The primary goal of the construction industry and code development has always been building safety. Whether introduction of innovative new materials or refining construction techniques, minimizing the potential for fire or structural issues has always been a driving motivation for change. Codes and test standards have been revised over the years to reflect these changes. Here is a discussion on one of the most significant fire tests, NFPA 285, and the impact of recent changes.

An updated annex, allows minor modifications to wall assemblies to prevent the need for wholesale retesting.

Why is the understanding of fire so important?

For years, the construction industry has known how to put wall cladding on high-rise buildings. Innovative construction materials and better design methods have led to towering structures identified as construction landmarks, adding to the skyline of cities throughout the United States and the world. Taller and more massive structures, covered with unique and eye-catching wall cladding, have become the norm rather than the exception in the growing urban areas. As these buildings have been designed and constructed, the importance of fire safety has continued to increase to the point where combustibility and flame propagation have become of paramount importance.

In the United States, fire performance requirements have been in place for decades and regulated through implementation of the International Building Code (IBC) and the legacy codes. Quite possibly, the most widely recognized large-scale fire test standard is NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components. Countless articles and presentations have been created to train and reinforce the importance of ignition and flame propagation over the exterior walls should a high-rise structure ever be involved in a fire event.

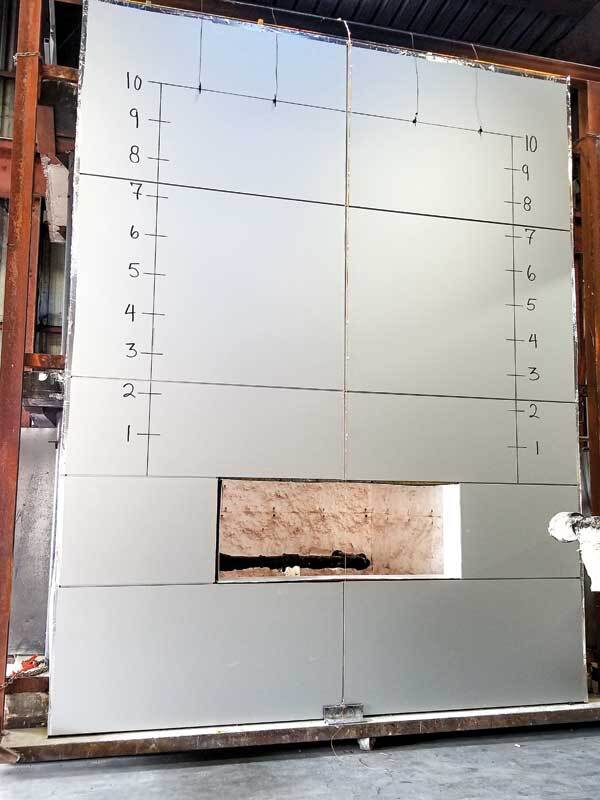

Image 1: A metal wall assembly ready for testing, showing measurements to identify distance flame spread.

In recent years, several fires have taken place throughout the world on high-rise structures leading to huge losses in construction costs and, even more importantly, injury and even loss of life in several cases. Large-scale testing is very common, and while the actual test specimen and procedure may vary from country to country the end goal is understanding the progression of fire and how to maximize fire safety. For this reason, the construction and code community continue to develop better testing to understand fire characteristics and how to limit the damage and loss of life that has been experienced.

What has changed and why?

Going back as far as the first published version of the IBC (2000), NFPA 285 has been a referenced standard test method in the regulation of exterior wall assembly construction containing combustible components. While the basic elements of the standard have remained the same, modifications continue to be made so that the flame propagation can be better understood, and to make the test more closely represent a real-world fire scenario.

During the development of the NFPA 285 standard, which was an evolution from the original full-scale test (UBC 17-6), it was apparent that individual components and the entire wall assembly, as a system, could have an impact on the overall spread of fire. The individual exterior wall components include, but are not limited to, the stud wall cavity, exterior sheathing board, water-resistive barrier (WRB), exterior insulation, support framing system and the cladding itself. Other construction details such as the air cavity (distance behind the cladding that is typically left open to drain excess water from the assembly in a rainscreen type installation) and the framing of openings, among other things, must also be considered to get a full picture of flame propagation.

Image 2: A metal wall assembly with the burner in place before testing starts.

