Advances in technology have come a long way in making our lives easier. And while contractors and builders may be slow to adopt new technology, the benefits it can bring to the job site cannot be understated.

Advances in technology enhance construction safety and productivity

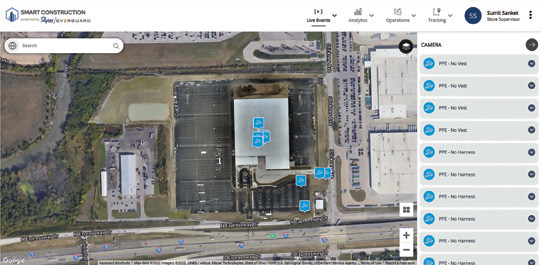

Equipment location provided by BLE and GPS tags displayed on the Zyter dashboard. (Photo courtesy of Rudolph Libbe Group)

In recent years, project management software helps contractors save time and be more productive on the job site. Drones allow aerial views and 3-D scans of the job site and surrounding areas without endangering any workers. Phones can be used to scan barcodes and check in material. iPads make it easy to pull up drawings and orders without having to go back to the trailer or lug around a laptop on the job site.

There are many types of technology that can help make the job site safer and more productive. We spoke to a few contractors and builders to get an idea of where they are currently with using technology on the job site.

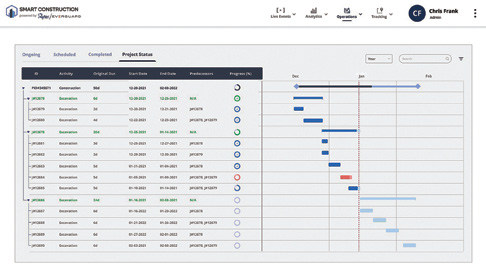

Task management view of project status displayed on the Zyter dashboard. (Photo courtesy of Rudolph Libbe Group)

Project Management

Last year Arthur E. Hance, president, Hance Construction Inc., Washington, N.J., says the company implemented a new project management system that automates a lot of the record-keeping for their superintendents. “The software gives our superintendents a much easier platform for daily reports and for reporting job conditions. It automatically inserts the weather, whereas usually guys would have to have a thermometer in the job trailer, write down different temperatures. This automatically goes out to the weather service and imports it into the job report.”

Danielle Hernandez, business development and marketing at Hammers Construction, Colorado Springs, Colo., notes that the company also recently transitioned to using a digital platform for their daily reporting and safety reports. “In the past, we’ve required our superintendents to use paper forms which they would turn in at the end of the day,” she says. “Our new program works with phones, iPads and laptops and allows supers to take updated pictures, upload documents and report safety incidents without having to take time to come into the office.”

The construction management software also gives crews more flexibility in accessing drawings by using a tablet on-site. “The ability to be on the job site and be able to call up a drawing on a tablet is extremely useful,” Hance says. “Rather than going back to the truck, pulling out a set of drawings, laying them out on the tailgate, digging through them, now you can just stand there and pull up the drawings while the person is asking you the question. There’s definitely a time saving element to it.”

“Since implementing the program we’ve seen a high increase in accountability from our superintendents,” Hernandez adds. “If a daily report is missed, office staff can see this. It also helps a great deal when there’s an issue or delay on site. Uploading the pictures and sending reports to the owners is a great way to keep them informed on the progress of their building.”

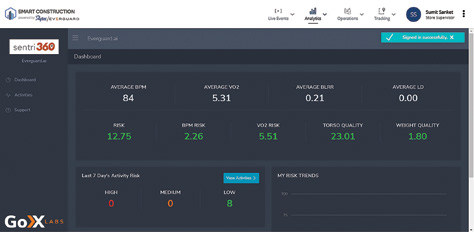

Dashboard showing current worker physiological and mechanical biometrics. (Photo courtesy of Rudolph Libbe Group)

Drones

Using drones on the job site can help with everything from data collection to identifying structural defects, conducing site surveys, live streaming walkthroughs and more. Hernandez adds that they’ve been using video and still photos from their drone to take progress pictures and to survey sites.

Hance adds that his company has been using drones for the past two years for a variety of applications. “They’re great for doing inspections of roofs and things without putting people in harms’ way,” he says.

