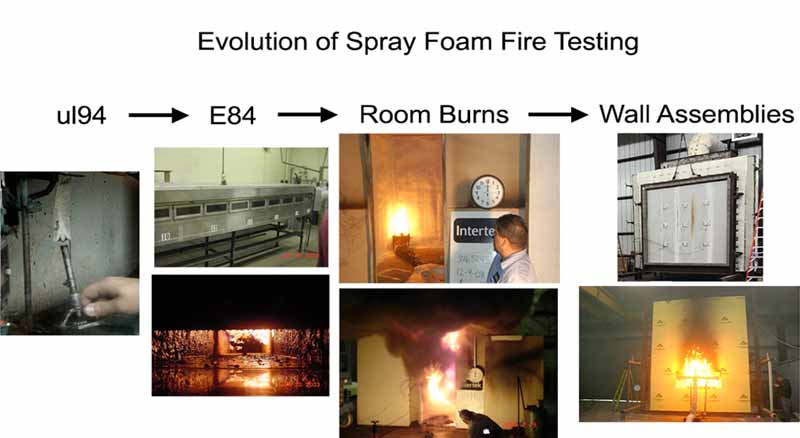

One overriding thought is that manufacturers supplying plastics for the building envelope often claim their products are “fire-rated.” Although this is overly vague and misleading, it is partially correct. All plastics require a minimal fire rating to be allowed for use in buildings. The problem is the robustness of the test procedures referenced.

Figure 3 shows a range of fire tests commonly referenced. A company could claim a “fire rating” from a simple Bunson burner test lasting only seconds to full wall assemblies and ceilings

with multi-hour ratings. Tests lasting mere seconds or claiming “self-extinguishing” with low-level heat or flame impingement provide less than acceptable protection for life safety.

Why my 15 minutes are not your 15 minutes

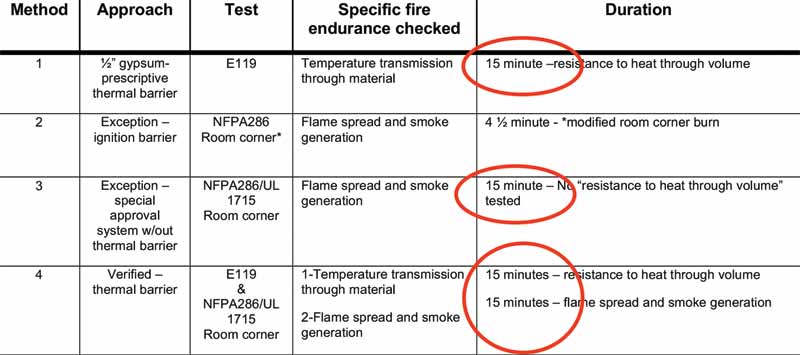

Even when companies claim adequate fire approvals within the jurisdiction of IBC 2303.4 (usually as a function of time), the test behind the measure can be perplexing and/or inaccurately communicated, creating confusion and potential safety violations. A clear example of this confusion is the pass/fail requirements of exception tests (Method 3 – special approval under IBC 2603.9) versus the gypsum approval (prescriptive method) versus the equivalent thermal barriers (Method 4 – direct compliance method) –see Figure 4.

Prescriptive Method 1 (gypsum) follows historical performance results, and fire ratings are 15 minutes based on ASTM E119 temperature transmission testing. This is also sometimes called the compartmentalization of fire test. It tracks and defines the level of time it takes for extreme heat to pass through a wall or ceiling to create a fire-risk situation in adjacent rooms to the space that is compromised by fire.

Exception Method 3 (special approval) defines a 15-minute period where flame spread and smoke generation from a known fire source in a 2.4 m (8 ft) x 3.7 m (12 ft) room cannot exceed certain critical safety levels of flame and smoke. The flame and smoke growth limits within the 15-minute duration estimate a safe amount of time to evacuate the space. Method 3 almost always defines systems’ capabilities that work in conjunction to achieve a lower level but “code-allowed” solution to life safety, as it does not show compliance to temperature transmission risk in a structure. Although both tests have 15-minute durations, they certify two very different life-safety criteria that are not interchangeable. Special approval room corner tests success does not mean the system meets the thermal barrier requirements of IBC 2603.4; it means the system (foam and coating at certain thicknesses defined in the test only) meets the code in lieu of the thermal barrier requirement (thus the exception designation).

Robert Niani, a sprayfoam advisor and current Spray Polyurethane Foam Alliance (SPFA) board member, does an excellent job explaining the specifics of Method 3 exception at this link: youtube.com/watch?v=sNXlBxGssGI.

For direct compliance, Method 4 is a test protocol that requires both the temperature transmission test (ASTM E119) and the flame spread smoke generation test (room corner burns). Both are over a 15-minute period. However, what is being measured and how a pass or fail is defined are significantly different and cannot be compared.

A singular product meeting both the prescriptive solution and the special approval solution protects from both types of fire scenarios. It can only then be rated as an equivalent thermal barrier to the gypsum prescriptive method.

As this section of the code enforces life safety and liability, the builder, architect, or general contractor must understand the various fire-rating methods and what they mean to protect themselves. As with any fire code concern, if an individual is unsure, find a trusted compliance partner, a fire consultant, or a fire inspector.

Richard J. Barone, Jr., is an original founder of Firestable Insulation Company and now serves as executive vice president of marketing operations. His curiosity about fire started quite early, as he was a volunteer fireman at 16 years old. Barone has built up several fire technology companies in his 20-plus years in fire protection, including roles in TPR2 Corporation. Before entering the fire technology world, he spent 13 years at Black & Decker in expanding technical and business management positions, including work with Starbucks, Target Stores, Michael Graves Architects, and Proctor and Gamble.