One of the more recent revisions to the 2019 version of NFPA 285 specifies a required location for a vertical and horizontal joint in the exterior veneer of the test specimen. Experience has shown that veneer joints and seams represent a potentially easier pathway for fire to get behind the cladding material and impinge upon other combustible elements within the wall assembly. While joints and seams were generally included in most test specimens, the location was not always in the area of worst fire exposure as may happen in a real-world fire. The NFPA Technical Committee on Fire Tests determined that a worst-case situation would be:

- a vertical joint extending from the center of the window opening (± 12 inches) in the test specimen to the top of the wall and

- a horizontal joint between 1 and 3 feet above the window opening in the test wall running the entire width of the specimen

Prior to this change, there was no standardization of veneer joint location, and several tests may have even been conducted with no joints in the fire area.

Upon adoption and reference of the 2019 Edition of NFPA 285 by the IBC, several wall cladding assemblies were required to be either retested or have the test data re-evaluated to demonstrate compliance, if tested, with the new criteria.

However, one significant problem continued to exist. Even with several facilities able to perform the NFPA 285 test, there was no possible way that every different combination of wall materials could be tested to NFPA 285 due to cost and time required to construct and run the test. An alternative method of analysis, based on successfully tested assemblies, that had been utilized for years needed to be further developed and implemented. This need led to a more structured format used in the Engineering Analysis/Equivalency or Extension.

Image 3: A metal wall assembly showing vertical and horizontal joints prior to flame testing.

NFPA 285 – Guide for Extensions

Even prior to the completion of the 2019 version of NFPA 285, efforts were being made to share nonconfidential material and performance information throughout the design community related to exterior wall design containing combustible components. The goal was to create an annex to the NFPA 285 test standard that contained the most extensive level of information gathered from the collective experience and consensus of many of the fire safety experts during the more than 20 years of testing and continuous maintenance of the NFPA 285 standard. This group of experts met under the NFPA Committee on Fire Tests and followed the NFPA Standard Development Process to create an annex that would be a living document with the ability to be modified as new experience and knowledge becomes available.

The initial plan was to gather design, fire testing and fire protection experts with specific knowledge and a testing history with NFPA 285. The experts gathered at several meetings to share experience on topics such as:

- What would be the impact of substituting certain materials for those that had been included in a successful NFPA 285 test?

- What specific elements had a significant impact on the flame spread in and on the wall including:

- Stud wall design

- Exterior sheathing

- Water-resistive barriers

- Veneer joint design

- Insulation types and thicknesses

- Air cavity dimensions (between the exterior insulation and cladding)

- Floor line firestops

- What specific design considerations were important for exterior cladding materials such as:

- Exterior insulation finish systems (EIFS)

- Aluminum or metal composite materials (ACM/MCM)

- High-pressure laminate (HPL) panel systems

- Insulated metal panels (IMP)

- Fiber cement panels

- Fiber-reinforced plastic (FRP)

- Various types of insulation including mineral fiber based and foam plastic

Each of these topics were discussed, and testing experiences shared amongst a number of the most knowledgeable experts in the field of fire science and building design. The resulting document was included in the 2023 version of the NFPA 285 as Annex B–Guide for Extensions of Results from Assemblies that Meet NFPA 285 Test Requirements

Image 4: The same metal wall assembly as in image 3 after testing.

Again, the goal of the annex is to provide information for the design of alternate systems based on wall specimens that had successfully met to the fire performance criteria of NFPA 285 and this successful baseline test is paramount as a starting point. It has always been understood that not every exterior wall design could actually be tested to NFPA 285; however, with the guidance provided in Annex B of the 2023 NFPA 285 standard, an extension may be developed to account for minor modifications that were deemed as acceptable substitutions when comparing the design assembly to a base wall that had successful met the NFPA 285 test requirements. This alternate design (Extension) could then be submitted to the local authority having jurisdiction as an alternative to NFPA 285 to show compliance with the requirements of the IBC.

(The 2023 version of NFPA 285 has been published and is available through NFPA. Digital access to view-only is available at no charge. All one need do is register for an account (also at no-charge) with NFPA.)

What does the future hold?

While the NFPA 285 test standard and the more recently identified “Extensions” are used to evaluate the fire performance of wall assemblies, new materials and construction practices will continue to be developed by the design community. By keeping the NFPA 285 standard updated and understood by the construction community, structures that meet the fire safety requirements of the International Building Code and other local codes can continue to meet the safety standards that have come to be required in the United States.

Andy Williams is a registered professional engineer with more than 35 years’ experience in the design and construction of exterior wall assemblies. He has worked primarily in the areas of curtainwall, ACM/MCM and HPL construction and has been involved with fire testing development and materials since the early 1980s. Williams is a member of ICC, ASTM and the NFPA Fire Test Committee, and has participated in development of the Model Codes, various standards, and the IBC. Williams is the principal consultant for Panel Cladding Solutions LLC and serves as the director of codes and standards for the Metal Construction Association.