Automated Systems

As a Butler Builder, Hance Construction has been able to use Butler’s automated system on their phones to check in the steel deliveries. “Using Butler’s automated system allows us to check in the steel when it arrives on the job site,” Hance says. “We’re able to read the barcodes on the steel, and the program automatically updates what’s been delivered to the site.”

Having used Butler’s software for approximately the last three years, Hance says it makes it much easier to verify what steel has been shipped. It’s also a lot safer, as the workers used to have to climb all over the steel loads to check everything in.

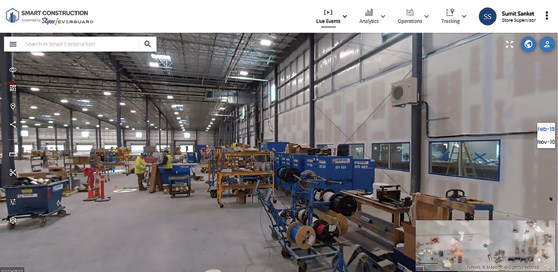

Live video feed of construction site from AI Smart Visio cameras. (Photo courtesy of Rudolph Libbe Group)

Connected Worker Safety

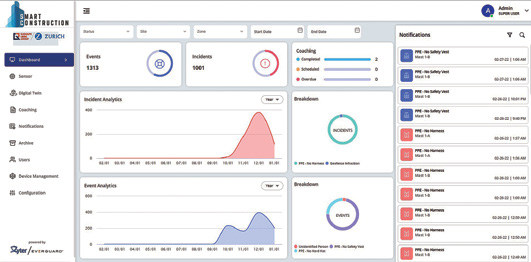

In October 2021, full-service contractor Rudolph Libbe Group, Walbridge, Ohio, started beta testing a collaborative solution from Zyter Inc., Zurich North America, Qualcomm Technologies Inc. and Everguard.ai to advance the use of AI-based Internet of Things (IoT) technologies to enhance construction safety. Using best-in-class technologies and risk knowledge, the project provides construction managers a 360-degree view of construction sites and real-time alerts regarding workers’ adherence to safety regulations. The goal is to help prevent job-site incidents and accidents that can result in serious injuries and costly property damage.

For this project, Zyter integrates its SmartSpaces Smart Construction IoT platform, analytics and front-end dashboard with Everguard’s Sentri360 AI platform, which is made possible through Qualcomm’s Smart Cities Accelerator Program and Qualcomm IoT Services Suite. Everguard provided environmental sensors, camera equipment and the computer vision technology, while NavVis provided point cloud scanning and 3-D photos, and Tag-n-Trac provided sensors for tracking equipment. Zurich monitors the impact and evaluates the solution for use with other construction customers.

The connected worker safety experiment spans several cases leveraging cameras, computer vision, sensors and smartwatches to capture data from the workers and the equipment at one Rudolph Libbe job site. The goals include understanding how watches and software provide real-time feedback to individuals, as well as seeing how durable watches and pods are and how they stand up to construction work. Another objective is to see if real-time feedback provided will encourage associates to take more control of their own health and safety, while learning if leading-edge technology can make a job site safer and more productive.

Brad Deal, senior vice president, construction services at Rudolph Libbe Inc., a Rudolph Libbe Group company, explains, “Safety excellence is our core value at Rudolph Libbe Group, and these experiments are an opportunity to test how computer vision, sensors and artificial intelligence can be used together to benefit our associates and customers. Our connected worker safety experiment will ensure that we are at the forefront of technological advances to work more safely.”

Zyter dashboard view of worker safety analytics and current notifications. (Photo courtesy of Rudolph Libbe Group)

Company Buy-In

When it comes to incorporating new software and technology into your company, it’s important to be sure everyone is on board. “Involve staff in the process of selecting the new technology but recognize that many people may be resistant to change,” Hance explains. “When management decides to implement new technology, to whatever extent possible, involve staff and put together a plan for that implementation. Set up a schedule of how to do it and then manage that schedule.”

It’s also important to take the time to train staff. As Hernandez notes, it took a while for some of their staff to get used to the change, but the program is very easy to use, and after some training the responses have been positive.

Additionally, Hernandez says she personally believes technology on a job site is essential. “A lot of construction companies who have been in the industry for several years tend to be set in their ways and are reluctant to try new something new. Technology allows for better communication with office and field staff, higher levels of accountability and creates a safer workplace environment. Today’s tools can save a lot of time and money in the long run.”